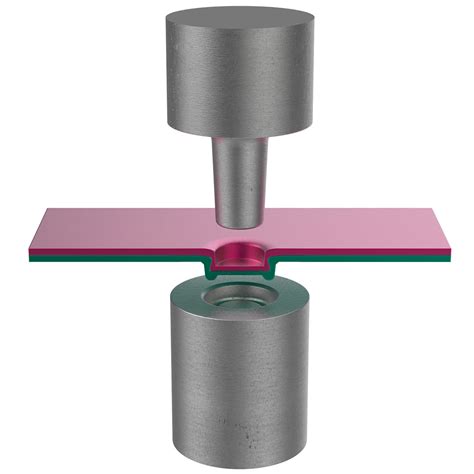

clinch lock sheet metal TOX®-Clinching is a simple joining technique that does not require heat or additional elements.The Clinching process produces a button-type, positive connection of two or three layers of sheet metal using a cold-forming process. It uses the solid die cavity patented by TOX® PRESSOTECHNIK.

In this article, we will explore the key differences between new work and old work electrical boxes, helping you make informed decisions for your electrical installations. Whether you’re a DIY enthusiast or a professional electrician, .

0 · tox clinching sheet metal

1 · tox clinching process

2 · tox clinching machine

3 · tox clinching

4 · norlok clinching

5 · clinching sheet metal

6 · clinching metal

Our automated Wheel Restore Machine delivers unparalleled quality repairs and the fastest turnaround times available. Automated painting, extraction, and curing. Eliminating guesswork or inconsistencies when painting wheels! The Diamond .

Clinching joins sheet metal by drawing and forming the part materials into an interlock. Using the part material improves production time and cost while eliminating welding and fasteners. It is .Lance-N-Loc® tooling joins hard metals (stainless) and metal to non-metal .

TOX®-Clinching is a simple joining technique that does not require heat or additional elements.The Clinching process produces a button-type, positive connection of two or three layers of sheet metal using a cold-forming .A Clinchlok joint is formed when the upper tooling squeezes the two ply of material joined between a punch and die. Clinching is a revolutionary way to join sheetmetal without traditional welding or fasteners. It’s cost-effective, reduces .Clinching joins sheet metal by drawing and forming the part materials into an interlock. Using the part material improves production time and cost while eliminating welding and fasteners. It is an environmentally-friendly process – no sparks, fumes or heat.TOX®-Clinching is a simple joining technique that does not require heat or additional elements.The Clinching process produces a button-type, positive connection of two or three layers of sheet metal using a cold-forming process. It uses the solid die cavity patented by TOX® PRESSOTECHNIK.

tox clinching sheet metal

A Clinchlok joint is formed when the upper tooling squeezes the two ply of material joined between a punch and die. Clinching is a revolutionary way to join sheetmetal without traditional welding or fasteners. It’s cost-effective, reduces production time, and minimizes thermal distortion.

best camera to monitor cnc machine

Lance-N-Loc® tooling joins hard metals (stainless) and metal to non-metal materials (gaskets, filter cloths), thick to thin and multiple layer combinations. Part geometry locked in a single joint (Geo-Clinch®).Factory List Price: ,790.00 USD. SL stands for “Sure Lok” and that’s what this Clinching machine makes: a permanent clinch lock of two pieces of metal. For a Duct Fab shop, the uses are numerous—Square to Rounds, Various Fittings, Flexible Duct Connectors and Drain Pans.

TOX® sheet metal clinching tools join two or more layers of sheet metal to replace rivets and welds. Click here to view clinching our riveting tools today!Clinching is the processes of joining sheet metal by drawing a circular button through two sheets, forming a mushroom shape, interlocking them together. The interlocking feature forms water tight, permanent, joints between them. Clinching provides a cleaner alternative to .Tog-L-Loc ® (pronounced tog-uhl-lŏk) is a process known as clinching which cold-forms the part metal using a special punch and die to form a strong interlocking clinch joint. The result of the process is a round, button shaped extrusion on the die side of the assembly, and a small cylindrical cavity on the punch side.

Find the right clinching joint for your sheet metal joining application. The TOX® clinch procedure is a proven substitute for welding, screwing & riveting.The best sheet metal clinching machines in North America. Pneumatic, hydraulic, floor-mounted, and handheld equipment. Shipping worldwide.Clinching joins sheet metal by drawing and forming the part materials into an interlock. Using the part material improves production time and cost while eliminating welding and fasteners. It is an environmentally-friendly process – no sparks, fumes or heat.TOX®-Clinching is a simple joining technique that does not require heat or additional elements.The Clinching process produces a button-type, positive connection of two or three layers of sheet metal using a cold-forming process. It uses the solid die cavity patented by TOX® PRESSOTECHNIK.

A Clinchlok joint is formed when the upper tooling squeezes the two ply of material joined between a punch and die. Clinching is a revolutionary way to join sheetmetal without traditional welding or fasteners. It’s cost-effective, reduces production time, and minimizes thermal distortion.Lance-N-Loc® tooling joins hard metals (stainless) and metal to non-metal materials (gaskets, filter cloths), thick to thin and multiple layer combinations. Part geometry locked in a single joint (Geo-Clinch®).Factory List Price: ,790.00 USD. SL stands for “Sure Lok” and that’s what this Clinching machine makes: a permanent clinch lock of two pieces of metal. For a Duct Fab shop, the uses are numerous—Square to Rounds, Various Fittings, Flexible Duct Connectors and Drain Pans.

TOX® sheet metal clinching tools join two or more layers of sheet metal to replace rivets and welds. Click here to view clinching our riveting tools today!Clinching is the processes of joining sheet metal by drawing a circular button through two sheets, forming a mushroom shape, interlocking them together. The interlocking feature forms water tight, permanent, joints between them. Clinching provides a cleaner alternative to .

Tog-L-Loc ® (pronounced tog-uhl-lŏk) is a process known as clinching which cold-forms the part metal using a special punch and die to form a strong interlocking clinch joint. The result of the process is a round, button shaped extrusion on the die side of the assembly, and a small cylindrical cavity on the punch side.Find the right clinching joint for your sheet metal joining application. The TOX® clinch procedure is a proven substitute for welding, screwing & riveting.

This lunch box features graphics on all sides, including the bottom and a message inside.There are a few dents in the corners and a few spots where the yellow boarders have scuffs where the paint is scratched. Hinge works well, handle is fully attached. Latch clasps tightly, but the lid seems to be bent slightly, visible when open.

clinch lock sheet metal|tox clinching