box beam header metal stud This video shows metal stud framing box beam header styles. Access the latest in construction video right here: https://goo.gl/wSSry6 Master Construction. B.

The supply is 3-wires: two blacks each going to a large breaker labeled for the cooktop and a stranded bare wire which connects to the panel ground. I'm reinstalling the same old cooktop from the 80's and it has 4 wires: black, red, white, and green.

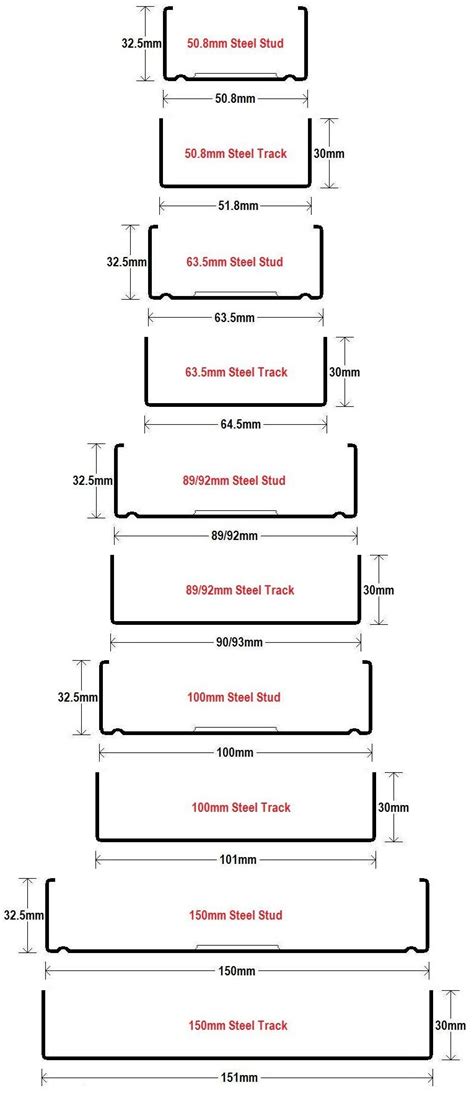

0 · metal stud size chart

1 · metal stud door header detail

2 · metal stud box header detail

3 · metal framing size chart

4 · metal box header span chart

5 · light gauge steel header chart

6 · exterior metal stud wall details

7 · exterior metal stud framing details

A junction box that is 4-by-4 inches with a 1-1/2-inch depth can hold up to 10 14-gauge or 9 12-gauge wires. What are the wires in a junction box? Junction boxes contain hot (black), neutral (white), and grounding (green or copper) wires.

There are two types of headers, L headers, and Box Headers. They discuss the advantages of each one starting on page 32. I like the attached file below for a table on how to size metal stud headers. See page 79 where . The Heavy-Duty Stud (HDS®) Framing System is a high .Boxed jamb studs welded together reduces material build-up and finish problems. Use of cripple stud to receive head/sill tracks at the jamb studs helps maintain alignment of finishes. Back to . This is a complete detailed instructional video on how to construct a metal stud box beam into a wall, complete with bottom header and layout. Access the lat.

The Steeler Technical Design Catalog is a collection of typical designs for steel framing and connections to help guide with your design process. The Calalog should only be used as a . This video shows metal stud framing box beam header styles. Access the latest in construction video right here: https://goo.gl/wSSry6 Master Construction. B.

This video will teach you how to build a box beam for metal stud framing. Learn metal stud framing RIGHT HERE: https://bit.ly/ExpertFramingLessons🚧 Best cla. In steel framing the primary header type used is a box header. The American Iron and Steel Institute did a great deep dive into box beam design and web stiffeners. There are two types of headers: L headers and Box Headers. .The superior strength and carrying capacity of the HDS means higher performance with fewer members. It eliminates box beam headers, stud-to-track nesting, built-up members for posts and jambs and has superior axial strength . Box beam headers use 2 tracks and 2 studs to create a structural box shaped beam. The tracks are horizontal to the ground with the web of the tracks facing down while the webs of the stud are facing outward with the opening pointed towards each other.

There are two types of headers, L headers, and Box Headers. They discuss the advantages of each one starting on page 32. I like the attached file below for a table on how to size metal stud headers. See page 79 where how to size header spans begin.The Heavy-Duty Stud (HDS®) Framing System is a high-performance, cost effective, multi-purpose, heavy-duty framing stud for headers, jambs, posts and built-up tube truss chords and webs. The superior strength and carrying capacity of the HDS means higher performance with fewer members.Boxed jamb studs welded together reduces material build-up and finish problems. Use of cripple stud to receive head/sill tracks at the jamb studs helps maintain alignment of finishes. Back to back header reduces web-crippling reinforcement requirements.This is a complete detailed instructional video on how to construct a metal stud box beam into a wall, complete with bottom header and layout. Access the lat.

The Steeler Technical Design Catalog is a collection of typical designs for steel framing and connections to help guide with your design process. The Calalog should only be used as a guide, as these are

metal stud size chart

metal stud door header detail

This video shows metal stud framing box beam header styles. Access the latest in construction video right here: https://goo.gl/wSSry6 Master Construction. B. This video will teach you how to build a box beam for metal stud framing. Learn metal stud framing RIGHT HERE: https://bit.ly/ExpertFramingLessons🚧 Best cla.

In steel framing the primary header type used is a box header. The American Iron and Steel Institute did a great deep dive into box beam design and web stiffeners. There are two types of headers: L headers and Box Headers. They .

The superior strength and carrying capacity of the HDS means higher performance with fewer members. It eliminates box beam headers, stud-to-track nesting, built-up members for posts and jambs and has superior axial strength for load-bearing projects. Box beam headers use 2 tracks and 2 studs to create a structural box shaped beam. The tracks are horizontal to the ground with the web of the tracks facing down while the webs of the stud are facing outward with the opening pointed towards each other. There are two types of headers, L headers, and Box Headers. They discuss the advantages of each one starting on page 32. I like the attached file below for a table on how to size metal stud headers. See page 79 where how to size header spans begin.

The Heavy-Duty Stud (HDS®) Framing System is a high-performance, cost effective, multi-purpose, heavy-duty framing stud for headers, jambs, posts and built-up tube truss chords and webs. The superior strength and carrying capacity of the HDS means higher performance with fewer members.Boxed jamb studs welded together reduces material build-up and finish problems. Use of cripple stud to receive head/sill tracks at the jamb studs helps maintain alignment of finishes. Back to back header reduces web-crippling reinforcement requirements.This is a complete detailed instructional video on how to construct a metal stud box beam into a wall, complete with bottom header and layout. Access the lat.

The Steeler Technical Design Catalog is a collection of typical designs for steel framing and connections to help guide with your design process. The Calalog should only be used as a guide, as these are This video shows metal stud framing box beam header styles. Access the latest in construction video right here: https://goo.gl/wSSry6 Master Construction. B. This video will teach you how to build a box beam for metal stud framing. Learn metal stud framing RIGHT HERE: https://bit.ly/ExpertFramingLessons🚧 Best cla.

In steel framing the primary header type used is a box header. The American Iron and Steel Institute did a great deep dive into box beam design and web stiffeners. There are two types of headers: L headers and Box Headers. They .

metal stud box header detail

junction box cover with knockout

Marlin's in-stock metal brackets feature a range of bracket types, including T-plates, mending braces, corner braces, and flat corner braces, and can be purchased from one of our .

box beam header metal stud|metal stud box header detail