sheet metal joint design The Sheet metal material selection during product design impact the sheet metal . Western Sheet Metals, Inc. If you can draw it, We can build it! Western Sheet Metals takes pride in providing high quality custom sheet metal fabrication and installation services.

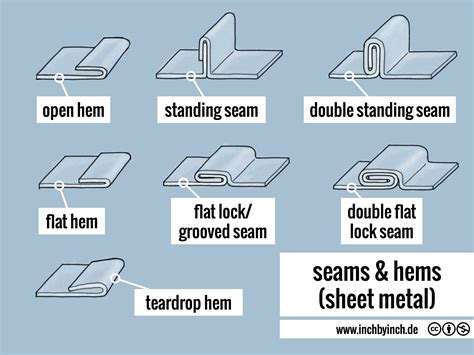

0 · types of sheet metal seams

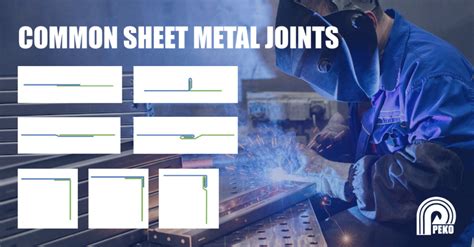

1 · types of sheet metal joints

2 · sheet metal overlap joint

3 · sheet metal joints pdf

4 · sheet metal clinching joint

5 · interlocking sheet metal joints

6 · interlocking sheet metal design

7 · how to attach sheet metal

$14.00

Sheet metal joining operation is crucial part of the sheet metal fabrication process. Joint reliability depends on its type, sheet metal material, and manufacturing process. This article covers .

Mechanical Design Basics (24) Mechanism (13) Plastic Design (15) Product Design .The Sheet metal material selection during product design impact the sheet metal . Learn how sheet metal joints are made and used in the HVAC sheet metal industry to make air conditioning ductwork. Typically used on aluminum parts over 0.40” thick, open corner joints can be welded using several methods: fillet/seam, fuse, tack, or stitch welding. Our expert welders can determine the right approach based on the .

How can we ensure secure and durable connections in sheet metal fabrication? This article explores various joining and fastening techniques, including TOX riveting, welding, and nail riveting. You'll discover the pros and .

types of sheet metal seams

types of sheet metal joints

Sheet Metal. Welding and Fabrication in Metal Joining: A Comprehensive Guide. Metal joining process in manufacturing and construction is essential for creating various structures and products. Two standard methods employed for metal .Learn about the principles of joint design from the brazing and metal joining experts at Lucas Milhaupt.Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre-work. These methods include, mechanical fastening, welding, rivets, brazing and soldering, tongue and .Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs.

Discover the 7 most common sheet metal joint techniques that include riveted, welded, and adhesive joint types for appropriate enhancement of structural rigidity and effectiveness in your projects. . A prediction of the load .Further reduction of dimensional variation depends on the improvement of product/process design. especially the design of joints for sheet metal pans (Ceglarek et al.. 1993). 1.2 Literature Review. Although product and process . Design of Y joint in Solidworks with the help of sheet metal tools.Please subscribe our channel for more videos and projects in Solidworks. Please Like and s.

- 2 - Forming Basics Press brake forming-The fundamental advantage of a press brake as a forming tool is its flexibility. By using standard vee-dies, cost savings can be realized through economical set-ups and run times on small lots and prototypes. Add seam joint lock in a sheet metal part in Creo Parametric

sheet metal overlap joint

Thank you Ryan. I ended up creating new blank components and recreated the sheet metal parts in there. The Joint functions are now working. In the past I had created new files and bringing in derives, unlinking them, converting them back into sheet metal parts and inserting them into an "Assembly" file.Further reduction of dimensional variation depends on the improvement of product/process design. especially the design of joints for sheet metal pans (Ceglarek et al.. 1993). 1.2 Literature Review. Although product and process design impact one another. product design has traditionally been separated from process design. Lately. manufacturers .

