cnc machine milling pdf By combining the elements of CNC lathe machines with milling tools, mill-turning CNC offers high levels of accuracy and geometric versatility, making it great for creating parts with loose . Ford does refer to it as the Smart Junction Box in the TSB and in the Ford Service Manual Wiring Diagrams.

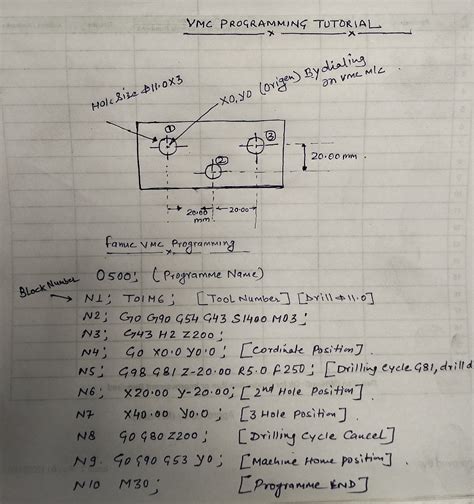

0 · cnc milling programming PDF

1 · cnc milling machine specification

2 · cnc machining handbook PDF

3 · cnc machine tool design PDF

4 · cnc machine manual PDF

5 · cnc machine maintenance manual PDF

6 · cnc machine drawing PDF

7 · cnc machine basic knowledge PDF

Junction boxes join multiple wires and are used in residential and commercial spaces for organization and code compliance. Choosing the Right Electrical Box for Your Project. Selecting the appropriate electrical box depends on several factors, including construction, wiring method, devices, location, and safety. Type of Construction

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the .

Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC .Milling: Rotating a cutting tool to bring it into contact with a stationary workpiece. Milling machines are used for milling. Drilling: Creating, or refining, holes by bringing a rotating cutting tool into .By combining the elements of CNC lathe machines with milling tools, mill-turning CNC offers high levels of accuracy and geometric versatility, making it great for creating parts with loose .

Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC .

The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining .CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically .A CNC milling machine consists of the machine base and moving axes, a computerized controller, and some form of spindle to rotate the cutter or part. These machines are run from data either .

Featuring hundreds of color images and schematic diagrams, CNC Handbook explains machining fundamentals and shows you how to build and safely operate fully automated, technically sophisticated mechatronic equipment.using this course have been taught to set up, program, and operate a CNC mill in less than 24 hours of combined classroom/lab time ; including instruction in HSMWorks.

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.

Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC and HMC) • ATC types: carousel-type and swing-arm-typeMilling: Rotating a cutting tool to bring it into contact with a stationary workpiece. Milling machines are used for milling. Drilling: Creating, or refining, holes by bringing a rotating cutting tool into contact with the workpiece.By combining the elements of CNC lathe machines with milling tools, mill-turning CNC offers high levels of accuracy and geometric versatility, making it great for creating parts with loose rotational symmetries, such as camshafts or centrifugal compressors.Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC and HMC) • ATC types: carousel-type and swing-arm-type

The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame) CNC fabrication machines (sheet metal punch press,

cnc milling programming PDF

CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. • The development of NC machine tools started from a task supported

A CNC milling machine consists of the machine base and moving axes, a computerized controller, and some form of spindle to rotate the cutter or part. These machines are run from data either programmed in by hand, or created by a CAD/CAM Featuring hundreds of color images and schematic diagrams, CNC Handbook explains machining fundamentals and shows you how to build and safely operate fully automated, technically sophisticated mechatronic equipment.using this course have been taught to set up, program, and operate a CNC mill in less than 24 hours of combined classroom/lab time ; including instruction in HSMWorks.

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.

Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC and HMC) • ATC types: carousel-type and swing-arm-typeMilling: Rotating a cutting tool to bring it into contact with a stationary workpiece. Milling machines are used for milling. Drilling: Creating, or refining, holes by bringing a rotating cutting tool into contact with the workpiece.By combining the elements of CNC lathe machines with milling tools, mill-turning CNC offers high levels of accuracy and geometric versatility, making it great for creating parts with loose rotational symmetries, such as camshafts or centrifugal compressors.Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC and HMC) • ATC types: carousel-type and swing-arm-type

The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame) CNC fabrication machines (sheet metal punch press,CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. • The development of NC machine tools started from a task supportedA CNC milling machine consists of the machine base and moving axes, a computerized controller, and some form of spindle to rotate the cutter or part. These machines are run from data either programmed in by hand, or created by a CAD/CAM

cnc milling machine specification

For instance, vintage plastic tool boxes that are light but have short life sells for way less than the beautifully crafted, durable wooden antique chests. A plastic vintage tool box, generously, sells for around $5 to $20, whereas antique wooden ones start from $100.

cnc machine milling pdf|cnc machine basic knowledge PDF