what is axis in cnc machine CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth). A utility box, sometimes referred to as an electrical box, is an essential component in electrical systems. Not only does it protect wires and devices from damage, but it also reduces the risk of electrical shocks.

0 · cnc with rotary axis

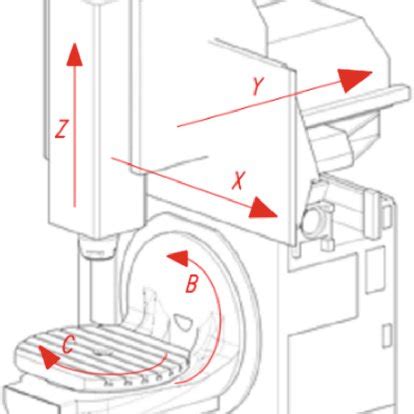

1 · cnc machine axis locations diagram

2 · cnc machine axis direction

3 · cnc axis explained

4 · cnc axis chart

5 · axis identification in cnc machine

6 · 4 axis cnc milling machines

7 · 4 axis cnc machine cost

Heavy Duty 4” Slide Gate V-Groove Wheel Dual Bearing Bolted External Mount Bracket Cradle Solid Steel for Inverted V-Shape Sliding Rolling Track Gates up to 3000lbs Capacity – NO Welding

CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

Axes of a CNC milling machine. Taking the most common vertical CNC mills as an example, 3 axes control the linear motion of the workpiece and the spindle, the X axis moves left and right, the Y axis moves forward and . 6 axis CNC: A 6 axis CNC machine is a type of CNC machine that can move and rotate its cutting tool or workpiece in six different directions. It can perform complex and precise operations that are impossible or difficult with .

A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. More specifically, it can move .

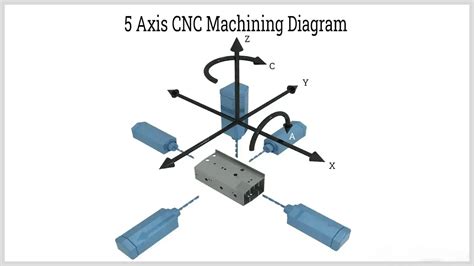

A 5 axis CNC mill is a cutting-edge machine that can move in five different directions, allowing for more complex and intricate cuts compared to traditional 3 axis or 4 axis mills. This advanced technology enables the tool to approach . The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two . 4-axis CNC machining allows for greater precision and versatility in the production of complex parts. The fourth axis, also known as the A-axis, enables the machine to rotate the part being worked on, allowing for more .

4 axis machining implies that a workpiece is processed in the same way it would be with a 3 axis machine, but has an additional rotary movement around the X axis, which is named the A axis. This rotation allows the workpiece to be cut . A 5-axis CNC machine is a sophisticated tool that allows for the creation of complex parts with high precision and flexibility. Its ability to move in five different directions means it can .Typical CNC tools support translation in 3 axis; multiaxis machines also support rotation around one or multiple axis. 5-axis machines are commonly used in industry in which the workpiece is translated linearly along three axes (typically x, y, and z) and the tooling spindle is capable of rotation about an addition 2 axes.

What is 5-Axis CNC Machining? In 5-axis CNC machining, the term “5-axis” refers to the number of directions in which the cutting tool or workpiece can move.The 5-axis on a CNC machine include three primary linear axes (X, Y, Z) and two rotary axes, often referred to as 5th axis or cnc a axis.. X, Y, Z Axes: These represent the traditional three dimensions of space, . 3-Axis CNC machines utilize X, Y, and Z axes to perform precise movements in three-dimensional space, making them ideal for flat surfaces and simple geometries. 4-Axis CNC machines introduce an additional rotational axis (A-axis) that enables the machine to rotate the workpiece, unlocking capabilities for indexing and contouring operations. 5 . CHAPTER 1: Introduction to 4 Axis CNC. 4th Axis machining is an interesting and important sub-part of the CNC milling world. Haas actually got it’s start building a 4th axis before it ever built entire CNC machines (pictured on the right). This is an article series to help beginners understand how and why a 4th Axis is used on CNC Mills. A 7 Axis CNC machine is a type of computer numerical control machine that has seven axes of motion. It is capable of performing complex and precise machining operations on a variety of materials such as metals, plastics, and composites. The additional axes of motion allow for greater flexibility and accuracy in the machining process, making it .

