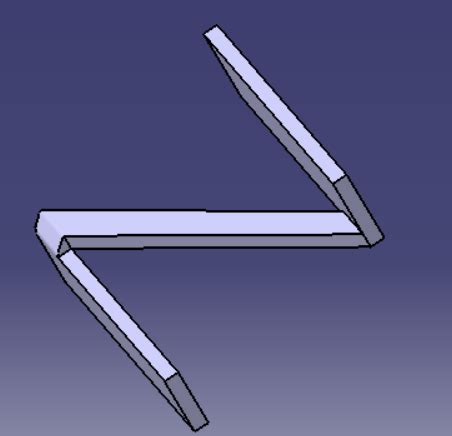

z bend sheet metal E-Z Bend Tubing Benders and Sheet Metal Brakes were introduced in 1997. Proudly built and designed in the U.S.A. as quality and affordable by Bill Schwader, who has a background in auto racing starting in 1959. He was a . CNC lathe is a powerful machine tool that is used to create high-quality shape materials by removing excess materials from the workpiece. However, you should get the best CNC Lathe types and parts to get the best .

0 · z shaped sheet bending

1 · z shaped metal sheet

2 · z shaped bending tools

3 · z bending sheet metal

4 · z bending machine

5 · sheet metal z bending process

6 · sheet metal bending properties

7 · how to bend sheet metal

With a Japanese car, I doubt any of the sections on the car are 1.2mm. That is classic car thickness, not modern car metal. 1.0mm sheet will be plenty! ;-) 1.2mm is easier to weld with 0.6mm wire if you weld to the edge of the thicker material and let it run onto the thinner.

z shaped sheet bending

schneider electric push button enclosure

z shaped metal sheet

This article dives into the essential techniques and precautions for Z and N bending in sheet metal fabrication. You’ll learn about critical .Z Bend Sheet Metal Mounts - 2 Slots, 2 Holes. MISUMI. For fixture mounting applications. • Type: SWBBS Shape: Z Bend, 2 Mounting Holes, 2 Slots Material: Low Carbon Steel, 5052 Aluminum Alloy, 304 Stainless SteelE-Z Bend Racer's Brake Avaliable in 6' or 6.5' • Rated Maximum: 20 Gauge Mild Steel • Bend Lexan up to 1/8" • Full Width Hems • Full Width 1/4" Lip • Bends Three Sides • Bend Sharp or Radius Bends. 6’ Racer’s Brake Shipping Weight .

E-Z Bend Tubing Benders and Sheet Metal Brakes were introduced in 1997. Proudly built and designed in the U.S.A. as quality and affordable by Bill Schwader, who has a background in auto racing starting in 1959. He was a .An overview of all WILA press brake products for offset bending (Z-bending). 443-459-5496 Find your local dealer EN-US NL . Bending sheet metal in different angles using a limited set of tools. Bottom bending Bending sheet metal by enclosing the sheet between the punch and the die. .Shop Z Bend Sheet Metal Mounts - 6 Holes from MISUMI. MISUMI USA has all of your Configurable Z-Plates needs covered, with over 3.8M high quality products and 80 sextillion configurable parts available with fast shipping and low pricing.

Shop Z Bend Sheet Metal Mounts - 2 Holes, 1 Hole from MISUMI. MISUMI USA has all of your Configurable Z-Plates needs covered, with over 3.8M high quality products and 80 sextillion configurable parts available with fast shipping and low pricing.Shop Z Bend Sheet Metal Mounts - 2 Slots, 1 Hole from MISUMI. MISUMI USA has all of your Configurable Z-Plates needs covered, with over 3.8M high quality products and 80 sextillion configurable parts available with fast shipping and low pricing.

screens and fabricated metals

How to make a simple Z Flash using a metal brake. This flashing is used above windows and other horizontal trim to prevent water intrusion.The thicker or more brittle the material is the larger the radius of the bend will be. Also ask them if they use a k-factor to calculate the bend deductions or if they just have the bend deduction values for you. Radius and bend deduction numbers can be entered into the sheet metal feature in Solidworks so your flat patterns actually work out. Z-bend, also known as offset bending, refers to bending in the opposite direction. The angle is divided based on the difference between the hypotenuse and straight edge. The minimum size of the bending process is limited by the mold, and the maximum size is determined by the processing machine’s shape.Galvanized Steel Z-Flashing is made from 28-Gauge galvanized steel. It is used to protect the horizontal joints between sheets of siding from water infiltration. The large leg of the metal goes against the wall, leaving the seat and face covering the top edge of the siding. The seat dimension, 1 in., corresponds to the siding thickness.

