how do you set work part zero on cnc machine 1. Using an Edge Finder. Using an edge finder is a common and effective method for setting Part Zero in a CNC router setup, especially on flat surfaces. This tool, essential for precision, helps accurately locate the edges . Designed to withstand the elements, this large junction box provides ample space for secure cable connections. The grey exterior blends seamlessly with .

0 · part zero cnc machine location

1 · part zero cnc machine

2 · how to find part zero cnc

3 · cnc zero point settings

4 · cnc router part zero position

5 · cnc part zero position

6 · cnc mill zero setting

7 · cnc mill reset zero point

Protect essential wiring connections in any home or workplace with durable junction boxes from Toolstation. Find electrical and lighting junction boxes in various amperages to suit different applications. We stock standard electrical .

part zero cnc machine location

CNC Machine Workpiece Zero: How to Set it Perfectly Every Time! In this comprehensive tutorial, we dive deep into the crucial process of setting the workpiec.

part zero cnc machine

Before moving and cutting a block, the CNC machine needs to know where to start, the start position is the part zero used in programming. In this article, here are three ways for how to set zero point in CNC or how to . 1. Using an Edge Finder. Using an edge finder is a common and effective method for setting Part Zero in a CNC router setup, especially on flat surfaces. This tool, essential for precision, helps accurately locate the edges .

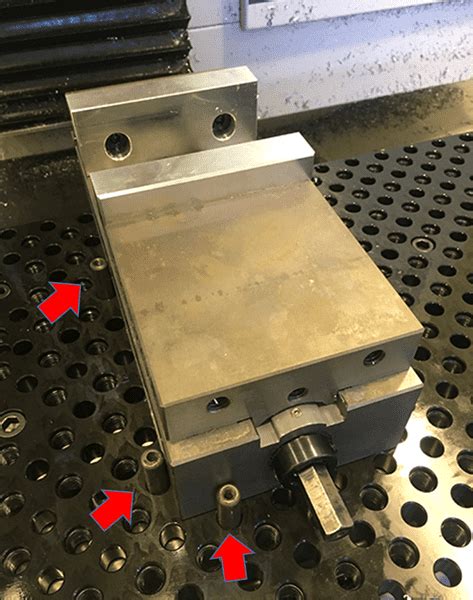

Method 1: Use an Edge Finder. Edge Finders are by far the most common way to find part zero, so we’ll start there. To use this method, put your part in the milling vise or . Work offsets are basically the stored location of your part in the machine. You use them to set the XYZ zero location when working in absolute positioning mode. There are multiple work offsets available.This article defines work zero, homing and how to use it. The Home position is a static position, this is set by using the homing switches installed on your machine. Work Zero refers to the position you want to start carving.

CNC Machine Training: This video discusses how to set up your material, zero out your machine and referencing your axes. By setting up your machine absolute zero it will allow you.

This video tutorial explains how to set up your CNC router bit start point, or zero point, for XYZ for your CNC router projects. To zero a CNC machine, follow these steps: Power on the machine and home all axes. Use a piece of paper to feel for the distance between the end mill and the workpiece. .

how to find part zero cnc

cnc zero point settings

general sheet metal south bend

Whether you’re using a high-end production CNC router or a DIY CNC router, establishing this point determines how effectively the subsequent cutting and shaping processes work. Especially for intricate designs, like those .

If the work part zero is not set correctly, the machine will incorrectly place the tool in relation to the part, resulting in incorrect cuts. Steps to Set Work Part Zero. Step 1: Clean the Part and Machine. Before you begin setting work part zero, you should clean the part and machine. Clean any debris or dirt from the machine and part using a .

Another reason why. If the relative position is not at 0.000 at machine reference, then when you set a tool, your tool offset may be wrong, hence your crash. Parameter 1201.2 will zero out your relative position to zero whenever you do a reference return in the Z axis. How to touch off lathe tools using Mach3 on a CNC lathe conversion.

On my old Makino with Fanuc 3000C control, we were given a fixed distance from the Z axis zero return position to the table. This value was used with G92 (as a POSITIVE value) to set an absolute zero on the machine table. If you part zero was, say, 5" above the table, then the G92 value would be 5" less than the fixed distance value. This video tutorial explains how to set up your CNC router bit start point, or zero point, for XYZ for your CNC router projects. You will learn how to set th.

@OnefinityCNC @MyersWoodshop I was gearing up for my first cuts today on the Myers threaded wasteboard. I really liked that on my last machine, and im not sure how i feel about the V2 concept. Anyways, not important. SO I homed the machine but then I couldn’t figure out how to set the middle of the board to be my zero. I tried hitting the 0 button next to the . Will Cut2D Pro then automatically start cutting at the top of the material and gradually work its way down to the bottom of the material (top of spoil board)? Thanks for the help. Top. IslaWW Vectric Wizard Posts: 1426 Joined: Wed Nov 21, 2007 11:42 pm Model of CNC Machine: CNC . is that you 1) Set Machine Bed in your design 2) You zero the Z . Because your home position (machine Z0) is = to your Z max soft limit, it is setting the alarm. Try to adjust your soft limits so they home position is within them. Maybe make your Z MAX_LIMIT = 0.1. If you don't have enough free travel to do that, you could adjust your homing position to give you the needed space.

