adaptive control in cnc machine ppt The adaptive control is basically a feedback system that treats the CNC as an . Those vintage models are worth some ridiculous coin today. How much? Well, these are the most valuable lunch boxes out there. And they will set you back more than the cost of a couple of Happy Meals. 17. Lone Ranger ‘Red Band’ Maker: Adco Liberty. Year: 1955. Approximate Value: $1,250. Bottom Line: Lone Ranger 'Red Band' Who didn’t love .

0 · adaptive control system

1 · adaptive control ppt

Beads can be made up of metal, fabric, wood (including bamboo), shells, gems, and so on. Wooden beads or just beads that have larger holes, making them ideal to decorate dreadlocks. You just have to look for the perfect fit and slide them on.5" Stainless Steel Floating House Number, Metal Modern House Numbers, Garden Door Mailbox Decor Number with Nail Kit, Coated Black, 911 Visibility Signage (1)

The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual .The document discusses computer numerical control (CNC), direct .The adaptive control is basically a feedback system that treats the CNC as an . The document discusses computer numerical control (CNC), direct numerical control (DNC), and adaptive control systems. It describes how CNC replaced conventional NC by using a computer to store machining programs .

The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process.This document discusses adaptive control systems for machining. Adaptive control systems automatically select process control variables based on measurements to overcome limitations of CNC systems. An adaptive .

Adaptive control systems aim to improve production rates and part quality in machine tools by optimizing machining variables in real-time. Sensors continuously monitor process parameters like tool temperature, cutting forces, .Adaptive control systems originated from research in the 1960s to optimize machining processes. They measure process variables like force, temperature, and vibration and adjust speed or feed rates in real-time.

metal gear solid 3 box d in groznyj grad

The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process. The proper .

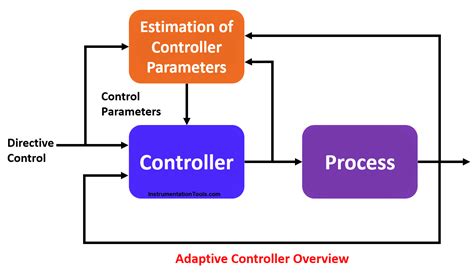

• “Adaptive Control” techniques provide a systematic approach for automatic on-line tuning of controller parameters • “Adaptive Control” techniques can be viewed as approximations of .Adaptive Control, a thirty-year old eld, is an advanced control method that is becoming increasingly popular in various engineering applications. The ability to self-correct a controller . The paper discussed basic classes of adaptive control: adaptive control with optimization (ACO), adaptive control with constraints (ACC), and geometric adaptive control (GAC), as well as.

The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process. This document .

The document discusses computer numerical control (CNC), direct numerical control (DNC), and adaptive control systems. It describes how CNC replaced conventional NC by using a computer to store machining programs instead of punched tapes. The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process.This document discusses adaptive control systems for machining. Adaptive control systems automatically select process control variables based on measurements to overcome limitations of CNC systems. An adaptive controller makes feed rate and speed corrections based on measured variables from sensors.

Adaptive control systems aim to improve production rates and part quality in machine tools by optimizing machining variables in real-time. Sensors continuously monitor process parameters like tool temperature, cutting forces, spindle torque, and vibration.Adaptive control systems originated from research in the 1960s to optimize machining processes. They measure process variables like force, temperature, and vibration and adjust speed or feed rates in real-time. The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process. The proper implementation and role of flexible manufacturing system in current scenario.

• “Adaptive Control” techniques provide a systematic approach for automatic on-line tuning of controller parameters • “Adaptive Control” techniques can be viewed as approximations of some nonlinear stochastic control problems (not solvable in practice) • Objective of “Adaptive Control” : to achieve and to maintain

Adaptive Control, a thirty-year old eld, is an advanced control method that is becoming increasingly popular in various engineering applications. The ability to self-correct a controller in the presence of uncertainties using online information is its main and most compelling feature. The paper discussed basic classes of adaptive control: adaptive control with optimization (ACO), adaptive control with constraints (ACC), and geometric adaptive control (GAC), as well as.

The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process. This document . The document discusses computer numerical control (CNC), direct numerical control (DNC), and adaptive control systems. It describes how CNC replaced conventional NC by using a computer to store machining programs instead of punched tapes.

The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process.This document discusses adaptive control systems for machining. Adaptive control systems automatically select process control variables based on measurements to overcome limitations of CNC systems. An adaptive controller makes feed rate and speed corrections based on measured variables from sensors.

adaptive control system

Adaptive control systems aim to improve production rates and part quality in machine tools by optimizing machining variables in real-time. Sensors continuously monitor process parameters like tool temperature, cutting forces, spindle torque, and vibration.Adaptive control systems originated from research in the 1960s to optimize machining processes. They measure process variables like force, temperature, and vibration and adjust speed or feed rates in real-time. The adaptive control is basically a feedback system that treats the CNC as an internal unit and in which the machining variables automatically adapt themselves to the actual conditions of the machining process. The proper implementation and role of flexible manufacturing system in current scenario.• “Adaptive Control” techniques provide a systematic approach for automatic on-line tuning of controller parameters • “Adaptive Control” techniques can be viewed as approximations of some nonlinear stochastic control problems (not solvable in practice) • Objective of “Adaptive Control” : to achieve and to maintain

metal gear solid the phantom pain box art

Adaptive Control, a thirty-year old eld, is an advanced control method that is becoming increasingly popular in various engineering applications. The ability to self-correct a controller in the presence of uncertainties using online information is its main and most compelling feature.

adaptive control ppt

4-drawer file cabinet holds letter, legal and A-4 file sizes. WorkPro 42"W steel lateral file cabinet includes hang rails. Stylish WorkPro steel file cabinet comes in charcoal. GREENGUARD certified — certified for low chemical emissions: UL.COM/GG - UL .

adaptive control in cnc machine ppt|adaptive control system