design sheet metal box Metal Box Design Software. Design and customize a sheet metal box in minutes using eMachineShop’s metal box design wizard. 100k+ CAD . CNC milling stands as a pivotal process in modern manufacturing, offering precision and repeatability essential for complex parts. Converging computerized technology with mechanical cutting operations, it ensures meticulous control over production.

0 · simple sheet metal projects

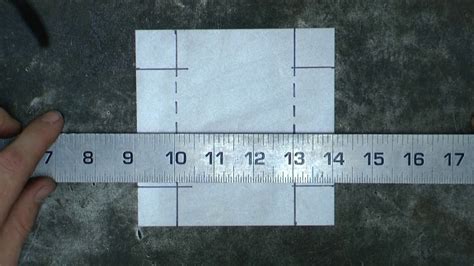

1 · sheet metal box layout

2 · sheet metal box fabrication

3 · sheet metal box drawing

4 · sheet metal box design template

5 · sheet metal box design guide

6 · free sheet metal project plans

7 · cool small sheet metal projects

Sheet metal blanking results in blanks with imperfections of rough edges called burrs which affect part quality, functionality and are unsafe. Deburring enables you to remove .

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my .A Riveted Metal Box With Lid: This is a practice box, so it's not very nice . Metal Box Design Software. Design and customize a sheet metal box in minutes using eMachineShop’s metal box design wizard. 100k+ CAD .

Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs. Fabricating a sheet metal box can seem daunting, but with the right tools and techniques, it can be a straightforward process. In this article, we’ll go over the steps to fabricate a sheet metal box, including cutting, bending, .A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal . Mastering sheet metal enclosure design requires careful consideration of functional requirements, material selection, shape, thickness, tolerances, bend radii, and finishing options.

Fabricating a sheet metal box can be a rewarding DIY project or a valuable skill for professionals. In this comprehensive guide, we'll walk you through the step-by-step process of creating a .

simple sheet metal projects

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables.Metal Box Design Software. Design and customize a sheet metal box in minutes using eMachineShop’s metal box design wizard. 100k+ CAD Users. 25+ Part Templates and Shapes.Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs. Fabricating a sheet metal box can seem daunting, but with the right tools and techniques, it can be a straightforward process. In this article, we’ll go over the steps to fabricate a sheet metal box, including cutting, bending, and welding. Step 1: Designing the Box. Before you start fabricating your sheet metal box, you’ll need to design it.

A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on.

sheet metal box layout

Mastering sheet metal enclosure design requires careful consideration of functional requirements, material selection, shape, thickness, tolerances, bend radii, and finishing options.Fabricating a sheet metal box can be a rewarding DIY project or a valuable skill for professionals. In this comprehensive guide, we'll walk you through the step-by-step process of creating a sheet metal box, ensuring you have all the information you need to succeed.

In this step-by-step guide, we will delve into the world of custom sheet metal boxes, exploring their significance, applications, and the precise craftsmanship required to create them. A crucial aspect of fabricating custom sheet metal boxes is comprehending the unique requirements of .

Regarding manufacturing and designing products, the box design in sheet metals significantly impacts various applications, such as industrial components and consumer goods. Sheet metal boxes are a versatile and essential component in various industries, ranging from automotive to electronics. This comprehensive guide will delve into the fundamentals of sheet metal boxes, their applications, and the intricacies involved in .

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables.Metal Box Design Software. Design and customize a sheet metal box in minutes using eMachineShop’s metal box design wizard. 100k+ CAD Users. 25+ Part Templates and Shapes.Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs.

best metal fabrication books

Fabricating a sheet metal box can seem daunting, but with the right tools and techniques, it can be a straightforward process. In this article, we’ll go over the steps to fabricate a sheet metal box, including cutting, bending, and welding. Step 1: Designing the Box. Before you start fabricating your sheet metal box, you’ll need to design it.A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on.

Mastering sheet metal enclosure design requires careful consideration of functional requirements, material selection, shape, thickness, tolerances, bend radii, and finishing options.Fabricating a sheet metal box can be a rewarding DIY project or a valuable skill for professionals. In this comprehensive guide, we'll walk you through the step-by-step process of creating a sheet metal box, ensuring you have all the information you need to succeed. In this step-by-step guide, we will delve into the world of custom sheet metal boxes, exploring their significance, applications, and the precise craftsmanship required to create them. A crucial aspect of fabricating custom sheet metal boxes is comprehending the unique requirements of .

Regarding manufacturing and designing products, the box design in sheet metals significantly impacts various applications, such as industrial components and consumer goods.

best locks for steel storage cabinets

sheet metal box fabrication

At its core, a CNC machine is a computer-controlled device that automates the operation of machine tools, such as mills, lathes, routers, and grinders. Unlike conventional manual machines, where operators physically manipulate tools, .

design sheet metal box|sheet metal box layout