how do parameters set on cnc affect manufacturing This comprehensive guide has provided an in-depth understanding of the essential CNC machine parameters. By optimizing these parameters, operators can achieve superior precision, . Sheet metal workers ensure you stay warm in the winter and cool in the summer by making, assembling or servicing the heating and cooling equipment in buildings. These tradespeople may.

0 · cnc parameters explained

1 · cnc parameters examples

2 · cnc parameter settings

3 · cnc machining parameters list

4 · cnc machining parameters explained

5 · cnc cycle parameters

6 · best cnc parameters

7 · 7 cnc parameters

$65.97

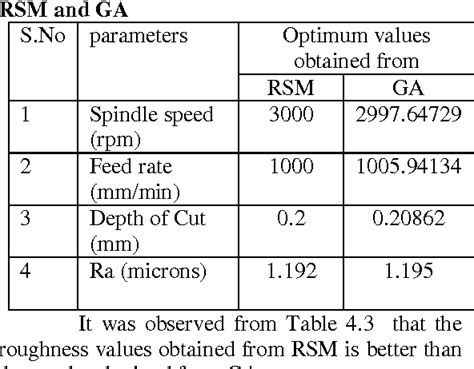

By comprehending the significance of spindle speed, feed rate, depth of cut, tool diameter, tool geometry, coolant and lubrication, machine rigidity, and the CNC control system, CNC .This comprehensive guide has provided an in-depth understanding of the essential CNC machine parameters. By optimizing these parameters, operators can achieve superior precision, .

By understanding the types of CNC machine parameters, the factors influencing parameter settings, the steps for setting them, the recommended parameters for different .In this comprehensive guide, we have explored the importance of CNC machine parameters in achieving optimal performance and efficiency. Understanding and optimizing these parameters .The selection of appropriate machining parameters is critical to achieving optimal results in terms of part quality, tool life, and production efficiency. Machining parameters depend on factors such as the material being machined, the .

Machining parameters for milling operations will influence the efficiency and quality directly, so it’s necessary for optimization of CNC milling parameter, definition of each parameter, selection . There are certain parameters that every CNC user should know related to safety, efficiency and simplifying machine usage. All CNCs have similar parameter settings. Rolling .

Understanding the key parameters of a CNC machine is essential for maximizing efficiency, precision, and productivity. Whether you’re a seasoned machinist or new to CNC machining, .

The greatest beauty of the CNC machine tool is its precision. Because computers do the cutting instead of humans, these machines can achieve a much higher accuracy. The ability to meet stringent specifications makes CNC machining . The choice of material significantly impacts both the cost and the machining process in CNC manufacturing. Materials like stainless steel and titanium, which are harder and tougher, require more time and specialized tooling, thereby increasing costs. . Can the design of a part affect its CNC machining cost? . Set tolerances that ensure . The Flex Feed Gear parameters might not have been used originally too. Usually setting correct values to CMR, DMR, and Reference Count are all you need to do to make an axis, linear or rotary, work fine. Flex Feed Gear was implemented to allow weird mechanical ratios to be used. Rarely applies to "standard" setups.

WRT the parameters you listed in your first post, I have the following for #26: 00100000 I have the parameter list from Mori-Seiki, the Q95503A Parameter List both in Inch and Metric, and it says #26 = 01010000 My parameter list does not have #24 or #25 on it, but both on the control match what you posted.

You are not going to be able to set whatever ones you want. You also can NOT set all of the parameter bits =1. Activating bits is turning on options in the machine. If you do not have the hardware or your machine is not configured to support these options they will not work. You say that you are missing some that you had before.CNC turning machines play a crucial role in the manufacturing industry, allowing for accurate and efficient production of various components. However, to harness the full potential of these machines, proper set-up is essential. In this blog post, we will provide a comprehensive guide on how to set up a CNC turning machine.By following this comprehensive guide on how to set up a CNC milling machine, you will be well-equipped to start your machining journey. . CNC machining is a versatile manufacturing technology that can be used for a wide range of applications. Common examples include components for the aerospace, automotive, medical industries and etc . Manufacturing Today. CNC Machining . Fanuc 21i Parameters . Tried changing # 1300 with bit 2 at "1 " and set parameter 1327 and 1328 ... Did not work, values in 1327 1328 had no effect on travels. . in 1322, and 1323... Same result. Values in 1322 and 1323 had no effect on travels. 1320 and 1321 seem the only parameters that effect .

You don't need to do a grid shift, you need to use a different procedure to reset the axis. First look in parameter 1240. This should be the "reference positions". The numbers in this parameter are what the control sets to absolute .