So far the best solution I have found is to take the flat pattern, copy it to a sketch, build a new sheet metal base from the sketch, cut away the old sheet metal base, and then redraw all of the sketched bend on the new sheet metal piece. This is very inelegant and frustrating way of going about a relatively simple task.Choose from our selection of sheet metal pliers, including over 325 products in a wide range of styles and sizes. In stock and ready to ship. BROWSE CATALOG. Abrading & Polishing; . Bend. Straight. Jaw Opening Style. Manual. Spring Assisted. For Maximum Steel Thickness. 0.015" 1/64" 0.02" 1/32" 3/64" 1/16" 1/8" 9/64" 3/16" Forward.The E-Z Bend Racer's Brake's reversible bend bar features an inverted "V" edge on one side for sharp bends and folds and a rounded edge on the other side for perfect radius bends. The bend bar applies constant pressure across the surface to prevent material slippage. No serious racer’s shop is complete without the E-Z Bend Racer’s Brake.

How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----.

bend down the end flaps, [4] and [5] using the brake. bend the end flaps [4] and [5] back up again using the brake so the cutout is flat again, this will leave a strong crease. Do a Z-bend on the brake to make the bends for [1], [2] and [3] .

Shop Z Bend Sheet Metal Mounts - 4 Holes from MISUMI. MISUMI USA has all of your Configurable Z-Plates needs covered, with over 3.8M high quality products and 80 sextillion configurable parts available with fast shipping and low pricing.

The Z bend needs to have it's own bend deduction values so that your flat pattern is accurate. It alsp needs to have its own design rules that define the available offsets and their resultant bend radii . A sheet metal offset is different than a flange and is not a special process. If Inventor can product a flat pattern it needs to have the .

I have a sheet metal part, and would like to add a bend somewhere in the middle of an existing flat area. I can find how to add a bend by adding material on a free edge, but no way to bend a flat zone along a given line without adding material. The bending line could be defined by a segment in a sketch drawn on the face. Someone can help please? Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. When the sheet metal bend is aligned with the direction of the metal fibers, it is more likely to crack at the bend and have low bending strength, making it prone to breaking, as depicted in the accompanying figure. .Shop Z Bend Sheet Metal Mounts - 2 Slots, 4 Holes from MISUMI. MISUMI USA has all of your Configurable Z-Plates needs covered, with over 3.8M high quality products and 80 sextillion configurable parts available with fast shipping and low pricing. a) V-bend; b) U-bend; c) Z-bend; Related: V & U-shaped Bend Force Calculator (2) Press Bake Bending. Press brake bending is commonly used for the processing of sheet metal bending parts that are larger in size or not produced in large quantities. Press brakes can be divided into ordinary press brake and CNC press brake.. For sheet metal bending parts with .

If you’re utilizing 3D CAD software, d raw the part with the flanges in place using the sheet metal function in whatever CAD software you are using. Once you have the flanges in place, edit the bend radius to match the advanced details found at the bottom of the bending calculator. . The K-factor in sheet metal bending represents the ratio .

Instruction . This article introduces the how to use Press Brake to bend shapes in sheet metal, mainly motheds are Z-bending, N-bending, O-bending,U-bending,L-bending. By the following knowledge you can know more about different shapes of bending, and their bending techniques and technical details, etc., which will benefit your sheet metal work.Find z flashing at Lowe's today. Shop z flashing and a variety of building supplies products online at Lowes.com. The offset process in sheet metal is bending a sheet metal workpiece in an equipment unit or offset bender. Bend the metal by 20° to 30° using the formers. Release the part, turn it over, and joggle sheet metal to bend it again. Repeat till the correct height of the section or the joggle in sheet metal is achieved.

#2 Type of Bend Required. Different bends (sharp, gradual, complex shapes) require different techniques and tools. Sharp bends might need stronger tools like press brakes, while gradual bends can be achieved with rollers.

A junction box – also known as an ‘electrical box’, ‘jbox’, ‘or ‘terminal box’ – is a protective box where wires are interconnected. Junction boxes are often built into the plaster of a wall, in the ceiling, or within concrete.

z bend sheet metal|z shaped sheet bending