why does outoor junction box have no holes The only mounting holes currently in the junction box are in the bottom of the box- there are none on its sides. It would be easy enough to simply drill a side hole (s) through the . Tripp Lite’s N206-SB01-IND surface-mount junction box is ideal for connecting Cat5e/6, 4K HDMI or USB 3.0 installations in outdoor applications and other areas where protection from harsh elements is essential, such as factories and warehouses. It is constructed with a high-impact polycarbonate (UL94V-0) housing and flexible rubber gaskets.

0 · waterproof junction box installation

1 · polycase junction box

2 · poly case junction box nec

3 · junction box wiring diagram

4 · how to install junction boxes

5 · how to connect junction boxes

6 · electrical junction box installation

7 · diy electrical junction box

【Secure Locking Mechanism】: With a reliable lock, you can trust that your valuable electrical equipment will be safe and secure inside this metal box. 【Versatile Usage】: Whether you need to protect electrical junctions, wiring, or other sensitive components, this waterproof metal electrical enclosure is the perfect solution.

waterproof junction box installation

After opening the outlet up, it appears that the metal box has no grounding screw and the existing grounding wires are wrapped behind the mounting screws (the box has two mounting bracket, one on the top and one .

The only mounting holes currently in the junction box are in the bottom of the box- there are none on its sides. It would be easy enough to simply drill a side hole (s) through the . Overcrowding the junction box, using the wrong type or size of the box, poor wire connections, and neglecting proper grounding are pitfalls to avoid. Overcrowding can lead to overheating, while using an incorrect box may result . The bracket has tabs that must be perfectly horizontal in order for the fixture to be level. The junction box only has holes oriented perfectly up/down and right left, while the holes in the bracket only have holes slightly adjacent to .

adrian steel tool box

polycase junction box

There are a couple of them out there that specifically state that you are not to cut a hole in the top of the box no matter how you terminate the conduit. This may be because of .

Hey all, my 2 cents: a hole in the back of a pancake box seems bad and it is so easy to correct that why wouldn't you just do it? One way, remove the box, use a 1-inch or so . A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings. It looks too small to let in critters so probably won't cause any problem by leaving it in, but the answer below shows what you would use if you want to cover it. To use the knockout plug (as in the answer) first you remove . In a couple of rooms there are outlets with stripped screws so that they are not secured to the junction box anymore. Instead of opening up the wall and replacing the box, it’s way easier and faster to drill and tap the holes up to .

Remember Junction boxes have to be accessible. Under the insulation is not acceptable. Metal boxes are better when you need the strength and volume to make up a ton of wires. The blank covers fit better than a .

The junction box only has holes oriented perfectly up/down and right left, while the holes in the bracket only have holes slightly adjacent to those positions. Here are some pictures for reference: . Outdoor Recreation. .Junction box suggestions might be helpful - something like a NEMA 3R type steel junction box, or a 4x4x2, 6x6x4, etc PVC junction box. Either one can be drilled with holes sized and positioned to suit the job with a hole saw or step drill. That particular pancake box isn't intended to support the weight of the fixture. The light fixture crossbar mounts directly to the joist or stud using wood screws passing right through the holes in the box. And of course, if the stud isn't behind the holes there is nothing for the screws to grip. Rotate the box so the holes align with the stud.

Once you have a hole, stop. Drill it. Once you have a hole, get a decently sized bit (I find 1/4" works well here in both girth and length), put it into the hole you made, and carefully ream the hole out. The thinner knockouts will put up little resistance, but the main box won't let the bit ream it easily.There's a gap between the flimsy siding of my home and this electrical outlet. The cover won't drill closer to the vinyl to seal the gap despite having a weather guard.Which you have already mentioned is selling the house and the new owner having no idea this junction box exists. They won’t know of a potential hazard and while you may not be affected, there are definitely ethical considerations most people will be bothered by. Ease of access. Let’s say the lightening situation occurs.

advanced metal fabrication and finishing

You need to have a waterproof seal between the box and the extension ring. So either get an extender that fits inside the wall or replace the box with an outdoor box which extends past the wall a bit and allows a watertight seal between the box and the cover.(It is best to replace the inside box with an outdoor box.)

I removed a Romex cable that was going into a junction box top middle opening(you can see in the picture). . (depending on supplier - some are over a buck, I'd keep shopping), snaps into the hole (take the clamp out first.) Share. Improve this answer. Follow . How to feed electrical wire from switched outdoor sconce to junction box? Hot .

