what are the parts of cnc code CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool .

The crescent Wiss 2-ring full metal body Scissor features full-length steel blades that extend through the handles for maximum strength. These heavy-duty blades have a titanium coating that is 3 times harder than steel for extra durability and a longer blade life.

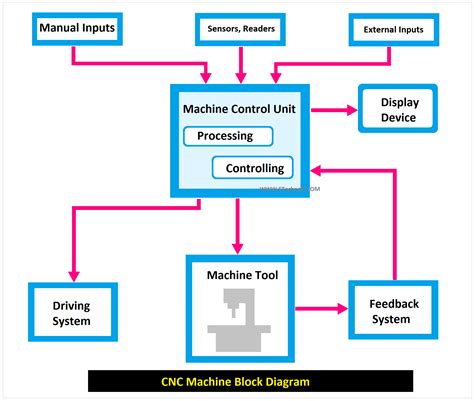

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

2 · main components of cnc machine

3 · cnc machine spare parts list

4 · cnc machine parts list pdf

5 · cnc machine parts list

6 · cnc machine parts diagram

7 · block diagram of cnc machine

$32.79

Below is a list of G codes. They have been organized into group types based on how the machine reacts to the individual code. If you are new to G code, you should review the code groups and compare the codes within a . Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing.

CNC G-codes & M Codes for milling and turning with explanations, . In a CNC machine, the M code is part of the NC (Numerical Control) program that is executed by the machine’s control unit. When the NC program is run, the control unit reads . CNC programming is a vital aspect of the CNC machining process. It involves using the G-code language to describe the shape, process, parameters, and auxiliary information of a part. The CNC programmer writes . CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool .

Instead of manually operating machines like lathes, mills, or grinders, CNC technology lets manufacturers automate the machining process by feeding the machine a .

CNC programming is the process of converting a 3D model into machine-readable instructions in order to perform automated machining operations. Learn more about it here.

By dissecting codes from G00 for Rapid Positioning to G21 for Millimeter System Selection, we’ve seen how each code serves a specific function, contributing to the efficiency, precision, and versatility of CNC . G-codes in CNC machining transform complex operations into methodical tasks, with standardized codes ensuring consistency and peak performance. Here’s a look at some key G-Codes crucial for anyone working . Quick fun projects someone could CNC in a weekend. Useful g-code utilities such as subprograms that perform certain tasks that others may want to include in their own g-code. G-Code that demonstrates some clever .

Parts of machines and mechanical appliances having individual functions, n.e.s. (excl. of cast iron or cast steel) . HS Code 84799070 - Machine parts, not iron/steel . - High-speed rotation spindle for CNC machines (20 kg, 0.3m long, 0.1m diameter) Code Tree Structure / Hierarchy Imagine if you needed to re-run a portion of the code and started your program after the initial T02 code. If you didn’t repeat the T02 code right before the tool change then the machine would use the last tool number from .

CNC Machine Parts By Type of Technology. CNC machines can be classified by their technological capabilities. Each type uses different parts to achieve specific machining operations. Below, we will discuss the components of 3-axis and 4-axis CNC machines. 3-Axis CNC Machines. 3-axis CNC machines are the most common type used in various industries.

HSN Code Product Description; 8466: Parts and accessories suitable for use solely or principally with the machines of headings 8456 to 8465 including work or tool holders, self- opening dieheads, dividingheads and other special attachments for the machines; tool holders for any type of tool, for working in the hand What are G and M Codes? G and M codes are the basic programming languages for CNC machines. The codes automate the processes by giving the CNC machine a standardized set of step-by-step instructions to follow without human intervention. This allows precise and repeatable cutting of complex 3D parts. G codes control the machine's movements.

The parts of the CNC machines are costly. Maintenance costs are significantly higher in the case of CNC. It does not eliminate the need for costly tools. CNC machine requires skilled programmers. It is not suitable for small-scale production; Maintenance cost is more. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions. Advantages of CNC include easier programming and reducing human errors, while challenges include high setup costs and requiring computer and programming .

