rapid prototyping using cnc machining CNC Rapid Prototyping is a process that utilizes CNC machines to create physical prototypes directly from CAD data. It combines the power of Computer Numerical Control (CNC) technology with the agility of Rapid . We produce & distribute subsea electric connectors, cables for underwater use, fiber optic connectors, waterproof connectors & cables.

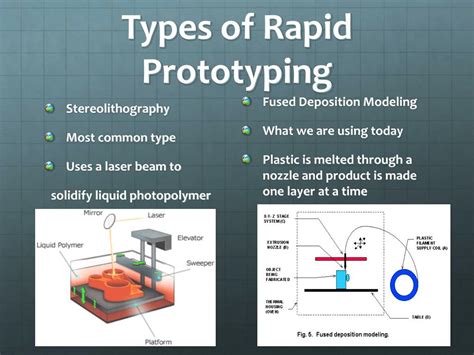

0 · types of rapid prototyping methods

1 · types of rapid prototyping machines

2 · rapid prototyping services near me

3 · rapid prototyping pros and cons

4 · rapid prototyping companies near me

5 · rapid prototyping companies in usa

6 · rapid prototyping cnc machining

7 · cnc machining rapid prototype manufacturer

The estimate average salary for Sheet Metal Workers Union employees is around $70,431 per year, or the hourly rate of Sheet Metal Workers Union rate is $34. The highest earners in the .

Rapid prototyping is a typical early step in the product development process. It is a fast and reliable iterative approach involving the use of CNC machining or 3D computer-aided design (CAD) to fabricate a physical .Discover the world of rapid prototyping, its history, technologies, pros and cons, and the industries that benefit from it. Learn how 3D printing and CNC machining revolutionize prototyping, and .

CNC rapid prototyping is a subtractive manufacturing process that uses computer numerical control (CNC) machine tools to create physical prototypes or product models. The machine tool is controlled by a computer .

mckinnis roofing & sheet metal

As such, CNC machining is a rapid prototyping technique that can be used to create high-quality prototypes in a timely manner. What are the 3 types of prototyping? Prototyping is an important step in the product development . CNC Rapid Prototyping is a process that utilizes CNC machines to create physical prototypes directly from CAD data. It combines the power of Computer Numerical Control (CNC) technology with the agility of Rapid .Rapid CNC prototyping uses a variety of machining processes, including milling, drilling, tapping, threading, slotting, and more. First, the CAM software finds the best machining path, and then the CNC machine executes that information after setting up .Sanwo Rapid Manufacturing Co.,Limited is a China Rapid Prototype and rapid manufacturing company Located in Shenzhen, China, covering more than 6000 Square Meters with a Rapid prototype factory, a mass production factory and .

Rapid Protos is the best company to work with if you need precision CNC machining services to make prototypes and parts. ISO 2768-f is our standard for metal CNC machining, and ISO 2768-m is our standard for plastic CNC .

types of rapid prototyping methods

When you need to order detailed and functional prototypes for a product or part, CNC prototype machining is a tried-and-true process that may suit your project perfectly. In this article, we will take a deeper look into the CNC prototype machining process, its advantages and applications, how it compares to other rapid prototyping technologies, and how to progress from CNC . On the contrary, numerical control machining (NC machining) and high-speed machining (HSM) provide new possibilities for rapid prototyping. Combining the experience of the aviation and mold industries, engineers can use block or bar stock as blank materials through CNC programming and efficiently manufacture rapid prototypes on CNC machine tools.

From rapid prototype CNC, rapid CNC services, custom CNC parts, aluminum CNC milling, to CNC lathe services, we're your one-stop shop for all your CNC machining needs. In the rapidly evolving world of manufacturing, the demand for high-precision, versatile, and efficient production methods is higher than ever.CNC Machining: A subtractive process using computer-controlled tools to remove material from a solid block. This method, known as CNC rapid prototyping, is suitable for creating high-precision parts and prototypes from metals, plastics, and composites, offering quick turnaround times for accurate and reliable prototypes.

Prototype CNC machining is to create a physical model of a product using Computer Numerical Control (CNC) machining. it is used for creating those parts that . Rapid Prototyping with Production-grade Materials. Prototypes with the same performance and appearance as the final product can more accurately evaluate the design and performance of .

Hawk CNC is an American precision machine shop focused on multi-axis CNC manufacturing and rapid prototyping.We machine precision parts on demand and welcome complex orders, from single prototype parts to low volume production. We are capable and experienced in all phases of development, from product design to product manufacturing. Our shop uses state-of-the-art 3, . For many of the same reasons as the aerospace industry, the automotive industry makes heavy use of both rapid prototyping and CNC machining as part of that process. The use of CNC prototypes allows automotive manufacturers to create, test, and then iterate on working parts of an engine using the eventual end product materials.

