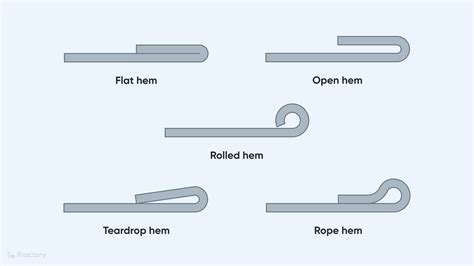

folded edge sheet metal In Sheet Metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. Hems are most often used to remove a sharp untreated edge and make it safe for handling.

A junction box contains two 3-in. raceways on the left side, one 3-in. raceway on the right side, and one 3-in. raceway on the bottom. The conductors from the lower 3-in. raceway on the left wall are pulled through the .

0 · sheet metal teardrop hem

1 · sheet metal side seam

2 · sheet metal seam

3 · sheet metal hemming

4 · sheet metal heming angle

5 · sheet metal folding machine

6 · sheet metal flat hems

7 · sheet metal die hemming

Coolants can be broadly classified into several categories, each with distinct properties and applications: 1. Water-Based Coolants. Example: A water-based coolant containing rust inhibitors and biocides is used for milling aluminum parts on .

Sheet metal hem is a fabrication process where the edge of sheet metal is folded over onto itself, creating a smooth, rounded finish that enhances the final product’s safety and aesthetic appeal. This post will take you through the .There are numerous types of edges, joints, seams, and notches used to join sheet-metal work. We will discuss those that are most often used. Edges. Edges are formed to enhance the .Mastering the basics of sheet metal folding is essential for achieving high-quality, precise, and efficient results in your projects. You can enhance your manufacturing process by . Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.

Hemming in sheet metal fabrication refers to the process of folding a piece of metal over onto itself to conceal an edge or burr, provide added strength, or achieve a smooth aesthetic appearance. What are the four most .In Sheet Metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. Hems are most often used to remove a sharp untreated edge and make it safe for handling.

Sheet metal hemming is a metal-forming technology that involves rolling or folding sheet metal edges over and onto itself. You have to fold over the edges of sheet metal to create an area with two layers. Hemming reinforces the sheet metal by folding its edges, which doubles the material thickness at the critical points. This not only increases the strength and durability of the metal but also reduces the risk of deformation .Sheet Metal folding is part of the forming stage within metal sheet fabrication, and can be a complex process. Find out more information here. Need help? Call us today on 01904 737095 or email the team directly at: .

what Edge is used to cover nail heads and edges of sheet metal? a blind Edge. what ham is a folded Edge used to increase the strength and make a smooth finished edge? a single hem. true or false, a brake should be bolted to the floor to prevent movement?Sheet Metal Folding Tool: Hurricane 24" sheet metal folding tools offer a premium choice for bending and forming metal, folding seams are formed from two steel halves, permanently joined together ; . Sheet Metal Seamer Form Edge .

Sheet Metal Hemming vs Seaming. As we mentioned above, sheet metal hemming is a process of folding the edge of a single metal sheet back onto itself to create a clean, finished edge. This is typically done by bending the metal over a die or roller, resulting in a 180-degree fold or a tighter, more acute angle.Study with Quizlet and memorize flashcards containing terms like When creating a sheet metal____, create the profile in that shape from the start., Base Flange, Bend Allowance Options and more. . Used to add a flange along an edge, or multiple edges of your Sheet Metal part. . Used to fold over an edge of a Sheet Metal part. About us. About . Kwando Technic introduce How to Homemade A Metal Pressing Tool.#sheetmetal; #foldmetal; #pressingtool; #kwandotechnicPlease like, share and subscribe my chan.

The world of metal folding encompasses a vast array of techniques, each designed for specific applications. Common techniques include: Hemming: Creating a folded edge to reinforce or conceal raw edges. Flanging: Bending a flange along the edge of a sheet to provide strength or support.Here is a nice video showing how to unfold a sheet metal part commonly known as flat pattern in Solid Edge. Solid Edge Solid Edge Knowledge Base Filter Feed Refresh this feed With hemming, the edge of sheet metal is folded so that it becomes flush with the area onto which it’s rolled. With seaming, the edge of sheet metal is folded but it doesn’t sit flush. Rather, the two layers of the folded sheet metal are joined using a seam. You’ll often find seams on metal roofs. The edges of metal roofs are folded and .

