cutting process in sheet metal Sheet metal cutting is a fundamental process in manufacturing that involves various techniques such as laser, plasma, and waterjet cutting. This article provides a comprehensive guide to these methods, exploring the principles behind each .

1. Carbide 3D Shapeoko 4: Best Wood CNC Carving Machine for DIYers; 2. BobsCNC Evo 4: Best CNC Wood Router for the Money; 3. Axiom Iconic Series: User-Friendly Wood Carving Machine; 4. BobsCNC KL744: Best Large CNC Machine for Woodworking; 5. ZMorph Fab: Most Versatile Wood CNC Machine

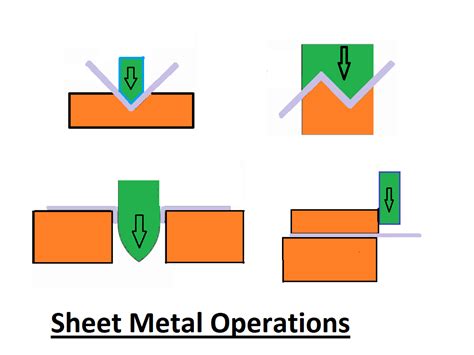

0 · sheet metal operations with diagrams

1 · sheet metal manufacturing process types

2 · sheet metal manufacturing process pdf

3 · perforating operation in sheet metal

4 · notching operation in sheet metal

5 · how to fabricate sheet metal

6 · cutting clearance for sheet metal

7 · blanking operation in sheet metal

Shop Wayfair for the best wood shelf with metal brackets. Enjoy Free Shipping on most stuff, even big stuff.

1. NCT Machining Principle NCT, or Numerical Control Machine Tool, is a flexible automated machine tool that can adapt to frequent changes in product design. The various operations and steps required during the machining process, as well as the relative displacement between the tool and the workpiece, are . See more1. The definitions of X and Y directions are as follows: The X direction is parallel to the two jaws, and the Y direction is parallel to the locating pin or locating column. See the diagram below: . See more

There are various ways of NCT processing, such as punching mesh holes, step punching, nibbling, chamfering, automatic clamp movement, etc. Each processing method . See more1. Anti-misoperation For asymmetric workpieces that are difficult to distinguish direction or have left-right symmetry, foolproofing measures must be taken to prevent the . See more Sheet metal cutting is a fundamental step in sheet metal fabrication, which involves splitting sheet metal pieces and the creation of . Sheet metal cutting is a fundamental process in manufacturing that involves various techniques such as laser, plasma, and waterjet cutting. This article provides a comprehensive guide to these methods, exploring the principles behind each .

sheet metal operations with diagrams

Sheet metal cutting is a fundamental step in sheet metal fabrication, which involves splitting sheet metal pieces and the creation of desirable shapes by cutting into the designated area. Any sheet metal fabrication project starts with cutting the sheet metal into the required sizes and shapes.

ancient boxing metal inserts

The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form . Sheet metal fabrication is a set of manufacturing processes for turning sheet metal into functional parts. For this guide, we have divided the processes into three categories: cutting, deformation, and assembly.

Laser cutting involves using a high-powered laser beam to melt, burn, or vaporize the material along the desired cutting path. Similarly, plasma cutting utilizes a plasma torch to cut through electrically conductive materials.Here are three key steps in the metal cutting process: Transferring Design to Metal: The precise measurements and patterns from the design phase are transferred onto the selected sheet metal. This is often done using computer-aided manufacturing (CAM) software, which ensures accuracy and minimizes the risk of errors. Sheet metal cutting, a fundamental process in the metalworking industry, involves the precise removal of material from sheet metal stock to form a specific part or component. This process, essential in shaping the metal sheet into a finished part, employs various tools and techniques, ensuring accuracy and efficiency.

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. Sheet metal is made from various materials, including steel, aluminum, zinc, and copper.For a piece of metal to become a product, the metal will eventually have to be cut. As diverse as the metal shapes are, so are the cutting processes. In this article, we give you an overview of what is relevant for industrial sheet metal processing.Sheet metal cutting operations remove the sheet metal material from larger sheets by applying high forces on the cutting edge. The cutting tool (punch & die, or shearing blade) cuts the material if the applied shear stress exceeds the material’s shear strength. Sheet metal cutting is a fundamental process in manufacturing that involves various techniques such as laser, plasma, and waterjet cutting. This article provides a comprehensive guide to these methods, exploring the principles behind each .

Sheet metal cutting is a fundamental step in sheet metal fabrication, which involves splitting sheet metal pieces and the creation of desirable shapes by cutting into the designated area. Any sheet metal fabrication project starts with cutting the sheet metal into the required sizes and shapes. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form . Sheet metal fabrication is a set of manufacturing processes for turning sheet metal into functional parts. For this guide, we have divided the processes into three categories: cutting, deformation, and assembly.

Laser cutting involves using a high-powered laser beam to melt, burn, or vaporize the material along the desired cutting path. Similarly, plasma cutting utilizes a plasma torch to cut through electrically conductive materials.Here are three key steps in the metal cutting process: Transferring Design to Metal: The precise measurements and patterns from the design phase are transferred onto the selected sheet metal. This is often done using computer-aided manufacturing (CAM) software, which ensures accuracy and minimizes the risk of errors.

Sheet metal cutting, a fundamental process in the metalworking industry, involves the precise removal of material from sheet metal stock to form a specific part or component. This process, essential in shaping the metal sheet into a finished part, employs various tools and techniques, ensuring accuracy and efficiency.Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. Sheet metal is made from various materials, including steel, aluminum, zinc, and copper.For a piece of metal to become a product, the metal will eventually have to be cut. As diverse as the metal shapes are, so are the cutting processes. In this article, we give you an overview of what is relevant for industrial sheet metal processing.

Add flowers to your outdoor space with one of these DIY planter box designs! They all have woodworking plans so you can start building today!

cutting process in sheet metal|sheet metal manufacturing process pdf