cnc barrel rifling machine PD Browne Machine Tools specializes in CNC Precihole Broach Rifling Machines. Quality machines, parts and service at reasonable rates.

All resistors have the same efficiency, they convert the dissipated power to heat. The answer depends on whether you want to heat air or a surface. A resistor that is mounted to the chassis with screws will transfer the heat to a surface more efficiently.

0 · techniques for rifling a barrel

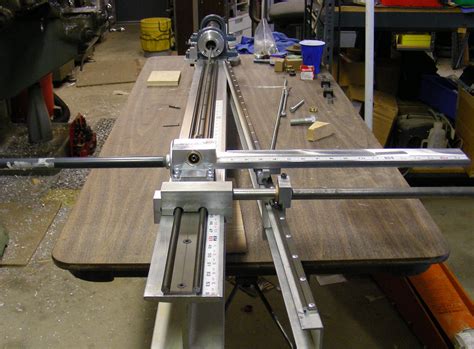

1 · sine bar rifling machine plans

2 · rifle barrel making equipment

3 · pratt and whitney rifling machine

4 · homemade barrel rifling machine

5 · cut rifled vs button

6 · broach cut rifling vs button

7 · barrel rifling explained

RACO Handy Boxes- the ideal utility box for both new and old applications in ceilings or walls. This versatile box is specifically designed for convenience outlets, switch boxes, or small junction boxes, making it a popular choice for exposed work applications.

Precihole Barrel Rifling Machines. The rifling process is a key part of barrel manufacturing, as rifle and pistol barrels require rifling to shoot accurately. Rifling refers to the spiral grooves that are .

Precihole’s Cut Rifling Machines produce extremely accurate and precise barrels .The Gun Barrel line of machines from DeHoff are specifically designed for the manufacture of gun barrels. We offer several different types of machines with options for caliber size, barrel length, .Broach rifling creates spiral grooves in the barrel by removing steel using a hook cutter. The linear and rotary motion of the hook cutter are precision controlled .R-Series rifling machines have a compact footprint with minimal installation, automatic tool lubrication, and are available robot-ready or full automation. These machines utilize optimal rifling technology for each caliber of barrel for .

PD Browne Machine Tools specializes in CNC Precihole Broach Rifling Machines. Quality machines, parts and service at reasonable rates.Precihole’s Cut Rifling Machines produce extremely accurate and precise barrels by cutting grooves using a single point cutting tool. The workpiece is clamped rigidly in a self-centering vice. Servo controls ensure precision indexing and .

techniques for rifling a barrel

Precihole Button Rifling Machines incorporate the latest features to form precision grooves in small caliber weapon systems. The rifling button is pulled and rotated precisely through the barrel. Precision in rifling is critical.DeHoff models include gun barrel drilling and reaming machines, and the original CNC Button Rifling machine, the first of its kind in the world. Kays Engineering is also the only company in the world to offer the “full package” of gun barrel .Precihole Button Rifling Machines incorporate the latest features to form precision grooves in small caliber weapon systems. The rifling button is pulled and rotated precisely through the barrel. Precision in rifling is critical.

Precihole Barrel Rifling Machines. The rifling process is a key part of barrel manufacturing, as rifle and pistol barrels require rifling to shoot accurately. Rifling refers to the spiral grooves that are cut into the internal surface, known as the bore, of a gun barrel.The Gun Barrel line of machines from DeHoff are specifically designed for the manufacture of gun barrels. We offer several different types of machines with options for caliber size, barrel length, and number of spindles to meet your particular barrel manufacturing needs.Broach rifling creates spiral grooves in the barrel by removing steel using a hook cutter. The linear and rotary motion of the hook cutter are precision controlled for accuracy using a servo drive and ball screw or rack and pinion mechanism.R-Series rifling machines have a compact footprint with minimal installation, automatic tool lubrication, and are available robot-ready or full automation. These machines utilize optimal rifling technology for each caliber of barrel for precision grooves.

PD Browne Machine Tools specializes in CNC Precihole Broach Rifling Machines. Quality machines, parts and service at reasonable rates.

Precihole’s Cut Rifling Machines produce extremely accurate and precise barrels by cutting grooves using a single point cutting tool. The workpiece is clamped rigidly in a self-centering vice. Servo controls ensure precision indexing and pulling to cut grooves.Precihole Button Rifling Machines incorporate the latest features to form precision grooves in small caliber weapon systems. The rifling button is pulled and rotated precisely through the barrel. Precision in rifling is critical.DeHoff models include gun barrel drilling and reaming machines, and the original CNC Button Rifling machine, the first of its kind in the world. Kays Engineering is also the only company in the world to offer the “full package” of gun barrel manufacturing equipment, which takes you from empty factory floor to making finished gun barrels.Precihole Button Rifling Machines incorporate the latest features to form precision grooves in small caliber weapon systems. The rifling button is pulled and rotated precisely through the barrel. Precision in rifling is critical.

Designed as a reliable, high-precision solution for gun manufacturers, UNISIG’s dedicated R-2A rifling equipment performs the most critical final steps of firearm manufacturing. The R-2A barrel rifling machine finishes barrel blanks with .Precihole Barrel Rifling Machines. The rifling process is a key part of barrel manufacturing, as rifle and pistol barrels require rifling to shoot accurately. Rifling refers to the spiral grooves that are cut into the internal surface, known as the bore, of a gun barrel.

The Gun Barrel line of machines from DeHoff are specifically designed for the manufacture of gun barrels. We offer several different types of machines with options for caliber size, barrel length, and number of spindles to meet your particular barrel manufacturing needs.Broach rifling creates spiral grooves in the barrel by removing steel using a hook cutter. The linear and rotary motion of the hook cutter are precision controlled for accuracy using a servo drive and ball screw or rack and pinion mechanism.R-Series rifling machines have a compact footprint with minimal installation, automatic tool lubrication, and are available robot-ready or full automation. These machines utilize optimal rifling technology for each caliber of barrel for precision grooves.PD Browne Machine Tools specializes in CNC Precihole Broach Rifling Machines. Quality machines, parts and service at reasonable rates.

Precihole’s Cut Rifling Machines produce extremely accurate and precise barrels by cutting grooves using a single point cutting tool. The workpiece is clamped rigidly in a self-centering vice. Servo controls ensure precision indexing and pulling to cut grooves.

Precihole Button Rifling Machines incorporate the latest features to form precision grooves in small caliber weapon systems. The rifling button is pulled and rotated precisely through the barrel. Precision in rifling is critical.DeHoff models include gun barrel drilling and reaming machines, and the original CNC Button Rifling machine, the first of its kind in the world. Kays Engineering is also the only company in the world to offer the “full package” of gun barrel manufacturing equipment, which takes you from empty factory floor to making finished gun barrels.

Precihole Button Rifling Machines incorporate the latest features to form precision grooves in small caliber weapon systems. The rifling button is pulled and rotated precisely through the barrel. Precision in rifling is critical.

sine bar rifling machine plans

You can use metal and romex, sometimes it is preferable and even necessary to use metal. Larger switch boxes for instance. Plastic has its place and it gets the job done just fine.

cnc barrel rifling machine|techniques for rifling a barrel