AI can analyze CAD models and automatically generate CNC machining G-Code, significantly reducing manual programming time and errors. For example, Autodesk’s Fusion 360 integrates AI technology to automatically identify part features and generate corresponding machining paths. . (Parts) of CNC Machine What is Tool Setter – CNC Tool Setter .About CNC Replacement Parts Promo Codes. Over the last 30 days, coupon average savings for CNC Replacement Parts was .38, and the most savings was .75.; Currently, there are 15 active CNC Replacement Parts coupons: 1 active promo codes, and 14 deals for November 2024. Further more, 2 CNC Replacement Parts coupon codes are hand-tested by HotDeals, and .

schematic diagram of cnc machine

What Are The HS Codes for CNC Machined Parts? HS Codes or Harmonization Codes are names or numbers that classify the parts of the traded products. They are important to classify products on export and to calculate applicable taxes and duties on import. HS codes for CNC machined parts follow the same rules. These codes are 6, 8, or 10 digits long. This article will describe the different parts of a CNC machine. Some parts are common between lathes and mills, like the control unit, driving system, and feedback system, while others are specific to a certain type of machine. For example, tailstocks and headstocks are only found on CNC lathes. 1. Input Device These instructions, also known as G-code, tell the machine how to move the cutting tool and where to remove material from the workpiece. The machine then follows these instructions to produce the desired part or component. . 15 Parts of CNC Machine. A CNC machine consists of several main parts that work together to produce precision parts and . These are easier to remember as “machine functions” because this group of codes controls different parts of the CNC machine such as turning the spindle or coolant on and off. The rest of the CNC codes consist of the remaining letters A through Z.

M codes are the second most common codes used in CNC programming. We’ve laid out what each M code does, but remember that some CNC makers switch things around a little bit. You can bet that the most common codes such as the ones for starting and stopping your spindle, coolant and program will be the same but some of the others might vary. Read-on to understand the parts of a CNC milling machine and their functions. Also know about different accessories and tools used with milling machines. . An ATC can either be mounted on the column or separately from .Introduction. Components of CNC Machine | Parts of CNC Machine: – CNC machines are computerized machines that assume a significant part in the manufacturing industry and provide more steady, effective, and precise . A: G05 CNC code is applied to smoothen the movement of a CNC machine so that it produces parts with a finer finish. It does this by optimizing the interpolation thereby enhancing control of the machine tool as well as ensuring seamless shift between commands.

What are the Parts of a CNC Machine? Bed: Typically constructed from cast iron for enhanced durability and strength, the bed is the machine’s foundation, supporting all components.. Spindle: Inside the machining area, the electrically driven spindle rotates tools that cut and shape the parts. The inside of the spindle is tapered to match the tapered angle of the tool holder to .For CNC machined parts, these codes help customs officials determine the appropriate duties and taxes. Steps to Find the HTS Code for CNC Machined Parts 1. Identify the Product Description. The first step in finding the correct HTS code is to accurately describe the product. For CNC machined parts, consider the following aspects: In the CNC programming world, one must learn G-codes to guarantee accuracy and speed in machining. This article will discuss everything about G11, such as what it does, how it works within CNC environments with its syntax rules, and tips for better programming practices using this particular code.

metal house genre

Q: How does G22 G Code fit into the CNC programming process? A: G Code G 22 is a key part of the CNC programming process. It is used as a reference point in many cnc programs and is one of the first things written in any cnc program file so that all the following operations are done from a known position. The "post" (post processor) generates your start and finish codes that work in your machine. We use several controls so each brand uses a unique start and end, height numbers, safe blocks etc. Manual writing code is probably not the fastest today. Surfacing, 3d contours etc would be very slow to write manually. Can it and has it been done? sure. CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write the G-code program, set up the CNC machine with the appropriate tools and workpiece, and run the program while monitoring for any issues.

Two parts made from the same code should be essentially indistinguishable. How To Determine the Parts of CNC Lathe Machine. To determine the parts of a CNC lathe machine, it is recommended to study the user manual and breakdown images of your machine. You should have a clear understanding of each component before progressing to cutting metal.A. punched paper tape B. automated numerical control C. computer numerical control D. programmed codes, A major advantage of using CNC equipment of manual equipment is that it _____. A. duplicates its actions perfectly for every part B. costs less initially than the manual equipment C. is an option that can be used by even the smallest .spare parts for cnc milling machine (maintenance parts for replacement (maintenance parts bearing for y axis) japan: hyderabad air cargo: nos: 7: 731: 104.41: nov 30 2013: 84592100: 2 spindle cnc machine (with standard spare parts) (cnc router drilling machine) ( captive consumption ) china: patparganj: nos: 1: 9,839: 9,839.42: nov 14 2013: .

metal house number signs uk

$9.98

what are the parts of cnc code|cnc machine parts list pdf