metal roofing sheets manufacturing process pdf The article presents the main conclusions from the process of the implementation and expoitation of ERP system by the leading manufacturer of roof and facade metal sheets in . A junction box, also called a j-box or a summing box, brings multiple load cells together so they can function as a single scale. A junction box houses wire connections from multiple load cells .

0 · galvanized zinc roofing process

1 · galvanized zinc roofing pdf

2 · galvanized roofing sheets reviews

3 · galvanized roofing process pdf

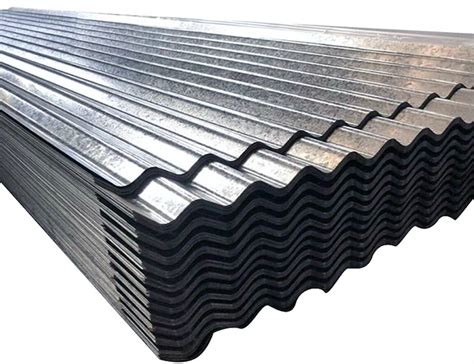

4 · galvanized metal sheets

5 · galvanized metal roofing sheets

6 · corrugated iron roofing process

Note: In a Booster Box (20 Packs) you will atleast get 1x SP or RR or SR, 4x RR (1 RR of each colour), 15x R. Also a set of CR (1 CR in each colour, 4 in total) and 2 sets of CC (2 CC in each colour, 8 in total) of the Series.

galvanized zinc roofing process

The article presents the main conclusions from the process of the implementation and expoitation of ERP system by the leading manufacturer of roof and facade metal sheets in .The article presents the main conclusions from the process of the implementation .© 2008-2024 ResearchGate GmbH. All rights reserved. Terms; Privacy; IP .

Abstract. In search for solution to the challenges posed by the degradation of roofing steel sheet in an aggressive environment, galvanization of steel sheet for roofing of buildings and .

This mini review provides insight to the production process, stages and properties of galvanized roofing steel sheet use in Nigeria and most part of Africa. Content from this work .

2. Manufacturer shall operate a permanent, full-time, manufacturing facility where the metal roof panels are produced on fixed based multi-station roll forming machines that are included in the .commentary on structural methods and construction using stainless steel sheet roofing. In Japan, construction clients, architects, roof sheet metal workers and roofing contractors are using this .At Helix Metalforming, we pride ourselves on producing top-quality metal roofing sheets through a meticulous manufacturing process. The journey of a metal roofing sheet begins with selecting .

The following guide is intended to help you select the perfect metal roof for your home by arming you with information on the base metals, product types, product profiles, installation issues .

Galvanized Corrugated Sheets are manufactured using best grade steel and is widely applied in construction industry. Galvanized Corrugated Sheets have excellent corrosion resistance, . In this factory video tour, we will show you a metal roofing sheet making process for your ease. So, watch this video till the end.

Other Roofing Products – Perforated Metal Sheet Perforated metal Sheet is made through the metal stamping and manufacturing process. This is a sheet or plate with round holes punched in it or expanded metal. Perforated materials are very versatile. From lightweight decorative elements to load-bearing structuralroofing sheet (metal) manufacturing The project report includes Present Market Position and Expected Future Demand, Market Size, Statistics, Trends, SWOT Analysis and Forecasts. Report provides a comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT analysis .But, many of these same attributes also best serve DECRA’s desire to manufacture high-quality stone coated DECRA Metal Roofing systems. Roofing granules serve several important functions, including providing roofing panels with vibrant color blends and a desirable surface texture. Roofing granules are manufactured from natural stone. Metal roofing is still metal and needs to be heated in order to attain a shape that will fit a residential roof. The component that heats the metal as it is fed through the uncloiler is called a heat box. The panels are heated at 1,000 degrees which softens the metal just enough to allow the steel to be shaped into the appropriate roof style slats.

A manufacturer of corrugated metal roofing has some scrap sheets of metal laying around the shop. The standard manufacturing process produces corrugated sheets that are 2 inches thick and that have a profile given by y= sin[(pi*x) / 7]. Verify that this equation results in a corrugated panel that is 2 inches thick. A roof sheet manufacturing business manufactures roof sheets in various configurations (corrugated, inverted box rib, concealed fix etc.). This business involves buying the rolls of flat sheet metal from a manufacturer such as Mittal and then fabricating, cutting it to size and then reselling it to a building supply company, hardware stores or even directly [.]

galvanized zinc roofing pdf

How Do I Manufacture Galvanized Roofing Sheets in India? The manufacturing process of galvanized roofing sheets typically involves the following steps: Steel or Iron Sheet Preparation: The first step in the manufacturing process is to prepare the base material, which is typically a sheet of steel or iron. The steel or iron sheet is cleaned to .Manufacturing Process. Our decoiling process, roll-forming process, metal roofing sheets, automated PU foam machine for metal roofing sheets, PU foam alignment and cutting, PU foam steel sheets and finished goods, the entire process is . This guide covers configurations, process overview, forming capabilities, components, suppliers, and comparative assessment. . Galvanized steel roof sheets are a smart choice for those seeking a durable, weather-resistant, and low-maintenance roofing solution. . Sunway Manufacturing; Wuxi Sunway; Contact +86-13616182007 [email protected .UL 90 - Uplift test of roof system. UL 1897 - Uplift test of roof system. UL 790 - Fire test of roof system. UL 263 - Fire test of construction and materials. UL 2218 - Impact resistance of prepared roof covering materials. ASTM E-1592 - Structural performance of sheet metal roof and siding systems by uniform static air pressure di˝erence.

