sheet metal processing equipment Tennsmith is recognized worldwide as a premier leader in the manuafacture of sheet metal fabricating machinery. We offer a full range of American-made sheet metal tools including . One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing valuable insights for DIY enthusiasts.

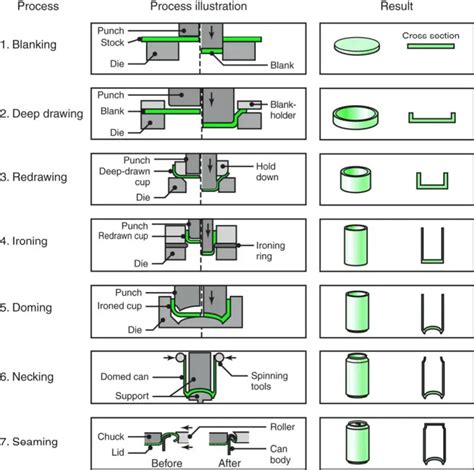

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal process in manufacturing

4 · sheet metal fabrication techniques

5 · sheet metal diagram fabrication

6 · disadvantages of sheet metal

7 · basic sheet metal fabrication techniques

With the appropriate 10 gauge wire, the right breaker, and a compatible receptacle, installing a 30 amp breaker and its circuit can be your DIY project. Follow this guide for more details. Step 1. Check for available circuit breaker slots in your panel. Step 2. Thread the electrical wire from the panel to the outlet. Step 3.

Tennsmith is recognized worldwide as a premier leader in the manuafacture of sheet metal fabricating machinery. We offer a full range of American-made sheet metal tools including .Contact - Tennsmith – Sheet Metal Forming and Fabrication Equipment You Know .Request a Quote - Tennsmith – Sheet Metal Forming and Fabrication Equipment You .

houston metal fabrication show

Up/Down Folders - Tennsmith – Sheet Metal Forming and Fabrication .Long Folders - Tennsmith – Sheet Metal Forming and Fabrication Equipment You .Metal Folders - Tennsmith – Sheet Metal Forming and Fabrication Equipment You .Roll Forming - Tennsmith – Sheet Metal Forming and Fabrication Equipment You .

Coil Processing - Tennsmith – Sheet Metal Forming and Fabrication Equipment You .

MetalForming, LLC. is the largest and oldest distributor of sheet metal processing machines in North America, providing equipment, software, training, and consulting services that enable .For flexible sheet metal processing, TRUMPF provides tailored machine tools and automation solutions, consulting, financing, and diverse services.CIDAN Machinery offers an extensive line of sheet metal machinery for virtually every aspect of sheet metal working. When it comes to bending, rolling, cutting, and forming metal – we’ve got .

Roper Whitney, the manufacturer's choice for sheet metal brakes, coil processing and forming equipment including bending, notching, punches and shears.Sheet metal machinery helps to cut, bend and fold sheet metal into specific shapes and sizes more easily, quickly, and efficiently. Sheet metal machinery can be classified into various industrial applications such as sheet metal cutting .As the largest supplier of high-end sheet metal folding and forming equipment in North America, Metalforming provides industry leading technology from global brands including Jorns, Schechtl, Schlebach, Krasser, Schroeder, Boeckelt . Certain sheet metal products require processing of aluminum profiles, with necessary steps such as avoiding blind holes and fish-eye pits. The conventional processing equipment employed in this field includes bench .

Schlebach GmbH is a leading manufacturer of rollforming, coil processing and curving machines and equipment for standing seam technology.

We have the widest variety of metal processing machines & equipment for leveling, deburring & coil line applications. From thin sheet metal to heavy plate!Through in-depth discussions with the clients, we gained insights into their demand for high-precision sheet metal processing equipment. After detailed product presentations and technical explanations, the clients made a final .Sheet metal processing, sheet metal processing manufacturers, stainless steel sheet metal processing, chassis sheet metal . molds and various specialized equipment. 7. Sheet metal connection The connection methods between .

The equipment used for steel coil processing varies depending on the specific processes being carried out. Below is a list of common equipment found in facilities that perform steel coil processing: . Beading Machine: A .

Coil Processing Equipment includes uncoiling, straightening, blanking, stacking and recoiling. We sell separate components as well as complete systems for HVAC, Architectural, Manufacturing and Service Centers. . Benoit Sheet Metal Equipment, Inc. has an extensive inventory of new and used sheet metal equipment in our warehouse in Kent . Contact us today to learn more about our sheet metal processing equipment. The Trusted Global Supplier of Stamping Equipment. (877) 447-7177 International Number: +86-(0)531-81616626 Home; About; Products. In Stock Presses; Metal Forming Machinery; Sheet Metal Processing Equipment; CNC Machine Tools;

Advanced, efficient, high-precision, complete perforated metal manufacturing and sheet metal processing equipment. Skip to content Email: [email protected] | Call: (0086)158-3286-8999COE Press Equipment manufactures Sheet Metal Coil Handling Machines & Equipment for integration into existing lines or building custom lines. . We offer a complete line of machines for processing metal coil stock for stamping lines including stand-alone coil reel, roll feeds, straighteners, shears, and stackers as well as complete integrated .Welcome to the definitive guide on sheet metal processing, an essential pillar in a multitude of global industries. From our daily commute vehicles to our indispensable household appliances, countless products we interact with everyday come to life through the intricate choreography of sheet metal manufacturing processes. Sheet metal processing is a method that manipulates .We, as the export department of our fabricator partners, are dedicated to help our customer improve the competitive power with our advanced technologies, advanced equipment, experienced people, high quality and cost-effective products, strong production capacity, and help our fabricator partners export the sheet metal processing service .

