how to form a cone with sheet metal The first step in fabricating a cone from sheet metal is determining the dimensions of the cone you want to create. This includes the base diameter, top diameter (if it's a frustum), and the height . We provide advanced machining and secondary services, including CNC, Swiss, multi-spindle, Davenport, Acme, and Hydromat, to manufacture carbon steel turned parts, components, and fittings.

0 · truncated cone from flat sheet

1 · sheet metal transition layout

2 · sheet metal cone rolling calculation

3 · sheet metal cone formula

4 · sheet metal cone fabrication

5 · creating a cone layout

6 · cone sheet metal calculator

7 · cone layout formula

Shandong Novatech Heavy Duty Machine Tool Co.,Ltd: Welcome to buy large horizontal CNC lathe, cathode roller CNC lathe, CNC horizontal roller lathe in stock here from professional manufacturers and suppliers in China.

Here is one way to make a cone from flat stock. I used aluminum sheet coil but you could use paper or any flat material. You can find cone calculators online, I used this particular cone .

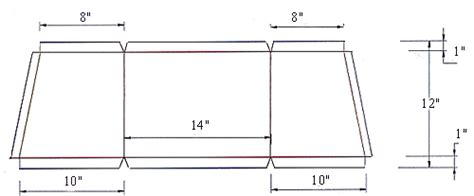

Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It . Forming the cone can be done using a variety of techniques, including rolling and welding, or by using a cone-rolling machine. Professional sheet metal fabrication companies have the expertise and specialized . Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.

The first step in fabricating a cone from sheet metal is determining the dimensions of the cone you want to create. This includes the base diameter, top diameter (if it's a frustum), and the height . Layout of a cone template for sheet metal fabrication. Stephen Marchio. 7.25K subscribers. 758. 99K views 4 years ago. .more. Whether you need to replace a damaged cone or create a custom design for your project, learning how to make a sheet metal cone can save you time and money. In this step .Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with .

This video shows how to make cones from 1/8-inch (3.2mm) steel, using simple shop-made equipment.In this guide, we've covered the essential steps for fabricating a sheet metal cone. With the right tools, materials, and a bit of practice, you can create custom sheet metal cones tailored to . Here a video how to make an Eccentric Reducer

Learn how to roll sheet metal into a cone with a DIY Snubber Attachment.Make your own simple Snubber to make rolling a steel cone easy.00:00 Intro What's a S. Pt1. Introduction - https://youtu.be/VPwwbUz7p34Pt2. Square Based Pyramid Development - https://youtu.be/3h9uDY67NQ8Pt3. Frustrum of a Cone Development - htt. Metal domes are often spun (watch Youtube for Spun Metal) but you don't really have much of a dome there, it's more of a heavily filleted cone. The method Reis describes what armorers use and that is what you need here since it's actual (fantasy) armor. With these methods you can get the whole shape from one sheet if you are skilled. I've used a slip roll to form flats and sheets into circular shapes before, but I'm wondering what it takes to make a cone. I don't have a slip roll currently, nor do i have access to one at the moment, so i can't do any testing, but can you form a cone with one or does it require a special type of roll? to make a cone, one edge of the sheet must pass through at a far greater .

Step 8: Benefits of Fabricating a Cone From Sheet Metal. There are several benefits to fabricating a cone from sheet metal, including: Sheet metal is durable and can withstand harsh environments. Sheet metal cones can be made to exact dimensions, ensuring a perfect fit for any application. Sheet metal cones are lightweight and easy to transport.

