what does chem only mean on a sheet of metal The term sheetmetal only describes thickness, and does not inform as to width, chemistry or tensile properties. Coils produced at sheet-steel mills typically measure 1000 to 2000 mm wide, with some aluminum mills capable . There should be a label on the inside of the box cover. If that's missing, there's a model number on the back of the timer mechanism. Push the tab up on the upper left and pull the timing mechanism out.

0 · sheet metal terminology

1 · sheet metal grades explained

2 · sheet metal fab terms

3 · sheet metal definition

4 · how does sheet metal work

5 · can chemetal be scratched

There are many ways to cut sheet metal, which one you need to use depends on the project. The following is a primer of tools and techniques for cutting sheet metal. The most important factor to consider when working with .

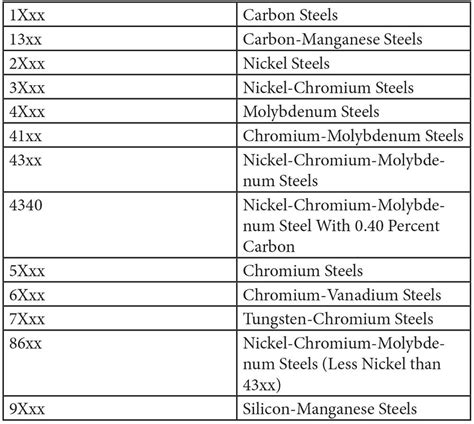

Steel specifications were first written, before World War II, by the Society of Automotive Engineers’ (SAE’s) Iron and Steel Division in collaboration with the American Iron and Steel Institute (AISI). These days, AISI no longer writes specifications that . See moreLike steel alloys, the aluminum alloy numerical designations distinguish one alloying family and composition from another. Unlike steel . See moreFor the most part, the relationship between chemistry and tensile properties is limited. As an example, take two paper clips, each with . See moreStainless steels are iron-based alloys containing at least 10 percent chromium. A transparent, chromium-rich oxide film forms on the surface, which limits further oxidation, or rusting. . See more

The term sheetmetal only describes thickness, and does not inform as to width, chemistry or tensile properties. Coils produced at sheet-steel mills typically measure 1000 to 2000 mm wide, with some aluminum mills capable .If it is a Chemetal product with an HPL backer, it can be bent along a gentle curve. If the product is metal only, you can usually get as tight a radius as you want. Chemetal can create custom . But the good news is you only need to learn a handful of common fabrication phrases to communicate like a true sheet metal services expert. With these words, designers, engineers, and buyers can collaborate optimally and . Sheet Metal Terminology, Definitions & Phrases 2021 [Updated] Sheet metal terminology is important for beginners to understand. Below is a list of common vocabulary terms. Working with sheet metal involves many .

We want to bring you into the fold, so we’re sharing 30 common sheet metal fabrication terms and what they mean. Let’s talk shop! Sheet Metal Fabrication: The term “sheet metal fabrication” encompasses the manufacturing processes .Here is an ultimate guide on galvanized steel and metal sheets that can be used for roofing, HVAC, construction products, and more. Learn more before you make your purchase from a supplier near you.Chemical etching is a technique used to produce intricate metal components by selectively removing material from a metal sheet using chemical agents. Chemical conversion coating is often referred to as chem film chromate coating or yellow chromate coating. This is a coating process that applies chromate to the metal. It creates a. surface that is corrosion resistant .

Principles & practice of chemistry explained by Chemists & Scientists who bully around electrons on the molecular merry-go-round. Pan-Chemical "Tour of Italy." Chem-adjacent sciences: biology, pharmacology, physics, etc are welcome. Fielding questions from all: general audiences, interdisciplinary peers, professionals in allied fields, etc. For the most part, the relationship between chemistry and tensile properties is limited. As an example, take two paper clips, each with identical chemistry. Bend one back and forth a few times, but leave the other intact. .

Can chemical conversion coatings be used on non-metal materials? Chemical conversion coatings are primarily designed for metal substrates due to the reactive nature of the coating process. They may not be . The Definition and Meaning of the Triangle Symbol in Chemistry. In chemistry, the triangle symbol (∆) represents heat energy, specifically indicating that heat is either being added to or removed from a reaction. Why does chem treat stain happen? The defect usually occurs because of a clog in the line, a broken wiper or a miscalculation of the wiper roll. Surplus Metals Corp purchases defect and secondary coils and if you need to sell coils please reach out today. Chem treat stains are going to be impossible to remove on such a large scale such as mill . What does casting mean? Casting is the act or process of making objects or parts in a foundry by pouring molten material into a mold. This metal is then allowed to cool and solidify (solidification), taking the shape of the mold. The four main steps in casting are: Metal heating and melting; Pouring the molten metal; Metal solidification

metal sheets and sheets with a low pressure laminate backer added cannot be rolled. The exception: 24” wide designs with low pressure laminate backer. ® Product Reference Chemetal Product Reference Thickness (in inches) Magnetic and Dry Erase Sheet Size Base Metal HPL Phenolic Metal Weight sq ftThe point is that fluorescence does not mean the sheets are dirty. It means that a fluorescent substance is present. If you assume that only semen has ever touched the sheet and subsequently find a fluorescent spot, yes, that's still semen. You can't separate the fluorescence from the substance which fluoresces. Yes it is a physical change. The only other option is chemical change and the metal didnt change its chemical make up, it only changed its shape, and shape is the only thing that did change.