I have seen a screw with .010" lost motion that repeats to .0001" because the scale controls this. If the lost motion is greater than a setting parameter then a servo disconnect happens. There is also a backlash comp for machines that don't utilize scales, but I would rather fix the problem rather than set the backlash comp. CNC machining is a versatile and precise method of creating parts and products from various materials. However, it can also be costly and time-consuming if not planned and executed properly. For example, a line of 43.489 length, Linear Interpolated in one axis (combination of X and C to give the appearance of one axis), at Diameter 90.0 the C Axis will move through 51.684deg. At Diameter 20.0, the C axis angular move will be 130.706deg. Because of this, an alarm is raised if the C Axis Feed exceeds a max value set in parameter.

2204.0 is 0. Turning it to 1 removes it from the display, which is what I may as well do if I can't get it to actually work. The machine's parameters say it does have spindle position coder (3001.2 = 1) and the manual says that if the bit is set to 1 and the machine doesn't see the signal from it, it will generate an alarm.

These programs, often in the form of G-code, are generated through CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. The CNC router interprets these instructions to execute precise cutting, milling, and carving operations. Here is a general step on how to set up a CNC router.

After I got them home at some point the 4020 lost it's parameters. . If that were the case the 6030 might run smoother even if the gains were set on the high side. Power to weight/rigidity ratio being lower on the 6030. . Register for the world’s largest manufacturing technology forum for free today to stay in the know. Learn more about . Introduction to CNC Machining of Complex Shapes. CNC machining has revolutionized the manufacturing industry by enabling the production of complex shapes with high precision and efficiency. This . Manufacturing Today. CNC Machining . Diagnostic Parameter loss . The 35 diagnostic parameters that I set the machine to (some I did not change): 401 10110001 402 10110100 406 10000111 . for your machine either being equipped with a transmission, or not equipped. So, you can see that the value of the parameter can have a drastic effect on .

It is crucial to set the appropriate spindle speed based on the material being machined and the desired cutting conditions. Understanding how spindle speed affects tool life, cutting forces, and surface finish is essential for achieving optimal results. . understanding the machine parameters in CNC machining is paramount for achieving optimal . How do Laser Parameters Influence Laser Cutting quality? The chosen of laser cutting parameters directly affect the laser cutting quality. Here’s how each parameter contributes to laser cutting quality: Power: Less power won’t be able to cut through sheets. In comparison, an overpowered laser will damage the material surface. It may be something as simple as changing the order of operations or a tool type. - worst case is that all have equal influence and you have to do a lot more testing and controlling to fix the issue. It all comes down to a well defined manufacturing process and the only way to get a good one is with proper testing.

The amount it will shift depends on how the offset parameter is set- whether to comp radius or diameter. Say you have a 10mm dia. end mill. If the parameter is set to comp radius, and you enter +.5 in the offset register, the machine will treat it as an 11mm dia. cutter. If your machine currently set tool life by the number of hours used, and you would rather have is set by the number of times the tool was called, you would look at bit #2. if it is set like 6800 00000000, then bit 2 is off, and tool life is determined by the number of times the tool is called. if it is 6800 00000100, then bit 2 is on (the bits . Discover why CNC machining parameters are crucial for achieving precision, extending tool life, improving surface finish, and reducing production costs. . These parameters directly affect cutting conditions, impacting performance, surface quality, tool longevity, and overall productivity. . In the world of modern manufacturing, precision .

cnc parameters explained

CNC system parameters are the soul of CNC machine tools, and the normal function of the software and hardware of CNC machine tools is set by parameters. The manufacturing accuracy of the machine tool and the accuracy recovery after maintenance also need to be adjusted by parameters, so the CNC machine tool without parameters is equivalent to a .

1. Understanding the Basics of CNC Machines . Brief history and evolution of CNC technology . Overview of different types of CNC machines . Importance of CNC machine parameters for optimal performance . 2. Key CNC Machine Parameters:\ a. Feed Rate and Speed . Definition and significance of feed rate and spindle speed . Factors affecting feed . Knowing (or suspecting) that a parameter affects a given issue is just the beginning of correcting the issue. You must be able to find the parameter in question. Most CNC manufacturers document related parameters in a group, but since there are so many of them, it still can be difficult to find the one that is related to your particular issue.CNC machining has become an integral part of various industries, as it offers precision, efficiency, and versatility when it comes to manufacturing custom parts and components. This manufacturing process has evolved from the numerical control (NC) machining process, which used punched tape cards to control machinery. CNC stands for Computer.

how to make a small metal lock box

how to make a plastic lid for a metal box

Choose from our selection of sheet metal tools, including over 1,300 products in a wide range of styles and sizes. In stock and ready to ship.

how do parameters set on cnc affect manufacturing|7 cnc parameters