Now, let's discuss why drilling a hole in a junction box is necessary. When wires pass through a junction box, they need to be properly secured and protected to prevent any potential hazards. By drilling a hole in the junction box, you create a designated entry point for the wires to enter and exit the box. This ensures that the wires are .

well, i figured since the last 100 years there has been no problem why install junction boxes now? I'm repainting the hallway and in removing the old wall sconces i found that there were NO junction boxes installed and the lights worked just fine with no junction boxes. is there a way i can secure the new wall sconces to the plaster? and attachments in the industry?Why do junction boxes have to be easily accessible? Finding lots of resources explaining how junction boxes can't be buried in walls / ceilings, and must be easily accessible. But not finding much information as to why that is the case. . Obviously buying lids for the bins, but is there an easy way to fill the pipe holes. I'm thinking .My house has an outdoor motion sensor light and another regular light. I am having an electrician visit to install a proper junction box so I can install the Nest floodlight camera in both locations. Neither of these locations have a proper junction box like you see in the installation video.Why don't manufacturers drill holes into the pots Because then your floor or windowsill gets wet and dirty, or alternatively the decorative pot has to stand on a plate, usually taking away from the aesthetics. You're supposed to take a basic soft plastic pot - those that all do have holes in them - and put that inside a decorative pot.

Types of Junction Boxes. Circular: A circular junction box is shaped like a circle and is typically used to house electrical wires and connections. These boxes are often used in older homes and are designed to .Most of the time fiber is used since it's a pain to properly ground UTP cable. If you couldn't do fiber, I'd have converted to coax for an outdoor run since that's easy to ground. Also if you note that box does NOT have a grounding screw like the .

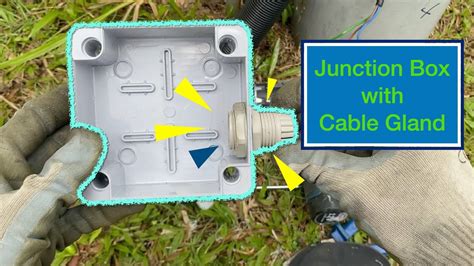

Use waterproof junction boxes made of polycarbonate, aluminum, or fiberglass to protect outdoor electronics from rain and moisture.. Look for boxes with a high IP rating (such as IP66 or IP68) that strongly seal against water.. Adding ventilation and drainage holes can also help prevent moisture buildup inside the box. Most have instructions that have no guidance except to say that the IP rating will be compromised if you drill a drain hole. However the instructions with a make (rated IP55) new to me say that a drain hole is required if cables are glanded from the top or side and also if the bottom entry gland completely seals!I have the same situation; my fixture actually came with its own special bracket that allows the canopy to be screwed in from the sides. We also wanted to put a ceiling rose over the ratty hole in the drywall, so between the height of the rose and the setback of the box, the bracket needed to come out by 1/2" so the canopy could fit over the screwholes.

Exterior light without junction box. I went to replace my old outdoor wall light fixture and found that there is no electrical box behind the light. . and I assume they did this for a good reason. I would like to avoid drilling a big hole into the brick for an outlet box. Can I just bolt a shallow box like this https://garvinindustries .If there's no threaded hole for a ground screw, a clip is the easy way to go, rather than drilling and tapping the box. However, without a ground wire, the box itself may not be grounded, so understand that clipping the ground wire to the box might not do anything. I can't quite tell how the wires are fed into the box.If it's romex, GOD NO PLEASE GOD NO NO As long as you put a proper watertight connector and raceway in, punch as many holes as you see fit. I've been in electrical for 16 years, modifying the panel is expected half the time. In damp or wet locations, boxes, conduit bodies, outlet box hoods, and fittings shall be placed or equipped so as to prevent moisture from entering or accumulating within the box, conduit body, or fitting. Boxes, conduit bodies, outlet box hoods, and fittings installed in wet locations shall be listed for use in wet locations.

Some boxes have different size punch-outs to accommodate different size conduits. You can use knockout boxes with NM cable by connecting the cable to the box so that it always stays in place. One of the most common mistakes that people make is trying to shove too many cables through the same hole. Some boxes have two holes, while others have three. This junction box cover is labeled "under side" on the side that is supposed to go inside the box. Why? What is different about this side? Here, for comparison, is the other side. EDIT: In light of the accepted answer, here are close ups of the respective edges. It's really very subtle, but perhaps there are random instances where there is more .

No good. What you should be able to do is: Remove the existing siding mounting block; Cut as needed in order to install a proper box. Metal is my preference, but plastic will do. The key is to get a box of the proper depth such that the existing cable can reach with its sheath to just inside the new box. Install a new siding mounting block

The problem is the drywall is so broken the box won't hold. I suggest moving the box 3" to the left or right in a new hole cut to the proper size for the box the hold. Then patch the beat up hole. you could also move it up if left or right is not good for you.

poly case junction box nec

Waterproof your outdoor splices with the DryConn small, aqua/orange wire connector. This quality one-step connector is filled with a dielectric silicone sealant that surrounds splices, making it water and corrosion resistant. This is an ideal choice for outdoor electrical connections exposed to condensation, water vapors or dust.

why does outoor junction box have no holes|waterproof junction box installation