5-axis CNC machines are commonly used in industries requiring complex and precision machining, such as aerospace, automotive, medical, mold and stone fabrication. These machines are ideal for producing parts with intricate designs, curved surfaces, and tight tolerances. Some common applications of 5-axis CNC machines include: 3 axis CNC machines: The simplest and cheapest type.Good for cutting flat 2D and 2.5D parts. 4 axis CNC machines: More flexible and accurate.Can drill on sides and cylindrical surfaces. 5 axis CNC machines: The most advanced and expensive type.Can produce complex 3D shapes and angled features.

cnc with rotary axis

The flexibility and capabilities of 5-axis CNC machines make them essential tools in industries such as aerospace, automotive, and medical. Applications Of 5 Axis CNC Machining . 5-axis CNC machining has become a crucial technology across various industries, offering unmatched precision and versatility for complex manufacturing tasks. Understanding 5-axis machining is less simple, though. To help, we are breaking down each of the five axes below. What are the three basic axes? Standard 3-axis milling takes place on the X-, Y-, and Z-axes. These three linear axes are the directions the spindle or part—depending on the machine—can move: X-axis: Left-to-right; Y-axis . The future of 5-axis CNC machining includes enabling accurate automation, not only for mass production, but also down to a lot size of one. To obtain a highly accurate, low-volume of high-value parts via an automated 5-axis system, it is vital that the CNC be connected to a reliable, repeatable, and accurate motion system. . A 4-axis machine that cannot link the fourth axis is termed the 3+1 axis or fake 4-axis, and a 5-axis machine unable to link the fourth and fifth axis is called a 3+2 axis or fake 5-axis. During processing, a 3+1 CNC milling machine needs to rotate the fourth axis to a specific position and then fix it in place for part processing.

breath of the wild metal box respawn

7-axis CNC machining offers much better benefits than 5-axis CNC machining, such as increased precision, accuracy, time, and cost savings with the added advantage of increased versatility. It enables manufacturers to create complex parts with intricate details in a single setup, eliminating any need for manual reorientation or additional setups Four-axis CNC machines may cut along all four axes at the same time or along the x, y and z axes simultaneously and around the vertical axis separately. These two designs for four-axis machines could affect production .

The C-axis can also be synchronized with the X and Z axes to facilitate multi-axis machining, further expanding the capabilities of the CNC lathe. In addition to these primary axes, CNC lathes may also have secondary axes .

breaker box vs electrical panel

cnc machine axis locations diagram

What Is 4-Axis CNC Machining? 4-axis machining is a type of CNC (computer numerical control) machining that uses four axes of motion to create parts and products. The X, Y, and Z axes are the three linear or conventional .A 9-axis CNC machine offers improved accuracy over a 7-axis machine by requiring fewer tool and workpiece movements than machines with fewer axes. The additional axes provide greater flexibility and control over the machining process, which can be useful in applications where very complex surfaces and extreme undercuts are required. It is a CNC machine. That's why I asked if you asked him what kind of machine. There are lathes out there at 8 axis, so I assume a custom built machine could exist with that many axis' Or his definition of what constitutes an axis could be a little "off"

Multi axis CNC machining. NC milling is a process that utilizes rotary cutters to remove materials. The workpiece can either remain stationary while the tool moves onto it or enter the machine tool at a predetermined angle. The complexity and speed of the forming process depend on the number of moving axes the machine has. The more axes a .

A 4-axis CNC mill offers increased flexibility and precision in machining operations. With the ability to rotate around the X-axis, the machine can create more intricate designs and produce parts with complex geometries. This makes it ideal for aerospace, automotive, and medical industries, where precision and intricate detailing are crucial.The 4-axis CNC mill also reduces the need for . The W axis is an additional axis on a CNC lathe machine that controls the movement of the secondary spindle. It is a linear axis that runs along the same line as the Z axis, but it is offset. The W axis is used to move the secondary spindle towards or away from the primary spindle. It controls the position of the workpiece, allowing for the .Each of the 5-axis machine styles is suited to a specific type of work. We discuss the vertical 5-axis vs horizontal 5-axis debate. Contact; Support +44 (0) 23 9258 0371. . 6-Axis Milling 6-axis machines use a unique 3-axis milling head to allow simultaneous 6-axis CNC machining that cuts production times by as much as 75%.

4-axis CNC machining comes with a slew of benefits that increase efficiency and provide cost-effective solutions for various manufacturing industries. Here are a few significant advantages: Enhanced Capabilities: The additional A-axis allows for the creation of more complex parts that would be difficult to achieve with three axes. This opens up .

A 3-axis CNC machine is the most basic type of CNC machine, moving the tool or part along three primary axes: X, Y, and Z. This type of machining is commonly used for simple and flat geometries. Understanding Each Axis and How It WorksA 5-axis CNC machine is a sophisticated manufacturing tool capable of simultaneously moving a cutting tool or workpiece along five distinct axes of motion. Unlike traditional 3-axis machines, which can only move in three directions (X, Y, and Z), a 5-axis CNC machine adds two rotational axes allowing for complex machining operations with .

CNC Machining ABOUT PRACTICAL MACHINIST With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals.

cnc machine axis direction

We use a multitude of these hangers everyday. We use them for joists, trusses, beams, headers, posts, columns and walls. A great resource for helping you select the proper connector is Simpson Strong-Tie .

what is axis in cnc machine|cnc with rotary axis