additive manufacturing vs cnc machinng While both CNC machining and additive manufacturing are widely used in various industries, their applications differ depending on factors such as cost, materials, level of customization, and . The Wiegmann® six-by-six-by-four-inch, nongalvanized steel screw cover pull box is designed as a larger junction box and can house a large assortment of electrical devices. It features a gray enamel finish and is NEMA 3R rated.

0 · difference between cnc and am

1 · cnc machining vs am

2 · additive manufacturing vs cnc

The 200 D Heavy Metal Feeder holds 200LBS of feed and has a 30 ft. 360 degree range. It features a built in funnel to reduce feed waste and has a 12 piece powder coated leg kit. The digital power control unit allows for 4 feeding times and comes with a galvanized spinner plate.

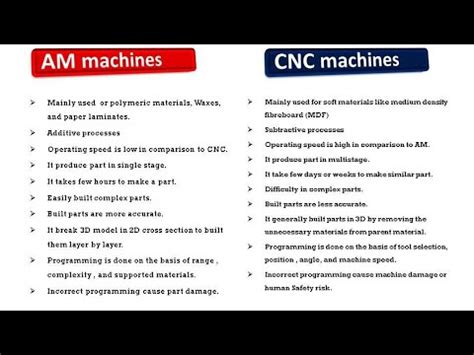

With Additive Manufacturing (AM) material shaping process can be long. AM allows for freedom of design and personalized production, while CNC Machining excels in precision and mass production.

The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while .Additive manufacturing allows for complex geometries and customization, while CNC machining offers high precision and speed. The choice between these techniques depends on factors . CNC machining is an ideal choice for manufacturing high-precision and high-quality parts, while additive manufacturing is suitable for manufacturing complex geometric shapes and small batch production.While both CNC machining and additive manufacturing are widely used in various industries, their applications differ depending on factors such as cost, materials, level of customization, and .

In this post, we will explore and compare two prominent manufacturing methods: Additive Manufacturing (AM) and CNC Machining. By assessing their key differences, advantages, and . Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time .

difference between cnc and am

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is .Additive manufacturing and CNC manufacturing are two popular production techniques that produce precise and functional metal parts fast and efficiently. Both are powerful and sophisticated manufacturing resources that bring any .With Additive Manufacturing (AM) material shaping process can be long. AM allows for freedom of design and personalized production, while CNC Machining excels in precision and mass production.

Unlike additive manufacturing, CNC machining is a subtractive manufacturing method that starts with a block of raw material and removes it bit by bit using rotating tools until it achieves the desired shape. The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.Additive manufacturing allows for complex geometries and customization, while CNC machining offers high precision and speed. The choice between these techniques depends on factors such as the desired part characteristics, volume of production, lead time, and cost considerations. CNC machining is an ideal choice for manufacturing high-precision and high-quality parts, while additive manufacturing is suitable for manufacturing complex geometric shapes and small batch production.

While both CNC machining and additive manufacturing are widely used in various industries, their applications differ depending on factors such as cost, materials, level of customization, and projected production volume.

In this post, we will explore and compare two prominent manufacturing methods: Additive Manufacturing (AM) and CNC Machining. By assessing their key differences, advantages, and applications, we aim to provide a comprehensive understanding of these powerful technologies. Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time (see our blog post on this). In the past, metal AM processes were expensive and slow.Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes.Additive manufacturing and CNC manufacturing are two popular production techniques that produce precise and functional metal parts fast and efficiently. Both are powerful and sophisticated manufacturing resources that bring any design concept to life.

With Additive Manufacturing (AM) material shaping process can be long. AM allows for freedom of design and personalized production, while CNC Machining excels in precision and mass production. Unlike additive manufacturing, CNC machining is a subtractive manufacturing method that starts with a block of raw material and removes it bit by bit using rotating tools until it achieves the desired shape.

The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.Additive manufacturing allows for complex geometries and customization, while CNC machining offers high precision and speed. The choice between these techniques depends on factors such as the desired part characteristics, volume of production, lead time, and cost considerations. CNC machining is an ideal choice for manufacturing high-precision and high-quality parts, while additive manufacturing is suitable for manufacturing complex geometric shapes and small batch production.While both CNC machining and additive manufacturing are widely used in various industries, their applications differ depending on factors such as cost, materials, level of customization, and projected production volume.

In this post, we will explore and compare two prominent manufacturing methods: Additive Manufacturing (AM) and CNC Machining. By assessing their key differences, advantages, and applications, we aim to provide a comprehensive understanding of these powerful technologies.

Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time (see our blog post on this). In the past, metal AM processes were expensive and slow.Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes.

cnc machining vs am

No more hunting for drivers and software to recognize your controller. Easily play 5000+ controller-enabled Steam games and enjoy full Steam Big Picture Mode and Steam Link support, right out of the box.

additive manufacturing vs cnc machinng|additive manufacturing vs cnc