Laser cutting is a metal fabrication process that uses a thin, computer-controlled laser to cut through metal—such as stainless steel, aluminum, and more. The material melts, burns, vaporizes, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Laser cutting is an efficient sheet metal processing technique.COE PRESS EQUIPMENT 40549 Brentwood Sterling Heights, MI 48310 +1 (586) 979-4400Sheet metal working machines and equipment are a large group of metal working machines intended for versatile processing of sheet metal (bending, cutting, folding, etc.). Sheet metal machinery helps to cut, bend and fold sheet metal into specific shapes and sizes more easily, quickly, and efficiently.As a leading and professional manufacturer of industrial machinery, DERATECH offers a wide range of machines for sheet metal processing, including press brake, fiber laser cutting machine, hydraulic shear, grooving machine, turret punching machine, CNC punch-laser combination machine and more.

house with metal and coconut window boxes

The sheet metal processing equipment market is forecasted to grow by USD 4.38 billion during 2023-2028, accelerating at a CAGR of 6.33% during the forecast period. The report on the sheet metal processing equipment market provides a holistic analysis, market size and forecast, trends, growth drivers, and challenges, as well as vendor analysis .Capps Manufacturing, Inc. is an aircraft sheet metal fabrication & assembly facility in Wichita, KS.We’ve been a skilled provider of business and commercial aircraft sheet metal parts and assemblies since 1983.Our experienced team provides .If multiple holes are desired, the same equipment type can be used to make them. 2. Deformation . Sheet metal deforming processes involve changing and processing sheet metal without cutting it. Bending is one of the most critical .Sheet Metal Processing Services Sheet metal processing includes traditional cutting, punching, bending and forming methods and process parameters, including a variety of cold stamping die structure and process parameters, a variety of equipment working principles and control methods, but also including stamping new technologies and new processes. Tolerance as tight as .

The global sheet metal processing equipment market is poised for significant growth, with a projected increase of USD 4.38 billion from 2024 to 2028, according to a new report from Technavio. The market is expected to expand at a compound annual growth rate (CAGR) of over 6.33% during this period, driven primarily by the rising trend of . The process method of sheet metal processing through digital punching, laser cutting, shearing machine, bending machine, riveting machine and other equipment, generally used for sample production or small batch production, the cost is high. The processing cycle is short and the response is fast.

Get the sample copy of Sheet Metal Processing Equipment Market Report 2024 (Global Edition) which includes data such as Market Size, Share, Growth, CAGR, Forecast, Revenue, list of Sheet Metal Processing Equipment Companies (Amada Holdings, DMG Mori, Fanuc, TRUMPF, Komatsu, Haas Automation, Danobatgroup, Makino Milling Machine, Byjc .The sheet metal processing equipment market size is forecast to increase by USD 4.38 billion, at a CAGR of 6.33% between 2023 and 2028. The market is witnessing significant growth due to the rising industrial automation globally. This trend is driving the demand for advanced and efficient sheet metal processing solutions. companies in this .Sheet metal processing equipment are used to perform various operations on sheet metal like cutting, forming, and welding. Sheet metal is the metal that is turned into thin and flat pieces by an industrial process. The thickness of the sheet metal can vary with the application; for example . In semiconductor equipment sheet metal, the frame is the most important component. When designing and manufacturing the base/frame of the equipment, it should take into account what supports it and what is placed on top of it. . With over 30 years of sheet metal processing experience, BLIKSEN can accommodate stainless steel processing to .

Sheet Metal Forming Equipment. The relevant tools and equipment needed to form sheet metal will depend on what you want to make. For example, if you need specially shaped holes, cutting with punches and dies would be best. . There is very minimal post-processing needed with this method, and hardly any waste. It is commonly used in automotive .Workshop equipment. Workshop furniture Bench vices, . Home > products > Machinery > Sheet metal processing > bench chamfering machine. BENCH CHAMFERING MACHINE. Art. 0560. Where to buy. add to favorites. Chamfer. 45° 0 - 5 mm. Speed. 2800 rpm. Motor. 230 V 50 Hz 0,25 kW. Table dimensions. 2 - 400 x 50 mm.Bryan joins Haas Sheet Metal manager Joe Krivda for a tour of the facility where we do much of the sheet metal fabrication used on Haas machines. All the par.

Customers count on Formtek’s innovation and technology for superior coil metal processing equipment and technology. Formtek offers a variety of coil processing solutions to meet your specific challenges including edge conditioning systems, coil slitting, and levelers. . from coil or sheet handling through finished product, for your .

various sheet metal processes

how accurate is a cnc machine

types of sheet metal process

types of sheet metal fabrication

I’m using metal box has two ground screws, can I wrap around one ground wire (from supply side) on one of ground screws then connect it to the outlet and connect another ground wire (or two wires ) going to the next box(es) on the secondary ground screw?

sheet metal processing equipment|types of sheet metal fabrication