drawings cnc mechanical parts Fictiv is your operating system for custom mechanical parts, and we accept technical drawings and feature-specific tolerance requirements in a range of file formats. We can machine tolerances as tight as +/- 0.0002 and can provide finishing, hardware installation, and .

A typical 4-inch box is the right size, but the actual box dimensions, in particular, box depth and thus the space needed in cubic inches varies depending on how many wires or connectors will be in the box.

0 · technical drawings for cnc engineering

1 · manufacturing drawing notes

2 · engineering drawings for manufacturing

3 · engineering drawing for cnc manufacturing

4 · drawing for cnc parts

5 · cnc machining drawings

6 · cnc drawings

7 · cnc drawing process

There are many different sizes of purpose-built ceiling fan boxes out there, available even at your local hardware store. In addition to the standard round form factor, you may also find them in an octagon shape. Regardless of .

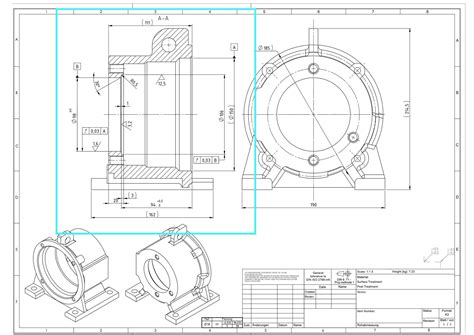

Generally, CNC machining drawings require different tools and methods to effectively create accurate diagrams, blueprints, and other visual representations of a mechanical design. Here are some of the essential .Fictiv is your operating system for custom mechanical parts, and we accept technical drawings and feature-specific tolerance requirements in a range of file formats. We can machine tolerances as tight as +/- 0.0002 and can provide . Technical drawing involves the use of various tools and techniques to accurately and precisely create diagrams, blueprints, and other visual representations of mechanical or architectural designs. Here, I will take . Generally, CNC machining drawings require different tools and methods to effectively create accurate diagrams, blueprints, and other visual representations of a mechanical design. Here are some of the essential components of a CNC technical drawing:

The technical drawing for CNC machining is composed of several essential components, including coordinates, title block, isometric view, orthographic views, section views, detail views, and pertinent notes for the manufacturer.Fictiv is your operating system for custom mechanical parts, and we accept technical drawings and feature-specific tolerance requirements in a range of file formats. We can machine tolerances as tight as +/- 0.0002 and can provide finishing, hardware installation, and .

Technical drawing involves the use of various tools and techniques to accurately and precisely create diagrams, blueprints, and other visual representations of mechanical or architectural designs. Here, I will take a brief look at some key components of technical drawings for CNC machining.

These part drawings and machining blueprints that are included as sets provide all the details with every dimension, tolerance, and specification needed for the production of parts with the highest level of accuracy. CNC machines rely on these technical drawings to produce highly accurate and precise parts. A technical drawing is a detailed illustration that shows every aspect of the part, including its size, shape, and dimensions. Technical drawings are the instructions that tell a CNC machinist how to make a part. They can be created using CAD software, or they can be hand-drawn. Once the technical drawing is complete, it is saved as a PDF and sent to the CNC machine . Creating accurate technical drawings for CNC machining requires precision, attention to detail, and manufacturing process knowledge. Here are some steps to follow: Create accurate technical drawings by extracting the dimensions, tolerances, and .

When it comes to CNC machining, technical drawings are essential instructions that shed light on 3D models. In this article, we discuss the components of technical drawings, their importance, and step-by-step instructions for preparing technical drawings for your parts.These are the essential parts of any technical drawing: It includes the fundamental details of the parts that must be manufactured, such as the part name, part number, firm name, specifications for the materials and finishing, drawing number, and much more. Generally, CNC machining drawings require different tools and methods to effectively create accurate diagrams, blueprints, and other visual representations of a mechanical design. Here are some of the essential components of a CNC technical drawing: The technical drawing for CNC machining is composed of several essential components, including coordinates, title block, isometric view, orthographic views, section views, detail views, and pertinent notes for the manufacturer.

Fictiv is your operating system for custom mechanical parts, and we accept technical drawings and feature-specific tolerance requirements in a range of file formats. We can machine tolerances as tight as +/- 0.0002 and can provide finishing, hardware installation, and .

Technical drawing involves the use of various tools and techniques to accurately and precisely create diagrams, blueprints, and other visual representations of mechanical or architectural designs. Here, I will take a brief look at some key components of technical drawings for CNC machining. These part drawings and machining blueprints that are included as sets provide all the details with every dimension, tolerance, and specification needed for the production of parts with the highest level of accuracy. CNC machines rely on these technical drawings to produce highly accurate and precise parts. A technical drawing is a detailed illustration that shows every aspect of the part, including its size, shape, and dimensions. Technical drawings are the instructions that tell a CNC machinist how to make a part. They can be created using CAD software, or they can be hand-drawn. Once the technical drawing is complete, it is saved as a PDF and sent to the CNC machine .

Creating accurate technical drawings for CNC machining requires precision, attention to detail, and manufacturing process knowledge. Here are some steps to follow: Create accurate technical drawings by extracting the dimensions, tolerances, and .When it comes to CNC machining, technical drawings are essential instructions that shed light on 3D models. In this article, we discuss the components of technical drawings, their importance, and step-by-step instructions for preparing technical drawings for your parts.

fire resistance rating of sheet metal

technical drawings for cnc engineering

manufacturing drawing notes

The vertical turning centers are used for heavy components, horizontal types are used widely for the general applications, so let’s explain 8 parts of a CNC lathe! 1. Headstock. The first part of CNC lathe is headstock which is located in the left side of the machine.

drawings cnc mechanical parts|engineering drawings for manufacturing