how to strengthen sheet metal parts $123.99 Can you post a photo of the label on the transformer? @ThreePhaseEel i edited my post. This is the only label i can find on it. So, you want to have an outlet wired downstream of this box, on the same circuit as the transformer, right? Can you get us a photo of the inside of the box (with the breaker off, of course)?

0 · sheet metal strengthening

1 · how to stiffen sheet metal

2 · how to make sheet metal better

3 · how to improve sheet metal parts

4 · how to improve sheet metal

5 · how to do sheet metal

6 · diy sheet metal repairs

7 · best way to strengthen sheet metal

Cutting processes are those in which a piece of sheet metal is separated by applying a great enough force to caused the material to fail. The most common cutting processes are performed by applying a shearing force, and are therefore sometimes referred to as shearing processes.

Bead rolling adds strength and design features to sheet metal by creating raised or indented lines, known as beads, along the surface. This technique is often employed for stiffening panels or adding decorative elements to automotive parts.

3.999.979.97.99

sheet metal strengthening

how to stiffen sheet metal

7 Ways to Improve Sheet Metal Parts. Consider material and finishing options along with design elements like bends, reliefs, holes, and slots when developing sheet metal components. Before diving into the details of sheet metal . For sheet metal parts to be durable and reliable, metal strengthening, sometimes referred to as stiffening, is essential. It entails incorporating structural support to stop pieces from warping and failing under . Bending, holes and slots, and stretching are just a few of the key characteristics of a well-designed, strong sheet metal part that 3D SheetMetal Creator can help you easily achieve. Let’s get into more details below. Bends .Using traditional modeling methods, sheet metal parts are modeled using standard feature trees and ordered lists of features. But there’s a faster, easier way. Synchronous technology .

Available sheet metal hardware are self-clinching nuts, self-clinching standoffs, flush-head stud, thin sheet non-flush stud and more. Of course, you can combinate all these ways, which allow you to make a strong . From hydroforming to plasma cutting, from metal shearing to metal spinning, fabricators use a dizzying array of common and not-so-common processes to transform raw . Well, with eight key strategies, you can enhance your sheet metal parts and increase their strength, durability and performance. In this article, we'll explore how heat treatment, cold working, cold rolling and other processes .

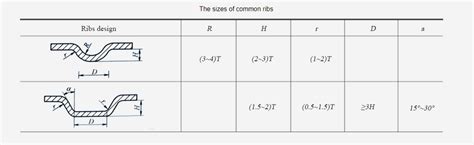

Among the many ways to reinforce sheet metal parts, bending can help them become stronger. You can bend the edges of thin strips of metal to change their. . You can bend the edges of thin strips of metal to change their. E-posta: [email protected] Hizmetler. CNC İşleme; 3D Baskı .The flat sheet metal part is not strong enough, as it lacks of the structural integrity. In addition, the flat sheet metal part is easy to bend and deform under pressure. Therefore, the flat sheet metal design should be avoided. Adding ribs, flanges, or hems to sheet metal parts are suggested to bolster the sheet metal parts.

how to make sheet metal better

Outdoor Wall Mounted Bike Rack. Type: Standard Bicycle Weight and efficiency constraints may also rule out the other simple way of making sheet metal parts stronger: increasing the thickness of base material used. Fortunately, there are a number of ways to increase the structural strength of flat sheet stock without adding gussets or increasing the weight of the product. Applying tension to a sheet .

However, because the sheet metal parts are relatively thin, there are often challenges related to rigidity and strength under certain conditions. This article will introduce the 4 main design tips to enhance the strength (rigidity) of sheet metal components. . Adding Tapers to the Bends to Strengthen Sheet Metals. Choosing the right hardware and designing sheet metal to fit it is one of the most critical aspects of sheet metal manufacturing.Designing parts correctly for hardware can be difficult – countersinking material for flush rivets, picking the right depth of threading, ensuring the part is actually thick enough to accommodate screws. A few methods are shown to stiffen up projects in sheet metal In this blog I want to discuss tips for designing stronger sheet metal parts using the tools in 3D SheetMetal Creator role. 3D SheetMetal Creator is a fully browser-based solution that includes the xSheetMetal app with purpose-built tools for sheet metal design, in addition to other apps and features for storing, managing and collaborating on .