These range from tools for the design of sheet-metal parts with Solid Edge as educational tools , and assisted manufacturing for drawing sheet-metal parts , to . These last intersection points are then joined, thereby forming the design of the joint between the first two ferrules. It should be borne in mind that by increasing the number of . The design of joints between parts is one of the most critical issues in the design of sheet metal assemblies. This paper presents a new part-to-part joint design evaluation index developed for .It is possible in sheet metal product design to assemble parts without fasteners. (Image source) (Image source) Assembly with Inbuilt Hooks (Image Courtesy: Pelican Shelving) One wonderful property of sheet metal is its rigidity yet at the . Clinching joint is a sheet metal operation to permanently join two sheets together This method can be .Here is the list of best sheet metal design interview questions with their answers. What is recommended inside bending radius in sheet metal fabrication? For hard materials (CRCA and stainless steel), the minimum inside radius is 0.7 times of sheet thickness. . Lap Joint, Hem Joint; Riveting; Press Fitting: PEM Inserts; Check out in detail .

metal boxer dog statue

Multiply 1/8 by 2 1/2 and your answer will be 5/16 inch, which you will allow when laying out sheet metal for making the wire edge. Joints. The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used methods for joining light- and medium-gauge sheet metal. It consists of two folded edges that are locked together with a HAND GROOVER (fig .The design of the Cantilever snap Joints is spring-based. It firmly fastens two parts together. . The dynamic and adaptable field of snap fit design for sheet metal provides innovative solutions to an extensive variety of industries. Through an understanding of snap fit’s characteristics, features, and applications as well as typical .Sheet metal fits all “green” building materials measures, especially recycled content – Recycled content: steel = 25%; roofing copper = >75%; – Energy efficiency per Florida Solar Research = light-colored metal roofs VERY energy efficient Soldered sheet metal joints are “sustainable” and do not require continuous maintenance—unlike The metal tabs that are to be bent should be between 0.12 and 0.8 in. thick. And the metal should have the ductility to stay in place and not spring back after being bent.

A. Sheet Metal Fabrication Standard: Fabricate sheet metal flashing and trim to comply with recommendations of SMACNA's "Architectural Sheet Metal Manual" that apply to the design, dimensions, metal, and other characteristics of the item indicated. B. Comply with details shown to fabricate sheet metal flashing and trim that fit substrates and Hemming involves folding the edge of one sheet over another, creating a secure joint. Flanging, on the other hand, creates a flange or lip along the edge of a sheet, which can serve as a reinforcement or attachment point. .In Onshape, you can initiate a sheet metal design using several methods: you can convert a solid part into sheet metal; design from a flat sketch, then fold; use flange tools to add edges and features; or directly import and adapt existing sheet metal designs. Simultaneous Sheet Metal.

In the design of sheet metal structure, the rigidity of sheet metal structural parts is often not met. . The riveting process is relatively simple, and the joint strength is low, and is usually used to limit the height of the fastener and to withstand a .Joint design – Specific stress resistance is a major consideration. . Corner joints – sheet metal Corner joints can be assembled with adhesives by using simple supplementary attachments. This permits joining and sealing in a single operation. Typical designs are right angle butt joints, slip

The design of joints between parts is one of the most critical issues in the design of sheet metal assemblies. This paper presents a new part-to-part joint design evaluation index developed for dimensional control of sheet metal assemblies. The proposed index provides a new analytical tool to address the dimensional capabilities of an assembly process in the early .The objective of this work is to investigate the shear capacity of small end distance lap joints in sheet steel fastened with a single bolt. For bolted connections in shear, the current American Iron and Steel Institute (AISI) specification does not differentiate between tilting limit states, in which the fastener rotates and thin sheet curls, and nontilting limit states, such as bearing and . The sheet metal bodies can be split up to individual sheet metal components and they can be joined to other components. However, only the moldings on the left and right side of the box can have a joint origin point at the center of the bend radius, because it has a flat side.Understand Metal Joining Processes. Metal joining combines two or more metal components to create a unified structure. This process is crucial in various applications, from constructing buildings and bridges to manufacturing vehicles, machinery, and everyday appliances.By fusing metal pieces, engineers and fabricators can form solid and reliable connections that ensure .

This Pin was discovered by Nic Batchelor. Discover (and save!) your own Pins on PinterestExpansion Joints Only (See Note #9) Sheet Metal Bottom Strip For DOWELS (LENGTH 18") LONGITUDINAL JOINTS TRANSVERSE JOINTS Diameter "D" Pavement Thickness 3" Min. 2" Min. " 1 6 1 d + d 2" Min. 3" Min. " 1 6 1 d + d L D D / 2 . DESIGN STANDARDS07/01/00 2of4 FY 2017-18 CONCRETE PAVEMENT JOINTS 305 As Specified In The Plans Joint Sealant .

sheet metal joints pdf

Junction boxes protect electrical wires from damage, prevent shocks, and stop sparks from igniting flammable material nearby. To install one, you’ll need to strip the ends off all the wires that will be in the box. To .

sheet metal joint design|types of sheet metal seams