sheet metal parts working Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. We offer 3D visualized Design for Manufacturability (DFM) feedback to help you manage project costs and . Manufacturer Part Number* UPC* * Item/UPC/Part # search method .

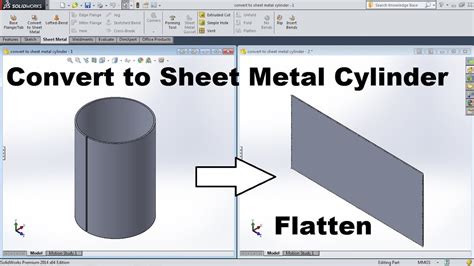

0 · solidworks convert to sheet metal

1 · sheet metal parts near me

2 · sheet metal dimensioning standards

3 · automotive sheet metal near me

4 · aftermarket sheet metal parts

5 · aftermarket sheet metal car parts

6 · aftermarket sheet metal body parts

7 · aftermarket auto sheet metal parts

We provide the industry's top solutions of heavy-duty storage cabinets, lockers, and workstations–all backed by 10-99 year warranties. Invest in the best for your facility and staff, keeping what's important safe and secure in lasting products built .

Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. We offer 3D visualized Design for Manufacturability (DFM) feedback to help you manage project costs and .

cnc aluminum miling parts

This complete guide’ll walk you through the basics of sheet metal fabrication and provide all the information you need to get started. From understanding the materials and processes involved to tips on finding the right .As sheet metal parts are fabricated from one sheet of metal, the part must maintain uniform wall thickness throughout. We recommend a sheet metal thickness range between 0.5-10 mm (0.02-0.394 in) for laser cutting and 0.5-6 .Looking for Sheet Metal Parts for your automotive? Then shop at 1A Auto for aftermarket, replacement Sheet Metal for many cars, trucks and SUVs, at a great price. Visit us online or call 888-844-3393 and order your car or truck Sheet Metal Part today!

Our online sheet metal fabrication service can ship custom sheet metal parts and assemblies in as fast as 1 day. Request a quote today to get started. . How Does Sheet Metal Fabrication Work? During the sheet metal fabrication process, . Recommended for: Advanced Sheet Metal Workers Ultimate Sheet Metal Fabrication by Timothy Remus is a great book to pick up if you would like to learn more about customizing sheet metal parts for automotive restoration and similar projects.. The author, along with other experts in the sheet metalworking field, describes how to build your own sheet metal . The term “sheet metal processing” covers a large number of manufacturing processes. Basically, the word sheet metal working refers to the manufacture of products, components and parts made of metal. In addition to welding, cutting and bending, the processes of sheet metal processing also include punching, forming, rolling and joining.

3. Sheet metal is a metal formed into thin and flat pieces. It is one of the fundamental forms used in metalworking, and can be cut and bent into a variety of different shapes. Countless everyday objects are constructed by this material. Thicknesses can vary significantly, although extremely thin sheets are considered as foil or leaf, and sheets thicker .

To flatten a body, do one: In the FeatureManager design tree, select the part and click Flatten (Sheet Metal toolbar).; In the cut list, right-click the body and click Flatten.; In either the FeatureManager design tree or the cut list, right-click the Flat-Pattern feature for the part and click Unsuppress.; To return the part to its bent state:

Table of Contents. 1 5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. 1.0.1 1. List part numbers, not just the part name; 1.0.2 2. Use the exact hardware name when possible; 1.0.3 3. Provide details for revision control

Welding is only required when a product consists of not one but two or more individual parts. Selection of Sheet Metal Fabrication Materials. . Because of the wide variety of subtleties and methods involved, working with a qualified metal fabricator on every job is essential. Since you have a basic understanding of sheet metal design, you .There were loads of simple sheet metal parts all over the machine, covering this and that. Our supplier has already been working with us for decades at that point, so all we really did was the exterior dimensions of the sheet metal, and the call-outs for thru/countersunk holes. . we work with a local sheet metal shop to make our sheet metal .When working in sheet metal, many users create parts by building, or layering tabs and flanges to achieve the desired result. This takes time and clicks . Using traditional modeling methods, sheet metal parts are modeled using standard feature trees and ordered lists of features. But there’s a faster, easier way.

