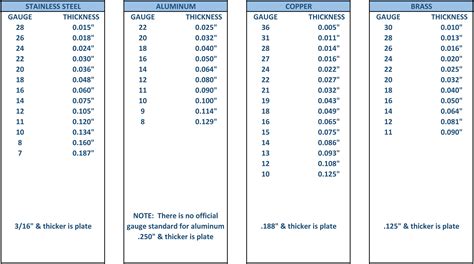

types of sheets in sheet metal Many different types of metal can be processed into sheet form, including aluminum, brass, copper, steel, titanium, tin and stainless steel, to name some common ones. Sheet sizes also come in multiple thicknesses. Sheet . Box springs do what the wooden base does, but adds additional compression that will make the mattress softer and/or springier, which can make a too-stiff mattress just right or a just-right .

0 · which thickness called sheet metal

1 · where to buy sheet metal near me

2 · types of sheet metal material

3 · sheet metal material list pdf

4 · sheet metal material list

5 · characteristics of sheet metal

6 · 4x8 sheet metal price list

7 · 20 gauge sheet metal lowe's

What are the common types of welding for sheet metals? There are five common welding approaches for sheet metal, including TIG, MIG, Stick, Laser beam & plasma welding. What is the thickness limit for sheet metal welding? O.8 mm is .

Types of Sheet Metal. Commonly used sheet metal materials can be divided into two categories, which are: Galvanized steel; Stainless steel; . Many different types of metal can be processed into sheet form, including aluminum, brass, copper, steel, titanium, tin and stainless steel, to name some common ones. Sheet sizes also come in multiple thicknesses. Sheet .Different sheet metals can be used in unique ways. In this article, we'll discuss Galvannealed sheet, HRPO sheet, and more along with their common uses.Today’s most common sheet metal types in industry include stainless steel, aluminum, carbon steel, and copper. Understanding your project’s specific needs is the key to choosing the suitable sheet metal. Consider factors like strength, .

Types of Sheet Metal. Aluminum: Aluminum sheet metal is known for its lightweight yet strong properties, making it a preferred choice in the aerospace and automotive industries. Its high corrosion resistance, along with .

Understand Your Project Requirements. The single most important consideration when purchasing steel sheets is your project specifications. Every project has unique needs that affect the type and grade of the steel you purchase. Step .

Carbon Steel. Carbon steels are one of the most versatile and widely used types of steel. It is made by adding an amount of carbon to iron, which results in a strong material that can withstand temperatures and . Here are some common types of sheet metal: 1. Mild Steel Sheet Metal. Mild steel sheet metal, also known as low-carbon steel, is a popular choice for many applications. It is .

Varied metals and metal alloys can be formed into sheets and used to fabricate sheet metal parts. The choice of materials depends on the requirements of the application and factors in material selection include: Formability. Weldability. . This is hard to explain, but sheet metal is originally manufactured using a process that rolls the sheet into a tight coil. These coils are generally transported in the United States, by trains and railcars. Most large sheet metal . Explore the various classifications of metal sheet materials, their properties, and industrial applications in this comprehensive guide for engineers and fabricators. . Currently, four main types of BH steel sheets have been .

Utilizing a comprehensive cold working process, manufacturers are able to form thin sheets of metal into a variety of components. This process, known as sheet metal fabrication, is highly versatile and includes steps, such .There are many combinations of Steel Plate and Sheet types and finishes. From types such as A36 or 516-70 to finishes from hot rolled to cold rolled. . A few of the most common grades of steel plates and sheets are: A36 - a low carbon steel with good strength, formability that can be securely welded with a minimum yield strength of 36 . Mild steel sheets are another alternative for steel sheets. This type of metal sheet is neither too ductile nor brittle. They are easy to manufacture, versatile, and affordable. This makes them applicable in the automobile and construction industries. Things to Consider When Buying A Sheet Metal. Knowing the type of sheet metal is not the only . Sheet metal joints are connections or seams formed by joining two or more sheets of metal to create a unified structure or component. From riveting and welding to folding and soldering, sheet metal joints offer an array of techniques and approaches that are critical in achieving the strength, stability, and functionality required in applications as diverse as .

2. Sheet Metalworking Defined Cutting and forming operations performed on relatively thin sheets of metal Thickness of sheet metal = 0.4 mm (1/64 in) to 6 mm (1/4 in) Thickness of plate stock > 6 mm Operations usually performed as cold working ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/eOur guides include: Product Guide – Provides an inspiring overview of the different color solutions that Steelscape offers.; Color Design Guide – A comprehensive overview of modern color trends and finish options for metal roofs and walls.; Metal Wall Design Guide – Designed to enlighten building designers as to the shape and color possibilities available with single skin metal wall .

Bending Machine Type Description Applications; Sheet Metal Bending Machine: Specifically designed for bending metal sheets of various thicknesses into intricate shapes. Common tasks include bending, curving, and folding metal plates at different angles. Automotive body panels, electronic enclosures, HVAC ducts: Pipe Bending Machine

There are many different sheet metal and alloys that come in metal sheet form and are ultimately used in the fabrication of manufactured parts. Which to choose.

