parts and function of cnc machine CNC milling machines are a big part of the manufacturing industry. This is due to their efficient and accurate production of parts of a CNC. Each part of these machines plays an important role in the general functionality. CNC . Precision CNC Machining Parts Service & Custom CNC Machined Parts Manufacturer. Bergek CNC is good at making prototypes, small-batch, or mass-production customized CNC machined parts. Come to get instant quotes on metal and plastic machined parts.

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

2 · main components of cnc machine

3 · cnc machine spare parts list

4 · cnc machine parts list pdf

5 · cnc machine parts list

6 · cnc machine parts diagram

7 · block diagram of cnc machine

CNCPros.com offers a wide variety of parts designed to fit your Fadal like Ballscrews, ATC clips, spindles, resolvers, amplifiers, inverters and more – all on-the-shelf, ready-to-ship today! Lowest prices on the things you really need.

Understand the parts and functions of CNC machines. From controllers and motors to tool holders and coolant systems, get a detailed explanation of each component to enhance your knowledge. In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF. CNC machines consist of several key components and elements that contribute to their functionality and efficiency. Here, we will explore the .

CNC milling machines are a big part of the manufacturing industry. This is due to their efficient and accurate production of parts of a CNC. Each part of these machines plays an important role in the general functionality. CNC .

CNC machine parts and their function – An overview . A milling machine is made up of many CNC machine parts and their function makes them increasingly essential for it to work. The CNC milling machine has a vast and . The main parts of the CNC machine are: (i) Input Devices: These devices are responsible for inputting the part program into the CNC machine. . Functions of CNC Machine. The fundamental role of CNC is to oversee and .

Understanding the Function of a Spindle in CNC Milling. The spindle is one of the most important parts of a CNC milling machine that provides power to maneuver and cut material. It consists basically of a rotary shaft, which is driven by an electric motor that rotates at high-speed giving torque for effective interaction with the workpiece .

CNC milling machines are one of the most popular tools for machining metals to get the desired workpiece. These rigid and powerful machines consist of various parts that work in synchronization to perform the desired milling operation. CNC Machine Parts By Type of Technology. CNC machines can be classified by their technological capabilities. Each type uses different parts to achieve specific machining operations. Below, we will discuss the components of 3-axis and 4-axis CNC machines. 3-Axis CNC Machines. 3-axis CNC machines are the most common type used in various industries. Welcome to a fascinating journey into the inner workings of CNC machines! In this article, we will take a detailed look at the anatomy of a CNC machine, exploring its main parts and functions. Whether you are a seasoned CNC operator or someone new to

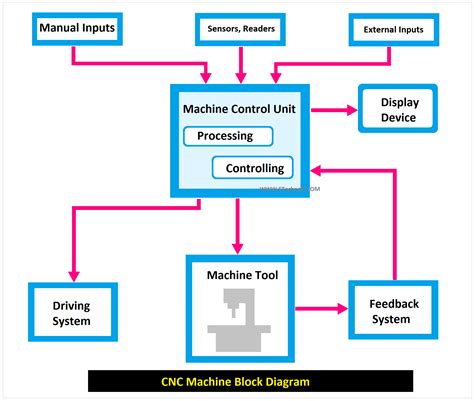

CNC Machines and its Components - Download as a PDF or view online for free . Basically, it is control of machine tools by numbers. Functions automated by NC system - Starting and stopping of machine tool spindle. . Universal machining centre - Main parts of CNC machining centre are bed, column, spindle, table, servo mechanism, tool . The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions.What are the Parts of a CNC Machine? Bed: Typically constructed from cast iron for enhanced durability and strength, the bed is the machine’s foundation, supporting all components.. Spindle: Inside the machining area, the electrically driven spindle rotates tools that cut and shape the parts. The inside of the spindle is tapered to match the tapered angle of the tool holder to .

Type of CNC Machine Main Function Common Applications; CNC Milling Machines: Material removal using high-speed cutting tools: . irregular profiles. 4-axis CNC machines are commonly found in applications involving complex cylindrical or curved parts. Multi-Axis CNC Machines. Multi-axis CNC machines, as the name suggests, can move in four or . Main Components (Parts) of CNC Machine. A CNC (Computer Numerical Control) machine is a sophisticated piece of equipment used in manufacturing and machining processes to automate and control the movement of tools and workpieces with a high degree of precision. . The primary function of the spindle servo system is to facilitate the cutting . Defining the CNC Machine Parts. The following are the fundamental parts of a CNC machine:. Control Panel: It is the mind of this computer numerical control machine that has been used to input instructions as well as keep an eye on its working condition; it contains a programming interface, diagnostic function, and manual control switch.