In the current era of fast manufacturing, it is essential to use quick prototyping services while developing or improving new products. One of the best rapid prototype machining services is CNC because of its accuracy, speed and flexibility. This article provides a complete overview of CNC prototype machining, its definition, benefits, and applications.

Moreover, CNC machining supports rapid prototyping, allowing manufacturers to test designs before full-scale production. This reduces development time and costs. The automation and repeatability of CNC processes also enhance efficiency, minimizing waste and maximizing productivity, making it an essential technology in the competitive automotive .A: Metal rapid prototyping methods produce high-quality parts. Prototypes made using methods like CNC machining are stronger, more precise, and have superior surface finishes compared to mass-produced parts. The Conclusion. Metal prototyping is a powerful tool that can help transform and accelerate your product development process.CNC Machining vs Rapid Tooling . Rapid tooling involves the quick production of molds, dies, and other tooling components used within injection molding, 3D printing, and CNC machining to produce prototypes or small batches of final parts. . Businesses that plan to use CNC machining for prototype and final part creation can require a high .

Choosing between CNC machining and 3D printing for your prototyping needs depends on the specific requirements of your project. 3D printing offers rapid, cost-effective solutions for complex and iterative designs, while CNC machining provides high precision, material versatility, and superior surface quality for functional prototypes. At Rapid .CNC Machining We can offer fast turn-around, multi-axis, high-speed CNC machining solutions to fulfil most requirements for concept models, prototype parts and low-volume production components. We are able to machine directly from your 3D model and can supply parts from one-off’s, up to low-volume production quantities in a wide variety of materials, including plastics and

mazak cnc use parts

Home CNC Machining Services Bespoke manufacturing services of CNC machined parts, from one-off prototypes to full mass production. Request a CNC machining quote today. Submit A Part What is CNC Machining? There are .Today, CNC machining, a computer-aided manufacturing process, is one of the most relied-upon manufacturing technologies among product development teams and engineers for creating custom metal and plastic parts and one of our top choices for rapid prototyping (RP).Here are six reasons why: 1. CNC is fast. CNC machining is an incredibly fast method of rapid prototyping .Protolabs is the world’s fastest source for custom prototypes and low-volume production parts. Get an interactive online quote with free design analysis within hours. . CNC Machining. Leverage the same speed, precision, and reliability in machining that you’re accustomed to at Protolabs but unlock advanced machining capabilities like . Kaito international CO Ltd opened its doors in 1968 in Hongkong, And build 5 facilities in Dongguan China mainland. Since our foundation, we have specialized in the area of engineering, developing and manufacturing of plastic injection mold and die-casting molds, precision mold components, and CNC machining.

Leading exporter of rapid CNC prototyping products, stamping parts and precision CNC components.We are a manufacturer with highly experienced workers. Call Us : +86-769-38988862 | [email protected] For small firms and startups, traditional machining technologies can be expensive and time-consuming. However, CNC prototype machining offers businesses or manufacturing companies that want to produce parts and components a quick, cost-effective way that maintains precision and quality. One major reason why CNC prototype machining is becoming the first .

types of rapid prototyping machines

rapid prototyping services near me

Rapid Prototyping using CNC Machining (CNC-RP) is a method that has been developed which enables automatic generation of process plans for a machined component. The challenge with CNC-RP is not . The advantages of rapid prototyping CNC machining of iron parts lie in its high precision, high efficiency, and high automation, which can ensure stable and reliable part quality. However, the disadvantages include high equipment investment, high requirements for operator skills, and the need for proper handling of the noise and iron filings . CNC prototyping is a precise, and accurate process. It accommodates a variety of materials providing a great deal of variations. Several CNC machines improve these characteristics making the process more flexible. However, knowing how to apply those techniques to CNC prototyping is quite important. This way, it is possible to know the best . CNC-RP: A technique for using CNC machining as a rapid prototyping tool in product/process development. Proceedings of the 11th Annual Industrial Engineering Research Conference, Orlando, FL, May 19–22, 2002, Citeseer. (Open in a new window) Google Scholar.

mclaren metal fabricators

Our production lines and rapid prototyping use industry-leading technology to ensure manufacturing precision and accuracy. . The world of Computer Numerical Control (CNC) machining is a marvel of modern manufacturing, where precision meets efficiency to create . October 22, 2024 .

rapid prototyping pros and cons

Outdoor electrical junction boxes are designed to keep sensitive electrical connections protected and secure in any environment, even underground. Meeting a variety of NEMA and IP ratings ensures our waterproof junction boxes are robust and durable for outdoor use, but they can also be used for indoor applications.

rapid prototyping using cnc machining|rapid prototyping pros and cons