steel rocket ammo box

Adding an angle bend to your design can strengthen your sheet metal parts. If you do not want a 180° bend, you can add an angle bend to add strength to your sheet metal. This simple act of bending will help prevent that part from twisting out of shape. Add Strength to Sheet Metal Part with Welding. Sheet metal fabrication for chassis, tanks, enclosures, and other sheet metal parts. Last updated on February 23rd, 2024 at 08:51 am. Forming deep boxes or U shapes in sheet metal isn’t as straightforward as it seems. Using a regular press brake to accomplish a complex bend often results in one of the metal legs twisting out of control—or . Home / Rethinking Parts In Sheet Metal Design: The Angle Bracket. Rethinking Parts In Sheet Metal Design: The Angle Bracket . Adding a front flange leg to adjust the lower mounting pad will bridge the sides of the bracket and help strengthen the part. (first view) Figure 4. Adding a front flange leg to adjust the lower mounting pad will .What is nesting in sheet metal parts manufacturing? Nesting also refers to the process of minimizing the waste of raw material. It is a process of creating the right cutting patterns to make as many useful parts as possible. These efforts can be applied to additive manufacturing as well (e.g. 3D printing). How to strengthen sheet metal parts?

Sheet metal parts make up a variety of essential items in our daily lives. From the frames that support our homes to the cars we drive, sheet metal is often. ISO 9001 Certified. . Heat treatment can drastically strengthen sheet metal parts by altering their microstructure, thus increasing the part's load-bearing capacity and durability. .Tips and Tools for Strengthening Your Sheet Metal Parts Bending, holes and slots, and stretching are just a few of the key characteristics of a well-designed, strong sheet metal part that 3D .bearing in the lower assembly. Doing so creates the stiffening rib that can be used to strengthen the sheet metal. The shape of the form is the result of programs created in the punch press programming system. Beaded Emboss Embossing operations are commonly used in sheet metal and vary in purpose and function; one such function is to add .

Among the many ways to reinforce sheet metal parts, bending can help them become stronger. You can bend the edges of thin strips of metal to change their. Email: [email protected] Italian We have sheetmetal parts that we work on for a company, the model files are in the IGES format.So they come into SW08 as an Imported object. Many of the 90° bends in the parts have strengthening ribs in them going through the corner and SW08 will not or does not allow the part to be flattened or unfolded.

Among the many ways to reinforce sheet metal parts, bending can help them become stronger. You can bend the edges of thin strips of metal to change their . You can bend the edges of thin strips of metal to change their. Email: [email protected] Servicii. Prelucrare CNC; Imprimare 3D; Turnarea în vid; Partea de tablă . Among the many ways to reinforce sheet metal parts, bending can help them become stronger. You can bend the edges of thin strips of metal to change their E-post: [email protected] The difference is that with sheet metal edge rolling, you put a small piece of metal wire near the edge of the panel and you fold the edge of the metal over it. Rolling sheet metal edges with wire strengthens the panel in two ways that ordinary sheet metal bending doesn’t. One is that, by metal being folded over itself, it has doubled in . Filler rods help to reinforce and strengthen the corners. We melt them to the appropriate temperature before attaching them to the base of the part. Steel or stainless steel. . Corner construction plays a vital role in ensuring the durability and strength of sheet metal parts. When corners are not properly prepared for welding, it can lead to .

As such, excessive bends may cause the sheet metal to crack instead of strengthening it. There are several ways of bending sheet metal. The simplest involves clamping the stainless steel metal on a table and using your weight to bend it over. Alternatively, you can use a body hammer and the edge of a dolly to fold the metal to create a firmer bend. Instead, we can make thin sheet metal sturdier without adding weight to the part. You’ll save money the vast majority of the time, and you’ll get a part that’s lightweight and strong. 3 Ways to Get Sturdier Flat Sheet Metal Parts. There are three approaches we use at Ameritex to make flat sheet metal parts more rigid without adding weight.Flanges make the process of creation of a sheet metal part quick and convenient. In the course of conceptualizing a flange, the following should always be taken into consideration – Flange width must never be less than four times the thickness of the sheet metal. On failing to do so, the tool of choice will leave a mark on the sheet metal .

how to improve sheet metal parts

Among the many ways to reinforce sheet metal parts, bending can help them become stronger. You can bend the edges of thin strips of metal to change their E-mail: [email protected] Embossing operations are commonly used in sheet metal and vary in purpose and fu nction; one such function is to add strengthening ribs. A common way to add strength to a sheet metal part is to introduce a bend or beaded emboss. As the material is deformed, the effective material thickness increases and the material becomes stronger.

Among the many ways to reinforce sheet metal parts, bending can help them become stronger. You can bend the edges of thin strips of metal to change their. E .

The main difference between NC and CNC is that CNC is computer controlled, while NC is controlled by prerecorded information and punched tape. Besides CNC being more advanced and NC being more rudimentary, there are lots of .

how to strengthen sheet metal parts|how to do sheet metal