cnc 7 axis machine In simple terms, 7-axis CNC machines offer the ultimate capability for producing detailed and complex parts swiftly and accurately. Whether you’re in aerospace, automotive, or medical . Unless it says somewhere in the instructions that you need a thermal cutoff, you should be able to bypass it. There are a few ways you could wire the fixture up using the existing housing and they would not all reuse the whip that went to the existing can.

0 · y axis cnc lathe

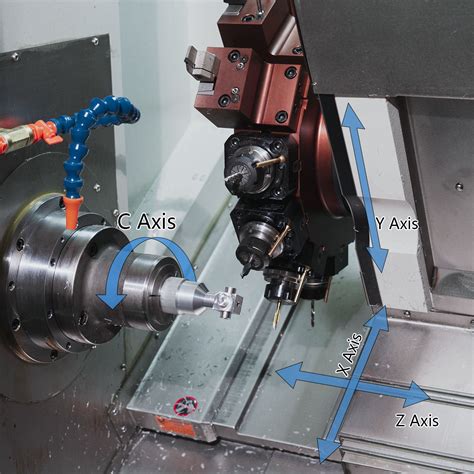

1 · lathe axis explained

2 · cnc xyz axis

3 · cnc machine axis locations diagram

4 · axis identification in cnc machine

5 · 7 axis robot arm cnc

6 · 7 axis machining center

7 · 7 axis cnc machine price

See current scrap price for Tin as of November 15, 2024. Check 30-day price chart for Tin and learn when to hold or sell your scrap metal. Price available for United States & Canada.

In simple terms, 7-axis CNC machines offer the ultimate capability for producing detailed and complex parts swiftly and accurately. Whether you’re in aerospace, automotive, or medical .

A 7 axis CNC machine is a computer-controlled machine tool that uses seven axes of motion to operate. This type of machine is capable of performing complex, multi-dimensional cuts and shapes with high precision .

y axis cnc lathe

lathe axis explained

7-axis CNC milling machines can create long, slender, and heavily detailed parts. The 7-axes involved are the usual right-left, top-down, and back-front, followed by the axes defined by the .Nexturn SA(B) Swiss CNC lathe series represent a cost efficient and productive 7-axis machine for complex precision parts. Three models feature synchronous guide bushings, 7 machining .L Dual “C” Axis and “Y” Axis with 19” Travel; L 27-Tools with 11-Driven Tools; L Simultaneous Main & Sub-Spindle CNC Swiss Machining; L Parts Catcher and Chip Conveyor Included; L 1,181 Inch per Minute Rapid RatesIn simple terms, 7-axis CNC machines offer the ultimate capability for producing detailed and complex parts swiftly and accurately. Whether you’re in aerospace, automotive, or medical manufacturing, these machines could revolutionize your production process, saving time and enhancing quality.

7 axis CNC machining centers have a confined workspace with limited capacity. They are suitable for machining small to medium-sized parts. Average-sized machining centers can fit parts with a volume up to 1-2 cubic feet at best. A 7 axis CNC machine is a computer-controlled machine tool that uses seven axes of motion to operate. This type of machine is capable of performing complex, multi-dimensional cuts and shapes with high precision and accuracy.7-axis CNC milling machines can create long, slender, and heavily detailed parts. The 7-axes involved are the usual right-left, top-down, and back-front, followed by the axes defined by the spinning of the tool, rotation of the part, rotation of the tool head, and movement for clamping, reclamping, or removing the part.Nexturn SA(B) Swiss CNC lathe series represent a cost efficient and productive 7-axis machine for complex precision parts. Three models feature synchronous guide bushings, 7 machining axes and as many as 22 tools to handle maximum bar diameters of 12mm, 20mm and 32mm.

L Dual “C” Axis and “Y” Axis with 19” Travel; L 27-Tools with 11-Driven Tools; L Simultaneous Main & Sub-Spindle CNC Swiss Machining; L Parts Catcher and Chip Conveyor Included; L 1,181 Inch per Minute Rapid Rates7-axis CNC machining offers unprecedented precision, flexibility, and efficiency for producing complex parts. Here's how this advanced technology is being applied in several key industries: In the aerospace industry, 7-axis CNC machining plays a crucial role in manufacturing highly complex components with extreme precision.7-axis Citizen L12VII is the perfect machine for your small diameter machining needs. With 15,000 RPM main spindle speeds, this dynamo has a true need for speed! Learn more about the Citizen L12VII.

The i-42 Twin /i-60 Twin features 7 axes, 2 turning spindles, 1 milling spindle, 1 B-axis, and a total capacity of 30 tools. A 4-axis (X,Y,Z,B) gang type vertical tool post is shared between each C axis spindle. The main spindle sports a 15 HP high torque spindle motor. Aerospace CNC machining involves removing material precisely to get the desired shape – which is accurate down to the last atom. This is done across three, four, five, or seven axes, which ultimately determines the type of work needed.In simple terms, 7-axis CNC machines offer the ultimate capability for producing detailed and complex parts swiftly and accurately. Whether you’re in aerospace, automotive, or medical manufacturing, these machines could revolutionize your production process, saving time and enhancing quality.

7 axis CNC machining centers have a confined workspace with limited capacity. They are suitable for machining small to medium-sized parts. Average-sized machining centers can fit parts with a volume up to 1-2 cubic feet at best. A 7 axis CNC machine is a computer-controlled machine tool that uses seven axes of motion to operate. This type of machine is capable of performing complex, multi-dimensional cuts and shapes with high precision and accuracy.7-axis CNC milling machines can create long, slender, and heavily detailed parts. The 7-axes involved are the usual right-left, top-down, and back-front, followed by the axes defined by the spinning of the tool, rotation of the part, rotation of the tool head, and movement for clamping, reclamping, or removing the part.Nexturn SA(B) Swiss CNC lathe series represent a cost efficient and productive 7-axis machine for complex precision parts. Three models feature synchronous guide bushings, 7 machining axes and as many as 22 tools to handle maximum bar diameters of 12mm, 20mm and 32mm.

cnc xyz axis

L Dual “C” Axis and “Y” Axis with 19” Travel; L 27-Tools with 11-Driven Tools; L Simultaneous Main & Sub-Spindle CNC Swiss Machining; L Parts Catcher and Chip Conveyor Included; L 1,181 Inch per Minute Rapid Rates7-axis CNC machining offers unprecedented precision, flexibility, and efficiency for producing complex parts. Here's how this advanced technology is being applied in several key industries: In the aerospace industry, 7-axis CNC machining plays a crucial role in manufacturing highly complex components with extreme precision.7-axis Citizen L12VII is the perfect machine for your small diameter machining needs. With 15,000 RPM main spindle speeds, this dynamo has a true need for speed! Learn more about the Citizen L12VII.The i-42 Twin /i-60 Twin features 7 axes, 2 turning spindles, 1 milling spindle, 1 B-axis, and a total capacity of 30 tools. A 4-axis (X,Y,Z,B) gang type vertical tool post is shared between each C axis spindle. The main spindle sports a 15 HP high torque spindle motor.

cnc machine axis locations diagram

axis identification in cnc machine

7 axis robot arm cnc

7 axis machining center

Fasteners that are commonly used on sheet metal include: clecos, rivets, and sheet metal screws. See more

cnc 7 axis machine|lathe axis explained