cnc machine how many axis The capabilities of CNC machines largely depend on their axis configurations. The number and type of axes dictate the complexity of parts the machine can produce. Here’s a quick look into the most common CNC . In order to install an electrical outlet and circuit from scratch you need a roll of 14-2 or 12-2 Romex® cable (depending on how much load you need from the outlet) and either a new work box, or an old work box.

0 · what is 5 axis machining

1 · cnc mill axis diagram

2 · cnc machine axis identification

3 · cnc axis explained

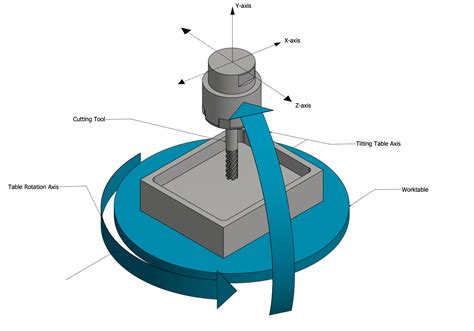

4 · 4 axis cnc milling machine

5 · 4 axis cnc mill

6 · 3 axis cnc milling machine

7 · 12 axis cnc machine

There's only one product that is supposed to be code approved that can be buried. You are correct, a junction box must be used and must be accessible and covered.

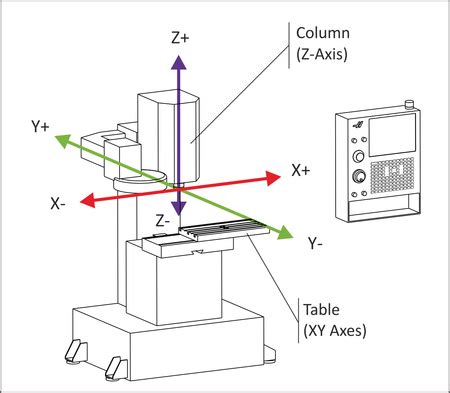

3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping. The capabilities of CNC machines largely depend on their axis configurations. The number and type of axes dictate the complexity of parts the machine can produce. Here’s a quick look into the most common CNC .

Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even .CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth). While the number of axes can vary depending on the specific machine and its purpose, typically, a CNC lathe will have two to four axes. The most common configuration for a CNC lathe is two-axis, known as X-axis and .

3-axis routers are the most basic CNC machines, but they are also extremely capable and suitable for many applications. As the name implies, they operate on three axes: . Learn about CNC machine axis counts, including the types of axes and how they are incorporated in the creation of 2-axis, 3-axis, 4-axis, and 5-axis CNC systems. Scan2CAD Blog

3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping. The capabilities of CNC machines largely depend on their axis configurations. The number and type of axes dictate the complexity of parts the machine can produce. Here’s a quick look into the most common CNC machine axis layouts—3-axis, .

what is 5 axis machining

Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even controlling more than 10 axes.CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth). While the number of axes can vary depending on the specific machine and its purpose, typically, a CNC lathe will have two to four axes. The most common configuration for a CNC lathe is two-axis, known as X-axis and Z-axis. The X-axis is the horizontal axis, which runs parallel to the lathe spindle. 3-axis routers are the most basic CNC machines, but they are also extremely capable and suitable for many applications. As the name implies, they operate on three axes: the X-axis, which moves left-to-right; the Y-axis, which moves front-to-back; and the Z-axis, which moves up-and-down.

One crucial aspect of CNC machines is the number of axes they possess, which significantly impacts their capabilities. In this blog post, we will delve into the world of CNC machines and explore the different axis configurations available, helping you understand how many axes you really need for your specific needs. I.One fundamental aspect of CNC machines is the number of axes they operate on. In this blog post, we will delve into the different axis configurations commonly found in CNC machines and discuss how to determine the optimal number of axes for your specific needs. II. Exploring the Different Axis Configurations\ 1\. Description and applications\ 2\.

Learn about CNC machine axis counts, including the types of axes and how they are incorporated in the creation of 2-axis, 3-axis, 4-axis, and 5-axis CNC systems. Scan2CAD Blog

3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping. The capabilities of CNC machines largely depend on their axis configurations. The number and type of axes dictate the complexity of parts the machine can produce. Here’s a quick look into the most common CNC machine axis layouts—3-axis, .

Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even controlling more than 10 axes.CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

While the number of axes can vary depending on the specific machine and its purpose, typically, a CNC lathe will have two to four axes. The most common configuration for a CNC lathe is two-axis, known as X-axis and Z-axis. The X-axis is the horizontal axis, which runs parallel to the lathe spindle. 3-axis routers are the most basic CNC machines, but they are also extremely capable and suitable for many applications. As the name implies, they operate on three axes: the X-axis, which moves left-to-right; the Y-axis, which moves front-to-back; and the Z-axis, which moves up-and-down.

cnc mill axis diagram

One crucial aspect of CNC machines is the number of axes they possess, which significantly impacts their capabilities. In this blog post, we will delve into the world of CNC machines and explore the different axis configurations available, helping you understand how many axes you really need for your specific needs. I.

online cnc machining course

ontario baby box distribution

Junction boxes are commonly used during alterations and additions to an installation. With certain exceptions regulation 526.3 requires that every connection shall be accessible for inspection, testing and maintenance.

cnc machine how many axis|3 axis cnc milling machine