Third, you need to work in positions all over the CNC’s bed so you’ll move the zero point often. Fourth, once you put all this together, there’s much to be gained if you can set origin . Hi, I am new to CNC milling and I have a Fanuc 3M controlled AccuMill from the 80’s. We have a person coming in this weekend to train us on CNCing but I was wondering if there is any material on the Internet on how to do the following things. Set tool compensations & offsets. Set part zero & Machine Zero.That is why all expensive industrial CNC machines automatically (no choice) Home the machine at startup. The CNC router hobbyist should also follow the same procedure. You should always send your CNC router to the "HOME" position ("Machine Zero" - X, Y, Z = 0, DRO Home button) after hitting the power button.

For #2, you've got to set your zero point manually. Homing the axis doesn't set the zero, nor is the "home" position for the axis necessarily where you want the zero point to be. (The limit switches are really more of just a safety net then anything else, to make sure you don't accidentally slam an axis into a hard limit.)Here’s a list of the required items and tools you’ll need to make this first part: A scrap piece of wood (at least 2 in. × 4 in. × 4 in.) 1/8 in. end mill ; 3/8 in. end mill ; Marker ; TTS Set Screw Holder: 3/8 in. (PN 31820) A PCNC 440, 770M, 770MX, 1100M, or 1100MX mill; Setting Up the Machine and Your Work. First, turn your machine on . CNC Machine Workpiece Zero: How to Set it Perfectly Every Time! In this comprehensive tutorial, we dive deep into the crucial process of setting the workpiec.

Some machines have a movable touch plate that can be placed either on top of of the spoilboard, or on top of the material being cut, with the Z-zero set accordingly in VCarve. It sounds like your machine has a fixed touch plate, aligned to the top of the spoilboard, in which case you'll always want to use the Machine Bed Z-zero setting in VCarve.

Zeroing your CNC in Theory & Practice. Updated 4 years ago by George . After getting feedback from users who have purchased CNC's for the first time, we have found that that one of the most common stumbling blocks is .

Method 3: Pick a Fixed Location on Your Vise or Fixture. With the other two methods, you have to find part zero every time you drop a new workpiece onto the machine.You tell the machine where the part is by using datums. All you do is set the distance to the part from the machine reference (home) position. You will need to decide where on the part you want your datum before you create your Gcode program. Then, when you set up the machine to run the program you will position the datum on the raw stock in .

If you don't have limit switches, then homing with not work as you know. There is not a way to force set machine zero at the moment other than resetting the arduino. A soft reset will try to maintain current position. However I don't see an issue with havin to power cycle the arduino to do so. Work coordinates are a standard gcode. This article explains how to set the WORKSHIFT on a CNC Lathe. If you use a Fanuc control you will need to set the WORKSHIFT value. . The workshift is an adjustable figure that tells the control where the work zero is. . Once your workshift is set you are ready to prove out your part. You can test the workshift in MDI if you wish. T0101; The zero buttons here zero the G54 coordinates (or whatever other you might be in), but don't change the Machine coordinates, whether Auto Zero is checked or not. Originally Posted by Frogblender Currently, when starting Mach3.exe, it makes a stupid assumption: "mach3.exe is starting, therefore mill must be at 0,0,0" - even if it is not.

This is a walk through of how to set your work offset manually in Mach4 on your Avid CNC machine.-----Featured products:Mach4: https://www.avidcnc.com/mach.SETTING UP THE MACHINE AND YOUR WORK. 1. First, turn your machine on, and get ready to make some chips. 2. Verify that the machine can freely move to its reference position. Do this by referencing the Z-axis first by hitting REF Z in the PathPilot interface. Then .Vertical Mills ; VF Series; Universal Machines; VR Series; VP-5 Prismatic; Pallet-Changing VMCs; Mini Mills; Mold Machines; High-Speed Drill Centers; Drill/ Tap/ Mill SeriesWhich means you take the part out of the machine, then have to go through the same process to make some kind of fixture. The fixture needs to hold the now more complexly shaped part in a way that is as accurate as possible, as rigid as possible, but also doesn't damage the part. Then you can work on another side of the part.

I have two fences on my machine at X0 and Y0, both in machine coordinates. I turn on the machine and home it, and my fences are all set. I just place the part against the fences and hold it in place with CAM clamps. I never set offsets or zero the X and Y Axis, just place the part on the table and go.

cnc router part zero position

cnc part zero position

5 talking about this. We provide the right materials, at the right time, for your metal roofing or building project.

how do you set work part zero on cnc machine|part zero cnc machine location