Lie your cone in the middle of a piece of construction paper, with the top of the cone at the top of the paper. Make a mark on the paper at the bottom of the cone. Remove the cone from the paper and cut the bottom of the construction paper off at the mark that represents the bottom of the cone. This cut is a straight line.1 piece cone model the cone as a solidbody revolved 359.9deg. Convert to sheet metal by selecting an edge. Leaving the gap allows it to be converted to sheetmetal. 2 piece cone can be revolved 180 deg as a solidbody. Lofting cones does not . SolidWorks Tutorial Sheet Metal Cone Tutorial video how to make cone in solidworks

truncated cone from flat sheet

There are many reasons that you might need to bend a cone from sheet metal. Metal cones are good for finishing chimneys, topping off certain types of outdoor fire and grill buildings and occasionally for decor purposes. Home Sweet Home Hacks, Tips & Tricks Squeaky Clean .In this video, I show how to make a reducer from sheet metal

Also, the tip of the cone is never going to form precisely right, so you really need to look at truncated cone to form it. If you are forming it by hand, good luck. That tip is going to be horrendously hard to do with out creasing your metal. The thinned you make it, the easier it will be to roll, but the more likely to crease at the tip.

JD goes over this BEAST of a Slip Roll and Why you want one in your garage! MORE INFO: https://www.eastwood.com/eastwood-heavy-duty-50-inch-slip-roller-with-.Video showing the processes involved in producing a steel cone. It a job that requires a little skill and a lot of patience! Video title: How to Roll a Cone – Midland FabricationIn this video students James & Luke talk us through how to roll a cone in a set of pinch plate rolls. Th.

A Paper About Sheet Metal Cone Rolling. The cylinder and the cone can be regarded as the cylinder and the cone of the workpiece are rotated 360 degrees around the rotation centerline in the same plane. The bar of the cylindrical workpiece is parallel to the rotation center line, and the busbar and the rotation center of the cone workpiece. Tilt .Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with . How to use the Sheet Metal Features in Autodesk Fusion 360 (for Complete Beginners) Learn how to create sheet metal cone.TEACHING THE NEXT GENERATIONTUTORIAL.

Beginning with a plain piece of 22 gauge stainless steel sheet metal, I demonstrate how to roll a cone. One side of the roller is compressed more than the o. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .Sheet metal cones are versatile and essential components in various industries, including construction, HVAC, automotive, and aerospace. They serve a wide range of functions, from decorative elements to structural supports and ductwork. . Step 5: Form the Cone . Align the straight edges of the cone's development, forming the cone shape. You . Then with a template of a circle with the desired circumference drawn on cardboard just push the sheet metal circle into a cone using template to get the circumference. Then mark and trim the excess as needed. I usually leave a little overlap and use self tapping to secure. This is how I make cones for bottom of barrel feeders by cutting a .

The ratio of the largest to smallest cone diameter and the cone angle (α) influence the limiting draw ratio (LDR) for most conical draws (Fig. 2). When α measures < 20 deg., the cone can usually be processed in the same manner as a cup draw. Shallow cones, with a ratio of h/d2 < 0.30 and a measures > 45 deg., usually can be drawn in a single .

sheet metal transition layout

cnc manchining welding parts

How do you make a cone shape? How do you make a funnel with sheet metal?How do you make a flat material cone?How do you cut a cone shape out of sheet metal?h.

After the metal has aged and dried. Cut off a large corner from the sheet metal material. Begin to manipulate the two corner edges rolling in toward each other. Tightly roll the corner into a cone shape. Roll the metal tighter than you want the shape to appear. Mark a straight line along the bottom edge of the cone shape to the height you want.Learn how to form a cone by cone bending on Revolution Machine Tools R-SMART 6-709 4 Roll Plate Roll.Presented by Atakan NerminerTo learn more visit http://w. Reverse engineering the cones in Fusion 360

cnc manufacturing products

sheet metal cone rolling calculation

OEM ODM CNC machining service since 1999. aluminum,brass,stainless steel cnc machining parts manufacturer Brass Fasteners: CNC machining is used to create custom screws, bolts, nuts, and other fasteners for specific applications. Brass Fittings: Custom brass fittings, such as couplings, adapters, and connectors, for plumbing and hydraulic systems.

how to form a cone with sheet metal|sheet metal cone rolling calculation