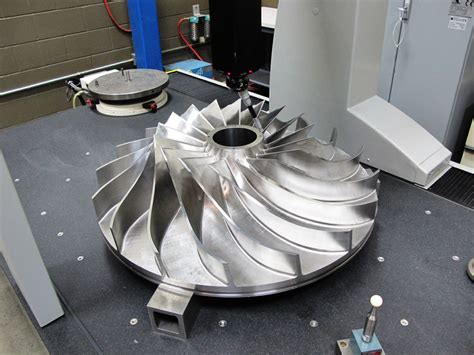

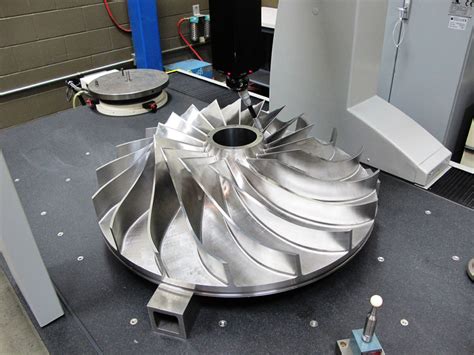

5 axis cnc impeller machining Impeller 5-axis CNC machining offers a range of benefits that directly translate into improved impeller performance and manufacturing efficiency: Unparalleled Precision: The multi-axis capability of 5-axis CNC machining enables the production of impellers with intricate designs and tight tolerances. Utah metal fabrication and machine work will help you get the job done easier and with a greater eye on safety. We are located near Centerville in beautiful West Bountiful Utah. Our satisfied customers are from all across this great state.

0 · five axis cnc machining

1 · 5 axis impeller machining

2 · 5 axis cnc impeller

Contur is the only cabinet company in North America that produces a curved double-walled all-metal door and we have the patents to prove it. Stylish yet tough, our cabinets will last you a lifetime. Choose from one of our licensed brands or, have us build a cabinet set custom-made to your specifications.

Impeller 5-axis CNC machining offers a range of benefits that directly translate into improved impeller performance and manufacturing efficiency: Unparalleled Precision: The multi-axis .

Manufacturing impellers on a 5-axis CNC mill offers unparalleled precision, .Here, we’ll discuss the 5 axis CNC machining of impeller: why use it, challenges and solutions during machining, and what you should consider in the machining process.Impeller 5-axis CNC machining offers a range of benefits that directly translate into improved impeller performance and manufacturing efficiency: Unparalleled Precision: The multi-axis capability of 5-axis CNC machining enables the production of impellers with intricate designs and tight tolerances.Here, we’ll discuss the 5 axis CNC machining of impeller: why use it, challenges and solutions during machining, and what you should consider in the machining process.

In this article, we will explore what 5-axis impeller machining involves, its advantages, challenges, and best practices for achieving optimal results. What is 5-Axis Machining? 5-axis machining refers to a computer numerical controlled (CNC) machining process that utilizes five different axes to manipulate the movement of the cutting tool.Revolutionary DMU 5 axis CNC machines and Wire EDM services allow for faster, more accurate construction of impeller. Our fast turnaround time coupled with consistent accuracy makes the production of even the most precision-dependent components a breeze.

WHY CHOOSE 5 AXIS CNC ROUTER FOR IMPELLER MACHINING? Today, a 5-axis CNC router is the only method to solve the machining of the impeller, blade, Marine prop, hefty generator rotor, wind turbine blades, large diesel engine crankshaft and so on.Manufacturing impellers on a 5-axis CNC mill offers unparalleled precision, efficiency, and versatility. The advanced capabilities of 5-axis CNC milling enable the production of impellers with intricate blade profiles, complex geometries, and exceptional dimensional accuracy.

Check out how our 5-axis CNC machine create an impeller. During the machining, simultaneous 5-axis machining technology is applied.-----.

5-axis CNC machines facilitate more precise fabrication of impellers. Our rapid turnaround time, combined with consistent accuracy, streamlines the production of even the most precision-critical components. Five-axis machining is an advanced Computer Numerical Control technology with high precision and dedication to machining complex surfaces. The impeller is a part that is usually produced using 5-axis machining, what challenges are there, and how to solve them? Using five-axis impeller rough machining mode allows for five-axis rough machining of impellers, achieving uniform material removal and smoother machining trajectories, thereby enhancing machining efficiency.

Impeller 5-axis CNC machining offers a range of benefits that directly translate into improved impeller performance and manufacturing efficiency: Unparalleled Precision: The multi-axis capability of 5-axis CNC machining enables the production of impellers with intricate designs and tight tolerances.Here, we’ll discuss the 5 axis CNC machining of impeller: why use it, challenges and solutions during machining, and what you should consider in the machining process. In this article, we will explore what 5-axis impeller machining involves, its advantages, challenges, and best practices for achieving optimal results. What is 5-Axis Machining? 5-axis machining refers to a computer numerical controlled (CNC) machining process that utilizes five different axes to manipulate the movement of the cutting tool.Revolutionary DMU 5 axis CNC machines and Wire EDM services allow for faster, more accurate construction of impeller. Our fast turnaround time coupled with consistent accuracy makes the production of even the most precision-dependent components a breeze.

WHY CHOOSE 5 AXIS CNC ROUTER FOR IMPELLER MACHINING? Today, a 5-axis CNC router is the only method to solve the machining of the impeller, blade, Marine prop, hefty generator rotor, wind turbine blades, large diesel engine crankshaft and so on.Manufacturing impellers on a 5-axis CNC mill offers unparalleled precision, efficiency, and versatility. The advanced capabilities of 5-axis CNC milling enable the production of impellers with intricate blade profiles, complex geometries, and exceptional dimensional accuracy.Check out how our 5-axis CNC machine create an impeller. During the machining, simultaneous 5-axis machining technology is applied.-----.5-axis CNC machines facilitate more precise fabrication of impellers. Our rapid turnaround time, combined with consistent accuracy, streamlines the production of even the most precision-critical components.

Five-axis machining is an advanced Computer Numerical Control technology with high precision and dedication to machining complex surfaces. The impeller is a part that is usually produced using 5-axis machining, what challenges are there, and how to solve them?

five axis cnc machining

3d stone cnc router machine factories

Blackbox Vacuum Solutions is the industry standard in single phase vacuum holding and offers three sizes of vacuum pumps to best fit your need: The Hurricane, Cyclone, and Storm. The .

5 axis cnc impeller machining|5 axis cnc impeller