6 axis cnc machine part examples Among the groundbreaking innovations, 6-axis CNC machines have revolutionized the way complex parts are fabricated. In this blog post, we will delve into the world of 6-axis CNC . A consignment box in the military is a standard-sized container used to transport and store various types of military equipment, supplies, or personal belongings. These boxes are typically made of sturdy materials like metal or wood and are designed to be easily transportable by land, air, or sea.

0 · what is 6 axis machining

1 · haas 6 axis cnc

2 · cnc machine axis locations diagram

3 · cnc machine axis identification

4 · 6 axis milling machine

5 · 6 axis machining center

6 · 6 axis cnc milling machine

7 · 6 axis cnc machine price

A cutman is a person responsible for preventing and treating physical damage to a fighter during the breaks between rounds of a full contact match such as a boxing, kickboxing or a mixed martial arts bout.

If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping. 4-axis: Includes a .

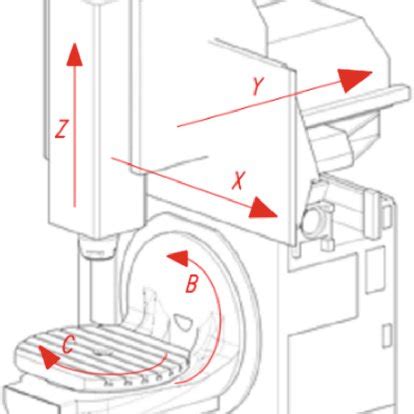

What are the 6 Axis on a CNC Machine? To answer this question it is possible to explain how CNC machines evolved from 3 to 6-axis versions. The simplified image of a 6-axis CNC with its moving parts and their motion types .

what is 6 axis machining

haas 6 axis cnc

Among the groundbreaking innovations, 6-axis CNC machines have revolutionized the way complex parts are fabricated. In this blog post, we will delve into the world of 6-axis CNC .6-axis CNC machines combine cutting-edge technology with advanced milling capabilities to handle the most intricate designs effortlessly. From engine blocks to aerospace components, .The additional axis on a 6-axis CNC machine can create complex shapes and improve machining capabilities. Other configurations may have the main advantage of 6-axis machines, but the speed and ability to significantly .6-Axis CNC Machining. 6-axis CNC machining takes complexity to a new level by adding a rotational axis. These machines are typically used for highly intricate parts requiring extreme precision. Suitable for parts with highly detailed .

This article will describe the different parts of a CNC machine. Some parts are common between lathes and mills, like the control unit, driving system, and feedback system, while others are specific to a certain type of .The below portfolio provides some examples of our CNC multi-axis machined parts and showcases our expertise in creating high-quality parts using both vertical CNC machining and .Applications of 6 Axis CNC Machines: Aerospace industry: Precision machining and complex part production. Automotive industry: Advanced prototyping and component manufacturing. . 6 axis CNC: A 6 axis CNC machine is a type of CNC machine that can move and rotate its cutting tool or workpiece in six different directions. It can perform complex and precise operations that are impossible or difficult with conventional CNC machines.

If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping. 4-axis: Includes a secondary tool carrier for rapid material removal. 5 & 6-axis: Adds additional Y and sometimes B-axis for complex milling. What are the 6 Axis on a CNC Machine? To answer this question it is possible to explain how CNC machines evolved from 3 to 6-axis versions. The simplified image of a 6-axis CNC with its moving parts and their motion types indicated is shown in the image below.Among the groundbreaking innovations, 6-axis CNC machines have revolutionized the way complex parts are fabricated. In this blog post, we will delve into the world of 6-axis CNC machines, understanding their capabilities, applications, and significant advantages.

6-axis CNC machines combine cutting-edge technology with advanced milling capabilities to handle the most intricate designs effortlessly. From engine blocks to aerospace components, these machines ensure optimal performance and impeccable precision.The additional axis on a 6-axis CNC machine can create complex shapes and improve machining capabilities. Other configurations may have the main advantage of 6-axis machines, but the speed and ability to significantly decrease production times make the latter a clear winner.6-Axis CNC Machining. 6-axis CNC machining takes complexity to a new level by adding a rotational axis. These machines are typically used for highly intricate parts requiring extreme precision. Suitable for parts with highly detailed features and tight tolerances, such as aerospace components or high-end consumer electronics.

This article will describe the different parts of a CNC machine. Some parts are common between lathes and mills, like the control unit, driving system, and feedback system, while others are specific to a certain type of machine. For example, tailstocks and headstocks are only found on CNC lathes. 1. Input DeviceThe below portfolio provides some examples of our CNC multi-axis machined parts and showcases our expertise in creating high-quality parts using both vertical CNC machining and Swiss multi-axis turning techniques.Applications of 6 Axis CNC Machines: Aerospace industry: Precision machining and complex part production. Automotive industry: Advanced prototyping and component manufacturing. Medical devices and implants: Intricate and personalized designs. Robotics: Enabling intricate movements for robotic arms. 6 axis CNC: A 6 axis CNC machine is a type of CNC machine that can move and rotate its cutting tool or workpiece in six different directions. It can perform complex and precise operations that are impossible or difficult with conventional CNC machines.

cnc machine axis locations diagram

If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping. 4-axis: Includes a secondary tool carrier for rapid material removal. 5 & 6-axis: Adds additional Y and sometimes B-axis for complex milling. What are the 6 Axis on a CNC Machine? To answer this question it is possible to explain how CNC machines evolved from 3 to 6-axis versions. The simplified image of a 6-axis CNC with its moving parts and their motion types indicated is shown in the image below.Among the groundbreaking innovations, 6-axis CNC machines have revolutionized the way complex parts are fabricated. In this blog post, we will delve into the world of 6-axis CNC machines, understanding their capabilities, applications, and significant advantages.6-axis CNC machines combine cutting-edge technology with advanced milling capabilities to handle the most intricate designs effortlessly. From engine blocks to aerospace components, these machines ensure optimal performance and impeccable precision.

The additional axis on a 6-axis CNC machine can create complex shapes and improve machining capabilities. Other configurations may have the main advantage of 6-axis machines, but the speed and ability to significantly decrease production times make the latter a clear winner.6-Axis CNC Machining. 6-axis CNC machining takes complexity to a new level by adding a rotational axis. These machines are typically used for highly intricate parts requiring extreme precision. Suitable for parts with highly detailed features and tight tolerances, such as aerospace components or high-end consumer electronics.

This article will describe the different parts of a CNC machine. Some parts are common between lathes and mills, like the control unit, driving system, and feedback system, while others are specific to a certain type of machine. For example, tailstocks and headstocks are only found on CNC lathes. 1. Input Device

The below portfolio provides some examples of our CNC multi-axis machined parts and showcases our expertise in creating high-quality parts using both vertical CNC machining and Swiss multi-axis turning techniques.

cnc machine axis identification

6 axis milling machine

6 axis machining center

6 axis cnc milling machine

CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

6 axis cnc machine part examples|6 axis milling machine