electric pull box size This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According . This self-guided tutorial provides a step-by-step approach for users to learn NX 12. It is intended for those with no previous experience with NX. However, users of previous versions of NX may also find this tutorial useful for them to learn the new user interfaces and functions. The user will

0 · standard electrical pull box sizes

1 · pull box standard sizes

2 · nec box size chart

3 · junction box sizes chart

4 · electrical pull box calculator

5 · electrical box size chart

6 · electrical box size calculator

7 · distance between underground pull boxes

Shimano EW-RS910 Di2 Bar End Junction Box Features: Frame mount or bar-end mount options; 2x E-Tube ports; Integrated charging port; Single function button with LED .

standard electrical pull box sizes

Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact us or call 800-767-1576 if you need .How to Calculate Underground Pull Box Sizing; Determining Proper ANSI Load .

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For .

china cnc prototype machining

This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According .The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in . Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on . Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances .

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example.

Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According to the NEC (National Electrical Code), different rules apply for straight and angle pulls.The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side. Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances between pull boxes & their locations.

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example.

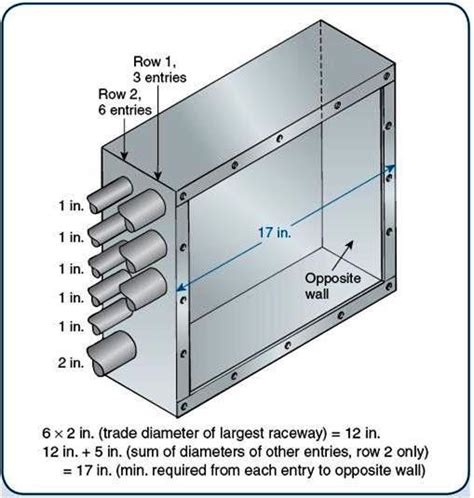

Make sure you know the proper sizing requirements for pull boxes, junction boxes, and conduit bodies to avoid damaging the conductor insulation when installing conductors 4 AWG and larger. Courtesy of www.MikeHolt.com. Based on the 2020 NEC.

Effortlessly calculate the required electrical pull box size for your wiring project using our Electrical Pull Box Size Calculator. Input the number of conductors and select the box type to get accurate results.

Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According to the NEC (National Electrical Code), different rules apply for straight and angle pulls.The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull.

Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side. Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances between pull boxes & their locations. Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example. Make sure you know the proper sizing requirements for pull boxes, junction boxes, and conduit bodies to avoid damaging the conductor insulation when installing conductors 4 AWG and larger. Courtesy of www.MikeHolt.com. Based on the 2020 NEC.

china cnc precision turning parts suppliers

TORCHSTAR 6 Inch Ultra-Thin LED Recessed Light with Junction Box, 3000K Warm White, 12W 100W Eqv. Dimmable Slim LED Downlight, ETL and Energy Star Certified, Pack of 4The Bazz under-cabinet junction box for direct wiring is compatible with all Bazz halogen products and Bazz. Note: junction box can't be enclosed or behind a wall where it is .

electric pull box size|electrical box size calculator