formulas sheet metal layout fabrication To help you achieve the highest standard of fit and function, here's our top 5 sheet metal design formulas you need to consider for bending Metal box springs are typically louder than wood box springs. This is because the metal coils in metal box springs can squeak when people move around on them. However, some metal box springs have noise-reducing features, such as padding or fabric covering.

0 · y factor formula sheet metal

1 · sheet metal geometry

2 · sheet metal flat patterns

3 · sheet metal bending formula

4 · sheet metal bend angle formula

5 · osos formula sheet metal

6 · fabrication formula sheet metal

7 · air bending formula sheet metal

1101 NE Main St. Grimes IA 50111 (515) 986-4366 (515) 986-3373; www.exteriorsheetmetal.com

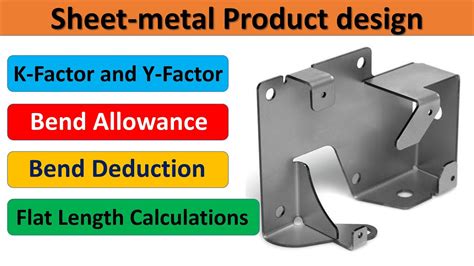

Layout and fabrication of these type of components are determined by well-established empirical formulas known as 'Bend Allowance' and 'Bend Deduction'. These formulas are in universal .

sheet metal forming process (stretch forming, spinning, rubber forming, and .Formulas: Bend Allowance (BA) – The amount of added to the sum of the two leg lengths to obtain the flat pattern length. Bend Deduction (BD) – The amount removed from the sum of the two flange lengths to obtain a flat pattern. .

Layout and fabrication of these type of components are determined by well-established empirical formulas known as 'Bend Allowance' and 'Bend Deduction'. These formulas are in universal . To help you achieve the highest standard of fit and function, here's our top 5 sheet metal design formulas you need to consider for bending

sheet metal forming process (stretch forming, spinning, rubber forming, and superplatic forming and diffusion bonding). Provides a useful die classification with 15 illustrations and .To save the cost of punching or drilling in a secondary operation the following formulas can be used to calculate the minimum distance required: For a hole < 1" in diameter the minimum . More Than One Sheet Metal Bending Formula. Press brake technicians can use various formulas to calculate bend functions. For instance, in this article we have used the following for outside setback: OSSB = [Tangent .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .

The primary goal of sheet metal layout is to accurately plan and create a flat pattern that can be bent, folded, or otherwise manipulated into the desired 3D shape. To achieve this, you must .

The following sections show the methods used to calculate flat patterns for brake-bent or die-formed sheet metal parts. The later sections describe the geometry and instructions for laying .Formulas For Sheet Metal Layout And Fabrication Formulas For Sheet Metal Layout And Fabrication Introduction In todays digital age, the availability of Formulas For Sheet Metal Layout And Fabrication books and manuals for download has revolutionized the way we access information. Gone are the days of physically flipping through pages and . More Than One Sheet Metal Bending Formula. Press brake technicians can use various formulas to calculate bend functions. For instance, in this article we have used the following for outside setback: OSSB = [Tangent .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed into the final

The Enigmatic Realm of Formulas For Sheet Metal Layout And Fabrication: Unleashing the Language is Inner Magic In a fast-paced digital era where connections and knowledge intertwine, the enigmatic realm of language reveals its inherentAny Impossibility in Shaping Metal Cass Nawrocki.2011-10-01 Advanced sheet metal fabrication techniques. Advanced Sheet Metal Fabrication Timothy Remus.2006 Sheet Metal Layout Leo A. Meyer.1961-01-01 Metal Fabricator's Handbook Ron Fournier.1990-08-02 Winner of the prestigious Moto Award for Best Technical How-to Book in 1984, the MetalFormulas For Sheet Metal Layout And Fabrication Leonard Jones,Otto Morse,Dan . Basic Sheet Metal Layout and Fabrication Leonard Jones,Otto Morse,Mid-America Vocational Curriculum Consortium,1983 Applied Metal BoatBuilding Methods D. Schaffer,2018-04-03 'Metal Fabrication' is the creation of metal structures by cutting and bendingFormulas For Sheet Metal Layout And Fabrication Handbook of Die Design Ivana Suchy.2006 This classic handbook provides the major formulas, calculations, cost estimating techniques, and safety procedures needed for specific die operations and performance . 'Sheetmetal Pattern Development' is a Metal Fabricators course in 'Precision Sheet Metal .

Metal Fabrication Robert L. O'Con,Richard H. Carr.1985 Sheet Metal Forming Taylan Altan,A. Erman Tekkaya.2012 Practical Sheet Metal Layout Richard S. Budzik.1971 04103-08 Intro to Sheet Metal Layout and Processes TG NCCER.2008-02-15 Mechanics of Sheet Metal Forming Jack Hu,Zdzislaw Marciniak,John Duncan.2002-04-17 The basic theory of sheet .Practical Sheet Metal Layout Richard S. Budzik.1987-07-01 The Calculation of Sheet Metal Work, for Students and Craftsmen Alfred Dickason.1950 Optimal Fixture Configuration Design for Deformable Sheet Metal Part Assembly Wenjia Cai.1996 Mechanics of Sheet Metal Forming Jack Hu,Zdzislaw Marciniak,John Duncan.2002-04-17 The 'Sheetmetal Pattern Development' is a Metal Fabricators course in 'Precision Sheet Metal Layout'. Teaching the theory, principles and application of these well-established Sheetmetal layout formulas to calculate the cut sizes, locations of bend lines and interior features demonstrated through the

sintex junction box price list

Content Sheet Metal Fabrication Design Guide Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a . handbook Soup io. Pipe Fabrication Formula Full Pdf Version How to Generate Flat Pattern or Fabrication Layout Marking of Fabrication Shapes or Sheet Metal Shapes. Fabrication Layout or Flat Pattern marking can be generated by using various ways that we are going to lean ahead. Use of Fabrication Layout Generating Method depends upon various factors or applications of shapes or accuracy of shapes.Formulas For Sheet Metal Layout And Fabrication Sheet Metal Fabrication Eddie Paul. In our mechanized day of mass production, the craft of hand-forming sheet metal into compound curves and dashing fins and fenders is fast becoming a lost art. Eddie Paul is a master at sheet metal fabrication (among other accomplishments), and in this book

fabrication industry. 'Applied Metal Boatbuilding Methods' - 'Sheetmetal Pattern Development' is a Metal Fabricators course in 'Precision Sheet Metal Layout'. Teaching the theory, principles and application of these well-established Sheetmetal layout formulas to calculate the cut sizes, locations of bend lines and interior features demonstrated .Fabrication Formulas. SHEET METAL LAYOUT AND FABRICATION tpub com Index sheetmetallayoutcalculator com April 21st, 2018 - Sheet Metal Layout Calculator Architectural Expansion Joints amp Layouts BOOT TEE Layout including Hole Layout Cone and .

y factor formula sheet metal

Read about different ways of grounding switches and outlets in metal and plastic electrical boxes.

formulas sheet metal layout fabrication|sheet metal geometry