The main components of CNC machine are, and The following represent the various cnc machine components:- #1. Input Device. These are the device that is used to input part programs in a CNC machine. There are three commonly used input devices, & these are punch tape readers, magnetic tape readers, and computers via RS-232-C communication. In CNC machining, there are two primary types of milling machines: the vertical milling machine, with a Bridgeport milling machine being an excellent example, and the horizontal milling machine. Although the milling operations .

Why CNC Milling Machines Parts are important. CNC milling machines consist of many parts, with around fifteen key components. Important parts include the CNC controller, spindle, work table, tool changer, and coolant system. These components work together to perform precise machining tasks. Each part of a CNC mill plays a vital role in its . CNC machines use computer programs to control the functions and motions of the machine’s tool. Programs are prepared ahead of time (or auto-generated from a solid model) and contain coded alphanumeric data that the . 4. HISTORY 1955 - US Air Force define a need to develop a machine tool capable of machining complex and close tolerance aircraft parts. 1959 - MIT is the contractor and builds the machine for the project. MIT announces Automatic Programmed Tools (APT) programming language 1960 - Direct Numerical Control (DNC). This eliminates paper tape and allows .It performs all the controlling action of the CNC machine, the various functions performed by the MCU are. It reads the coded instructions fed into it. It decodes the coded instruction. It implements interpolation ( linear, circular and helical ) to generate axis motion commands. . This is all about what is CNC machine-parts, block diagram .

CNC Lathe Machine Parts and Working Principle Understanding CNC Lathe Machine Parts. A centre lathe machine consists of several essential parts, each playing a crucial role in its operation. The main components include the spindle, chuck, tailstock, carriage, and bed. The control functions of CNC-run mills and lathes are similar, with the programming language often being G-Code. CNC lathe machines typically consist of two axes, X and Z, enabling them to work with a variety of materials. . With their ability to produce highly precise and custom-made parts, CNC machines play a crucial role in ensuring the .CNC lathe machines are intricate and complex systems that rely on a combination of various parts and functions to deliver precise and efficient machining. Understanding the key components discussed above will help operators, technicians, and enthusiasts grasp the inner workings of these machines and unleash their full potential.

What Are the Main Parts of a CNC Machine? 1. Machine Control Unit (MCU) MCU is the core of the CNC machine. They perform all the machine’s controlling functions, including reading the coded instructions, decoding them, and implementing interpolation. 2. Input Devices. The input devices are used to input the program into the CNC machine tools.Study with Quizlet and memorize flashcards containing terms like Why were many companies slow to develop numerical control technology in the 1950s?, The development of the minicomputer converted numerical control technology to ______. A. punched paper tape B. automated numerical control C. computer numerical control D. programmed codes, A major .CNC Milling Machine Parts. There are various components of the general CNC milling machine. Let’s see them one by one. 01. Column. The column in case of the CNC Machine is to provide the support and structure to the other machine components. Column acts as a support structure for the milling machine.

The CNC Lathe Machine:Beyond Parts and Functions . Aside from the primary attributes outlined,a CNC lathe machine can perform many more advanced operations. Understanding the parts and their functions is the first step towards mastering the use of this machine. Remember that practice and experience are equally important for becoming proficient .Apart from these, a bed, spindle, worktable, axis, and control panel are common parts of this CNC machine. CNC Plasma Cutters: CNC plasma cutters are amazing when cutting hard materials into shapes and parts. CNC plasma cutters use a plasma arc that is very hot to cut metal. With a plasma torch, these CNC machines cut steel and aluminum in .

schematic diagram of cnc machine

parts made by cnc machine

main components of cnc machine

We uphold a consistent level of professionalism, quality, credibility and repair for CNC Lathing Parts, Custom CNC Parts , Aluminum Prototype , CNC Turning Machined Mechanical Part , .

parts and function of cnc machine|main components of cnc machine