cnc machine aluminum diy How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach. Discover how choosing the right metal sheet can transform your projects, whether it’s construction, manufacturing, or artistic endeavors. By the end, you’ll have a clear understanding of which metal sheet suits your needs best and why.In this article, you'll learn different types of welding processes with their working, advantages, disadvantages, applications, and more.

0 · machine to make your own

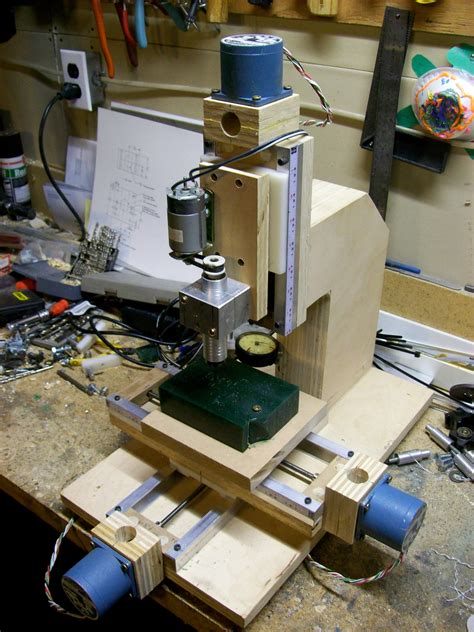

1 · homemade cnc milling machine plans

2 · homemade cnc machine plans

3 · home built cnc milling machine

4 · cutting aluminum with cnc router

5 · cnc machine to cut aluminum

6 · build your own milling machine

7 · build your own cnc mill

Explore the eight most common electrical enclosure types and how they’re used. From NEMA ratings to materials, we give you the basics.

With the corner pieces a heavy (well relatively lightweight; it's all aluminium) frame was bolted together. The square frame made from the smaller profiles were mounted with 4 milled blocks .The machine is almost entirely built from 15mm thick aluminum plate and .Aluminum Cnc Router: This Instructable is not going to be a step by step build log . How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach.

The machine is almost entirely built from 15mm thick aluminum plate and 30x60mm aluminum extrusions. I built this CNC router using a very limited .To build your DIY CNC aluminum milling machine, you'll need to gather various components. In this chapter, we will provide you with a comprehensive list of components, including stepper .

Building a DIY CNC aluminum milling machine requires specific materials and tools. This section will guide you through the process of sourcing the necessary components, including structural .Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, .

machine to make your own

IndyMill is a project started by Nikodem Bartnik as an upgrade of Dremel CNC machine. The basic idea behind this project is to create easy to build CNC machine that anyone around the world can reproduce. Using popular, easily . A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.With the corner pieces a heavy (well relatively lightweight; it's all aluminium) frame was bolted together. The square frame made from the smaller profiles were mounted with 4 milled blocks (aluminium) on the inside of the Maytec profiles.

All you need is a kit, compressed air and a bit of oil. The whole package will cost you under 0 (assuming you have an air compressor), so if you use your router reasonably often it’s a really smart upgrade. While it definitely is my preferred way to cut it, there are a few alternatives that also work great.

How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach.The machine is almost entirely built from 15mm thick aluminum plate and 30x60mm aluminum extrusions. I built this CNC router using a very limited amount of tools. The main tools I used were a drill press and a lathe.Aluminum Cnc Router: This Instructable is not going to be a step by step build log of my machine, but an overview of my design and what I learned over the course of this build. Hopefully I can share a few things to help with your CNC build.To build your DIY CNC aluminum milling machine, you'll need to gather various components. In this chapter, we will provide you with a comprehensive list of components, including stepper motors, linear guides, spindle motors, and control systems.

Building a DIY CNC aluminum milling machine requires specific materials and tools. This section will guide you through the process of sourcing the necessary components, including structural elements, stepper motors, linear guides, and electronics.Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, instructions, and Bill of Materials. Fastest path to ownership.IndyMill is a project started by Nikodem Bartnik as an upgrade of Dremel CNC machine. The basic idea behind this project is to create easy to build CNC machine that anyone around the world can reproduce. Using popular, easily available components is only .

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.With the corner pieces a heavy (well relatively lightweight; it's all aluminium) frame was bolted together. The square frame made from the smaller profiles were mounted with 4 milled blocks (aluminium) on the inside of the Maytec profiles.All you need is a kit, compressed air and a bit of oil. The whole package will cost you under 0 (assuming you have an air compressor), so if you use your router reasonably often it’s a really smart upgrade. While it definitely is my preferred way to cut it, there are a few alternatives that also work great.

How to build a DIY CNC Milling machine from scratch that can cut aluminium and steel.My objective for this project was to design and build a CNC milling mach.

The machine is almost entirely built from 15mm thick aluminum plate and 30x60mm aluminum extrusions. I built this CNC router using a very limited amount of tools. The main tools I used were a drill press and a lathe.

Aluminum Cnc Router: This Instructable is not going to be a step by step build log of my machine, but an overview of my design and what I learned over the course of this build. Hopefully I can share a few things to help with your CNC build.To build your DIY CNC aluminum milling machine, you'll need to gather various components. In this chapter, we will provide you with a comprehensive list of components, including stepper motors, linear guides, spindle motors, and control systems.Building a DIY CNC aluminum milling machine requires specific materials and tools. This section will guide you through the process of sourcing the necessary components, including structural elements, stepper motors, linear guides, and electronics.

Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, instructions, and Bill of Materials. Fastest path to ownership.IndyMill is a project started by Nikodem Bartnik as an upgrade of Dremel CNC machine. The basic idea behind this project is to create easy to build CNC machine that anyone around the world can reproduce. Using popular, easily available components is only .

homemade cnc milling machine plans

24 gage sheet metal thickness vs paper

homemade cnc machine plans

Electrical boxes encase wire connections to protect them from short circuits. They are vital for fire safety and are used for receptacles, ceiling fans, outside outlets, and more. Unless the device is one of the few that contains its own wires, it likely will need an electrical box.

cnc machine aluminum diy|build your own milling machine