The term “metal roof” is a category of roofing material. Many people automatically assume, when they hear “metal roofing,” that the “metal” being referred to is steel. Steel is a common metal roofing product that is widely used in Agricultural, Commercial and Industrial metal roofing projects in one form or another.

The corrugated roof sheet manufacturing is a booming industry with an omni present demand from commercial, industrial and agricultural sector consumers.This business even though might require a heavy amount of investment, comes with less need for maintenance and a precise profit margin varying between 60%-80% every financial year and suffice rate of return.Lastly, this .Advance Roofing Technology. JSW Colouron + Premium Colour Coated Roofing Sheets. JSW Pragati + Colour Coated Sheets. JSW Vishwas. Premium GC Sheets. JSW Vishwas + Premium Al-Zn Sheets. JSW Galvos. Premium Galvalume Sheets for Solar Structures. JSW Platina. Tinplate – Best Packaging Medium. JSW Silveron+. JSW Silveron+Galvalume® sheet. Manufacturing Facilities Manufacturing Process Tarapur Works JSW's Tarapur works is the largest coated steel plant in a single location specializing in the manufacturing of ultra-thin coated products. The plant offers coated products catering to several sectors and located about 100 km from Mumbai.Today, UGC is the market leader in the manufacture and distribution of prepainted and other galvanized roofing and of galvanized steel building products such as building system components like steel deckings, c-purlins, door .

ROOFING SHEET (METAL) MANUFACTURING [CODE NO.3618] Galvanized Corrugated Sheets are manufactured using best grade steel and is widely applied in construction industry. . Manufacturing Process, Investment Opportunity, . ELECTRIC TWO WHEELER ( CODE NO.3732)Download PDF Electric two-wheelers, as indicates itself, is electricity-powered two .Detailed project report on metal roofing sheet - Get comprehensive project reports, formulations, startup guides, and expert consultancy for business success - Great online business ideas, Best small business ideas, Entrepreneur magazine, Small scale busi . Manufacturing Process, Investment Opportunity, . ELECTRIC TWO WHEELER ( CODE NO.3732 .

In search for solution to the challenges posed by the degradation of roofing steel sheet . in an aggressive environment, galvanization of steel sheet for roofing of buildings and . Galvanized steel sheets have been widely used by various manufacturing . company. Occasional switching from steel to other metal like aluminum have not been .304/304L Stainless Steel Sheet . 304/304L Stainless Steel Plate . 316L Stainless Steel Plate . 316L Stainless Steel Sheet . 430 Stainless Steel Sheet . 201/201LN Stainless Steel Plate . . Metal roofing manufacturing is the process of producing metal roofing systems, which are used to cover buildings and provide protection from the elements. . Occasional switching from steel to other metal like aluminum have not been cost effective because of the present economically situation. This makes substituting galvanized steel difficult. This mini review provides insight to the production process, stages and properties of galvanized roofing steel sheet use in Nigeria and most part of Africa.

installation of metal roofing over a continuous rigid substrate such as plywood/OSB, or over spaced supports. Contact ASC Building Products for additional information. The following steps need to be taken to prepare the roof for installation of metal roofing panels: New Roofs: 1. Make sure there are no nails or other objects protruding from

STANDING SEAM SHEET METAL ROOF PANELS 07 41 13 SPECIFICATION DATA This specification data sheet is provided by Metal Sales Manufacturing Corporation as a technical support tool incident to the sale of its Magna-Loc Roof Panel products. Contact Metal Sales for more information on these and other products. Telephone: 800.406.7387 metalsales.us.com

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking OperationsAt Helix Metalforming, we pride ourselves on producing top-quality metal roofing sheets through a meticulous manufacturing process. The journey of a metal roofing sheet begins with selecting the appropriate raw material. Typical metals used for roofing include steel, aluminum, copper, and . The Ultimate Guide to roof sheet roll forming machines Roof sheet roll forming machines are essential equipment for the production of high-quality roofing sheets. These machines use a continuous process to transform metal coils into perfectly shaped roofing panels with consistent dimensions. In this comprehensive guide, we will explore the various aspects . In this post, let’s see the process and post-process involved in manufacturing the sheets. The knowledge about the product will surely help you to purchase a better product. . The metal roofing in Chennai uses a computer control unit to make changes in speed, control, operation, and panel length. The mill engineers adjust the roller machine .

Sheet Metal Gauge Chart of Sizes Keywords: sheet metal gauge chart, sheet metal gauge size, sheet metal thickness, sheet metal gauge Created Date: 2/15/2011 3:35:40 PM .These are American (Brown & Sharpe) Gauges.

metal roofing sheets manufacturing process pdf|galvanized zinc roofing pdf