I couldn't find this answer in a food dictionary, but "sheet" as a verb can mean "to fall, spread, or flow in a sheet" (Merriam-ster Dictionary). When making jelly you want to cook the mixture until it reaches the consistency where, when you dip a cold metal spoon and allow the mixture to fall, the jelly will slide together and hang off the .Plata o plomo is a Colombian Spanish slang phrase that translates to “silver or lead.” A person saying the phrase is telling the listener to either accept a bribe (plata, meaning “silver,” a common slang term for money in Colombia) or lose their life (plomo, a metonym for “lead bullet”). These include changing tool and die dimensions, chemistry variation, furnace temperature fluctuation, and different cooling rates, to name only a handful. While these variations are typically small, they must be considered. . this could mean the purchaser wants a metal sheet that is 48.00000000 inches by 96.00000000 inches. This level of .

Alodine, Chem film, and Chromate Conversion Coating are essentially the same under different names. These are treatments applied to metal surfaces, particularly aluminum, to enhance corrosion resistance and provide a good primer for paint adhesion. This process not only extends the life of the metal but also maintains its aesthetic appeal.Chemical etching is a technique used to produce intricate metal components by selectively removing material from a metal sheet using chemical agents. It is therefore considered a subtractive process —that is, it involves the removal of material from a workpiece to achieve the desired design or shape, in contrast to an additive process , where . The authoritative public forum for Metal Finishing since 1989 -----Cleaning of chem-film conversion coating (Alodine, Iridite, etc.)? Q. I have an aluminum part that has an Alodine 1201 ⇦ this on eBay or Amazon [affil links] .Metal basis ignores the non-metal contents like chloride. But it tells you that there is only a very small amount of other metals e.g. niobium, iron, etc.. present. For many applications the metal impurities are more important and low level of other metal .

cnc machine glass cutting

A chemical conversion coating is a surface treatment applied to metals in which the metal undergoes a chemical reaction at the surface. This chemical reaction transforms the metal surface into a thin protective layer. When applied to .Sheets of Nirosta stainless steel cover the Chrysler Building. Microscopic close-up of mild steel sheet metal. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Metal Clad means that each individual circuit breaker or switch is in its own dedicated cubicle, in a "draw-out" unit made of sheet metal on all sides. The draw-out unit then slides into a sheet metal frame and has more sheet metal on all sides. The unit has stabs on the back that will engage the bus bars in the frame.

Anodizing can apply color to the metal or be applied as a clear finish. Anodizing in its modern form has not changed drastically since sulfuric acid anodizing was introduced in 1927. Its longevity is a testament to the strength of the process. Anodizing sheet metal is a perfect application for preventing scratches and wear.What Does Clad Metal Mean? Clad metal is a composite of two or more dissimilar metals, metallurgically bonded together, to achieve improved functional characteristics, better than those available in a single metal or alloy. The bonding can be achieved by use of one of the various methods, including extruding the two metals, diffusion bonding, pressing or rolling sheets .

/ Metal Rods, Shapes & Sheets / Sheet Metal Solid Expanded Perforated Aluminum Cold rolled steel Steel Brass Stainless steel Copper-plated aluminum Tin 18-in 24-in 30-in 36-in 48-in 1/16-in 1/8-in 1/2-in Hot dipped galvanized Plain Zinc-Plated Hillman IMPERIAL 5 4Study with Quizlet and memorize flashcards containing terms like What does it mean if a metal is an alloy?, Often used as one component in an alloy, increasing its strength. A. copper B.zinc C.Nickel D.Aluminum, Commonly used in alloys to enhance corrosion resistance A.Nickel B.Chromium C.Titanium D.Zinc E.A&C F.C&D and more.The chemical treatment leads to a protective oxide layer, or passivation film, that is less likely to chemically react with air and cause corrosion. Passivated stainless steel resists rust. Video: What is Passivation of Stainless Steel? What Does Passivated Stainless Steel Mean? What Is a Passivated Finish? By "radio waves" I mean waves used for radio transmission appliances, e. g. within 1 MHz to 10 GHz. If the size of the metal sheet makes a difference, please answer for a infinite sheet and a fridge. If the distance from the emitter to the sheet matters, please provide an answer for several wavelength, half wavelength and flush on the surface.

A Sheet Metal Worker, or Sheet Metal Technician, works with thin sheets of metal to produce and install various types of products. On a typical Sheet Metal Work job description, their listed duties may include measuring and marking raw materials, cutting sheet metal to desired sizes using specialized equipment and fastening sheet metal into place via soldering, . What is Gauge in Sheet Metal Fabrication? In the fabrication industry, ‘gauge’ is an identifier for the standard thickness of sheet metal of a specific material. The gauge size is based on the weight of the metal sheet and is inversely proportional to the thickness, which means the higher it is, the thinner the sheet metal is.

sheet metal terminology

sheet metal grades explained

sheet metal fab terms

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

what does chem only mean on a sheet of metal|sheet metal grades explained