cast cnc machined parts With CNC machining, you have the advantage of ordering parts as you need them, avoiding the risk of overproduction and excess inventory. In contrast, if you anticipate high demand and are transitioning into production, casting becomes a good choice. ERP software can significantly improve production efficiency in metal fabrication by providing real-time visibility into production processes, inventory .

0 · what is cnc machining

1 · what is a machined casting

2 · prototype die casting vs cnc

3 · metal casting vs cnc machining

4 · machined casting process

5 · cnc casting vs die casting

6 · casting vs cnc

7 · casting process vs cnc process

Electrical boxes made of metal typically require longer screws than electrical boxes made of plastic. It is important to use the correct size of screws when securing an electrical box. Screws that are too small will not be able to hold the box securely in place, and this could lead to the box coming loose and causing an electrical hazard.

With CNC machining, you have the advantage of ordering parts as you need them, avoiding the risk of overproduction and excess inventory. In contrast, if you anticipate high demand and are transitioning into production, casting becomes .

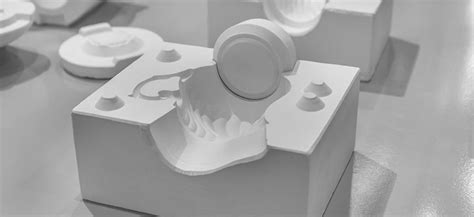

With CNC machining, you have the advantage of ordering parts as you need them, avoiding the risk of overproduction and excess inventory. In contrast, if you anticipate high demand and are transitioning into production, casting becomes a good choice.But have you ever considered CNC machining a part that you usually cast? Or are you considering which method is best to manufacture your design? This article will discuss the two manufacturing processes and the advantages and disadvantages of each.From electronic housings to bladed vanes and everything in between, Sycast delivers the highest quality CNC-machined components. 4 & 5-axis machining centers; CNC lathe / turning; Aerospace Inspection Room Learn More A machined casting is a part that was first cast into a semi-finished product, then finished with precision CNC machining. You can produce the initial castings using one of several casting methods, such as die casting, investment casting, or sand casting.

We provide cost-effective solutions to short run production for all non-die cast CNC machined parts. PHB Machining is a high capacity, 158,000 sq. ft. facility located next to the die casting plant. We work with many outside vendors to source a variety of different materials for non-die cast CNC machined products.Numco USA offers complete, turnkey domestic and offshore sourcing for your metal casting project, from the manufacture of the raw casting itself to additional precision machining services to plating, powder coating, and e-coating. Working from your designs, we will deliver custom metal castings that meet or exceed your expectations.

The good news is that you can get your parts faster simply by switching from cast parts to machined billets (aka “hogouts”). At Moseys, we not only deliver machined parts up to 90 days faster than you’ll receive most cast parts but also ensure exceptional quality unmatched by most casting processes.Explore the key differences between CNC machined and cast aluminum, including precision, cost-effectiveness, and ideal applications for each. Learn which method suits high-precision, custom projects versus large-scale, efficient production.

Precision Cast and Forge is your source for domestic and offshore high quality and affordably priced finished castings, forgings, and machined components.

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This technique is particularly well-suited for mass production of intricate and complex parts with tight tolerances. Here are some key aspects of die casting:With CNC machining, you have the advantage of ordering parts as you need them, avoiding the risk of overproduction and excess inventory. In contrast, if you anticipate high demand and are transitioning into production, casting becomes a good choice.But have you ever considered CNC machining a part that you usually cast? Or are you considering which method is best to manufacture your design? This article will discuss the two manufacturing processes and the advantages and disadvantages of each.

From electronic housings to bladed vanes and everything in between, Sycast delivers the highest quality CNC-machined components. 4 & 5-axis machining centers; CNC lathe / turning; Aerospace Inspection Room Learn More A machined casting is a part that was first cast into a semi-finished product, then finished with precision CNC machining. You can produce the initial castings using one of several casting methods, such as die casting, investment casting, or sand casting.We provide cost-effective solutions to short run production for all non-die cast CNC machined parts. PHB Machining is a high capacity, 158,000 sq. ft. facility located next to the die casting plant. We work with many outside vendors to source a variety of different materials for non-die cast CNC machined products.Numco USA offers complete, turnkey domestic and offshore sourcing for your metal casting project, from the manufacture of the raw casting itself to additional precision machining services to plating, powder coating, and e-coating. Working from your designs, we will deliver custom metal castings that meet or exceed your expectations.

The good news is that you can get your parts faster simply by switching from cast parts to machined billets (aka “hogouts”). At Moseys, we not only deliver machined parts up to 90 days faster than you’ll receive most cast parts but also ensure exceptional quality unmatched by most casting processes.Explore the key differences between CNC machined and cast aluminum, including precision, cost-effectiveness, and ideal applications for each. Learn which method suits high-precision, custom projects versus large-scale, efficient production.Precision Cast and Forge is your source for domestic and offshore high quality and affordably priced finished castings, forgings, and machined components.

what is cnc machining

electrical isolation box

A variety of materials can be used to boost the tensile strength of concrete. They are classified as either primary reinforcement, such as steel rebar or welded wire fabric, or secondary reinforcement, which is used to minimize .

cast cnc machined parts|cnc casting vs die casting