This short episode of Metal Magic provides some quick tips on the most effective ways to get sheetmetal to "lay down" properly. KITPLANES editor at large Pau.Yes, correct. When you subtract a body from another body, the body you subtract is removed (That's just how SW is set up). You can use the move/copy feature with the copy option and no transforms to retain a second copy of the body for your drawing/modeling use. Hems, created by folding the edge of the sheet metal, increase edge strength and improve safety by eliminating sharp edges. Both open hems, which provide additional clearance, and closed hems, which completely encase the edge, . Sheet Metal Unfolding Calculation Guide – How To Unfold Sheet Metal Step By Step. 1. Unfold at right angles . As shown in the figure, this box has a length of 200, a width of 100, a height of 80, and a folded edge of 10. Therefore, bending requires 8 cuts, which is 4 cuts each from 10 to 80. Let’s first make a copy of the main view:

In this video I show you how to make a return lip on a panel so you can get a nice clean non sharp edge without expensive toolsIf you would like to support m.

Sheet Metal Edge Finishing ToolSix pairs of cascade stacked rolls, allows to finish the sharp edge of sheet metal without breaking it.Tool capable to work on. This video discusses the different commonly used connection joints found on Sheet Metal Duct work.

Hemming is nothing but to fold the metal back on itself. In Sheet Metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. Hems are most often used to remove a sharp untreated edge .Folding – or bending – is one of the main processing methods for steel and sheet metal, and it requires utmost precision across all process steps. In this swarf-free sheet metal forming method, the material is shaped by exerting mechanical forceAmazon.com: folding tool sheet metal. . Sheet Metal Seamer Form Edge Seamer Seaming Plier with Ergonomic Handle, for Bending and Flattening Sheet Metal Hand Tool. 4.5 out of 5 stars. 92. 300+ bought in past month. .99 $ 20. 99. FREE delivery Wed, Nov 20 .

sheet metal teardrop hem

The next stop on our tour of the sheet metal functions in Solid Edge is the Hem tool. Hem is just meant to fold over the edges of parts usually for safety, aesthetic, or strength issues. .-Unfold the sheet by pulling it away from an edge of the sheet. -Fold up one side of the sheet and unfold another side. -Unfold a single layer at a time or all layers at once. Flatten Sheet Metal Surfaces in SolidWorks SolidWorks is a CAD software that allows users to create 3D models of their designs. . Fold sheet metal is an excellent . When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Tab - Add a tab to a sheet metal flange.; Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) .

Edge Flanges: Miter Flanges: Swept Flange: Hems: Sketched Bends: Closed Corners: Flattening Sheet Metal Bends: No Bends: Jogs: . The Welded Corner PropertyManager allows you to add a weld bead to the corners of a folded sheet metal part, including miter flanges, edge flanges, and closed corners. Parent topicUsing Sheet Metal Tools.

Edge Treatment. Sheet metal projects often require edge treatment: For decorative purposes; To make edges stronger; To make edges safe to handle. Common edge treatments used in basic sheet metalwork are: The folded edge; The double folded edge; The wired edge. These edge treatments are shown in the pictorial sketches and pattern developments on .Without sheet metal folding, your product would never take the right shape. 4. What is the sheet metal folding process? Now you know how to fold sheet metal, let’s go through the sheet metal folding process in more detail. Sheet metal folding is a complex process and requires plenty of knowledge and experience to complete both safely and .This technique, also called edge bending, would push the sheet metal against the edge of the die, bending it to the angle that you need. The flange is held and controlled by an upper shoe and the die is supported by a lower shoe. . These metal folding techniques have their niches in the metal fabrication industry. If you want to focus on .6,596 folded edge metal stock photos, vectors, and illustrations are available royalty-free for download. . Metal sheet, folded paper pattern. Perspective lines make a modern, elegant banner for business, website, flyer. blue and black textured backdrop. Save. Abstract background, closeup mustard yellow texture. Metal sheet, folded paper .

cnc machine 5 axis price

cnc leather knife cutting machine

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

folded edge sheet metal|sheet metal folding machine