With various metal alloys and manufacturing processes like galvanizing and electroplating determining the types of metal sheets, each can be differentiated accordingly. On that note, it’s time to get into the depth of the 9 types of sheet metals and their diverse uses. . Uses of Galvanized Sheets. Another popular type of metal sheet with . Sheet metal work. In sheet metal work, different types of metal sheets are used. The sheets are specified by their standard gauge numbers. It is very essential to know the different uses and applications of these metal sheets. Tools used in the sheet metal work are; Measuring tools. Steel rule; Outside micrometer; Vernier caliper; Combination set

raco steel electrical boxes fire rated

The most commonly used grade in sheet metal processing is austenitic stainless steel, particularly Type 304 (US designation) or 1.4301 (European designation). This grade is equivalent to the Japanese Industrial Standard (JIS) SUS304, which corresponds to the chemical composition of 18% chromium and 8% nickel (18-8 stainless steel). Several types of notches, dimensioning & tolerancing principles, the necessity of notches and tabs, disadvantages, and applications. Services. . Custom cut sheet metal shapes flat metal sheets into customized products. read more. Sheet Metal Design Guidelines: Optimizing for Manufacturability. Nov 8, 2024.

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. . In the realm of metal fabrication, sheet metal folding machines stand as indispensable tools, transforming flat metal sheets into intricate shapes with surgical precision. These versatile machines come in various types, each tailored to specific applications, empowering engineers and craftsmen alike to realize their creative visions. Roll-Forming .Galvanized sheet metal is metal which has been coated in a protective layer of zinc to prevent rusting and to protect the metal from the elements. Galvanization is typically performed on iron or steel, and steel is often galvanized while in . What Are Steel Sheets? Steel sheets are made by beating and flattening steel into thin parts. The thickness can vary depending on the type of steel and the rolling (flattening pressure). Standard steel sheets typically range from 30 to 7 gauge, but custom sheets can be outside of this range. Note that the higher the gauge, the thinner the sheet.

Sheet metals are used in different fabrication processes. This is to say that sheet metal is important in the field of metalworking. Awareness of the different types of sheet metal is very crucial as it guides one while choosing what to use for a given application. For this reason, this essay will try to cover everything one needs to know about various sheets of metals that . 5. Wiping. Wiping die bending or edge bending is a modification of the folding manufacturing technique. It is simply another plastic deformation of sheet material.. The working principle of the method is holding a workpiece between a pad and a die and sliding the wiping flange/punch down.Perforated metals are sheets of metal that have had decorative shapes and holes punched or stamped into their surface for both practical and aesthetic purposes. The perforation process can create a variety of geometrical patterns and designs, making it versatile for numerous applications. . The key factor in the process is the type of sheet .

As such, this article explores the world of galvanized sheet metal, covering its definition, differences from non-galvanized alternatives, and the various galvanization types. In addition, it will provide a guide on how to galvanize sheet metal and detail the advantages and diverse applications of this versatile material.

which thickness called sheet metal

Varied metals and metal alloys can be formed into sheets and used to fabricate sheet metal parts. The choice of materials depends on the requirements of the application and factors in material selection include: . Standard type magnetic stainless for sheet metal fabrication is the 400 series. Grade 410 offers less corrosion resistance but is .Today's most common sheet metal types in industry include stainless steel, aluminum, carbon steel, and copper. . Sheets are flat, coils are rolled, and strips are long and narrow. The Manufacturing Process: How sheet metal is produced and processed. Sheet metal starts as molten metal. The liquid metal is poured into molds or directly onto a . Discover the 7 most common sheet metal joint techniques that include riveted, welded, and adhesive joint types for appropriate enhancement of structural rigidity and effectiveness in your projects. . About. Profile; Milestone; Vision & Mission; Core Values; Products. Architectural Architectural metal sheets and panels constitute key materials .

raco electrical box catalog

What makes stainless steel sheets essential in various industries? From kitchen appliances to civil engineering, these versatile materials offer corrosion resistance, strength, and durability. This article explores the types of stainless steel sheets, including their unique properties and applications. Readers will gain insight into how these materials enhance product longevity .

Types of Sheet Metal. Aluminum: Aluminum sheet metal is known for its lightweight yet strong properties, making it a preferred choice in the aerospace and automotive industries. . You should store sheets horizontally on racks to avoid bending or warping and secure them to prevent sliding or toppling. When moving sheet metal, it’s .

raco electrical boxes 2 gang metal

r r sheet metal fabrications

raceway and boxes for electrical systems

Here are the essential items needed for a seamless copper welding experience: a. Tig Welder: Invest in a high-quality Tig welder that offers precise control over the welding parameters such as heat input, amperage, and pulse settings. Look for a welder with adjustable settings specifically designed for welding copper. b.Get the look of traditional metal roofing with Clicklock Premium Standing Seam. The Visualizer Tool will help you find the right style of metal roofing shingles for your home. What Color of Metal Roof?

types of sheets in sheet metal|20 gauge sheet metal lowe's