Drawings of sheet metal parts can also contain views of the bent sheet metal part. Creating Sheet Metal Flat Pattern Configurations. You can create a configuration in a sheet metal part that shows the flattened part. . Available for all document types. Options vary depending on whether you are working with a part, assembly, or drawing.usually performed as cold working Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick Plate stock > 6 mm thick . , good dimensional accuracy, good surface finish, economical mass production (low cost). Cutting, bending, drawing. PARTS MADE BY SHEET METAL FORMING •Car bodies •Aircraft fuselages •Trailers •Office furniture appliances •Fuel .

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .Drawings of sheet metal parts can also contain views of the bent sheet metal part. Creating Sheet Metal Flat Pattern Configurations. You can create a configuration in a sheet metal part that shows the flattened part. . Available for all document types. Options vary depending on whether you are working with a part, assembly, or drawing. However for designers working on large parts with relatively low quantities (<10k) most sheet metal parts will be stamped or cut using CNC presses or lasers then formed on semi-automated brakes. This is because the . It does work—if the design does not have any bend along this area. But even then, the process requires an experienced fabricator. Solution 2: Software and Custom Sheet Metal Dies . To ensure precision bends in sheet .

Page 2 : 100, , , , sheet Metal Working 117, ¢ Production rates are rapid. Formin, , 8 Speeds can run as hi, average of 50 to 100 f¥/imin for m igh as 300 ft/min for some shapes and, , Ost applications., e The low labour cost and the savings in material cost, quantities are large enough to Pay off the initial tooling a, Disadvantages of Sheet Metal Forming are—, , provide .

If we’re working with a tolerance of +/- 0.005” and the sheet thickness is 0.056,” we’ve already lost 30% of our allowable tolerance before we start. . our team has decades of experience designing and making precision sheet metal parts. We know how to accommodate for tolerances of formed features and added features.

solidworks convert to sheet metal

The remaining 80% of the articles uses just the 20% of the sheet metal: these are parts with smaller production runs, lower quantities and higher variability where working from sheets is preferable. Sheet metal working - Download as a PDF or view online for free. . sheet-metal parts offer the advantages of light weight and versatile shape. However, the term press working or press forming is used commonly in industry to describe general sheet-forming operations, because they typically are performed on presses. Sheet metal working 12/31 . A Sheet Metal Worker, or Sheet Metal Technician, works with thin sheets of metal to produce and install various types of products. On a typical Sheet Metal Work job description, their listed duties may include measuring and marking raw materials, cutting sheet metal to desired sizes using specialized equipment and fastening sheet metal into place via soldering, .

2. Sheet Metalworking Defined Cutting and forming operations performed on relatively thin sheets of metal Thickness of sheet metal = 0.4 mm (1/64 in) to 6 mm (1/4 in) Thickness of plate stock > 6 mm Operations usually performed as cold working ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e different sheet metal parts in terms of . are incapable of meeting the mass production strategies as well as the processing and the working requirements of sheet metal products compared to deep . We compiled a list of 3D CAD programs that are free for most purposes and work for sheet metal design. If you're looking for a great 3D CAD program for personal, hobby, or even professional use, start below: FreeCAD. . As mentioned, it's 2D, so you'll have to know some in's and out's about design sheet metal parts. USER MANUAL GETTING STARTED .Metal Worker VS. Metal Fabicator Sheet metal work and metal fabrication are two interconnected yet distinct professions within the metalworking industry. While both involve working with metal materials, there are significant differences in their roles, responsibilities, tools, and areas of expertise. This article explores the distinctions between a sheet metal worker and a metal .

Single point incremental forming is a novel sheet metal forming process that crafts 3D shapes out of sheet metal using layerwise deformation of the metallic sheet with a simple tool, which is typically cylindrical with a hemispherical ball-end. In this work, a combination of intelligent clamping and toolpath strategies was used to manufacture tunnel-shaped parts using .

sheet metal parts near me

Our CNC machining services enable you to create custom stainless steel parts for many applications across industries such as energy, medical technology, agricultural, industrial automation, machinery, robotics and construction.

sheet metal parts working|sheet metal dimensioning standards