sketch driven sheet metal part Online sheet metal fabrication service. Get custom parts delivered in just a few days—upload STEP or DXF files for instant pricing! As a union Sheet Metal Worker, you will belong to a skilled technical craft. Sheet Metal Workers work in a shop and in the field. They use mathematics and pattern development methods to fabricate.

0 · transformed sheet metal sketches

1 · solidworks transformed sheet metal

2 · solidworks sheet metal sketches

3 · solidworks sheet metal shape

4 · solidworks sheet metal parts

5 · solidworks sheet metal diagram

6 · sheet metal sketches

7 · shaped sheet metal sketches

Portable Metal Tool Box, 3 Drawer Steel Tool Box with Top Storage Tray and carrying Handle, Multi-Function Tool Storage with Anti-slip Liner for Garage, Home, or Workbench (Black)

However, you can leverage 3D modeling commands (surface modeling, Boundary Patch, Shell, and Thicken) to create the main shape (non-sheet metal part). Then use sheet . Design a sheet metal enclosure for a previously-built part, and place the part into the enclosure using SOLIDWORKS. You'll learn about design, in-context relations, interference detection and more.Online sheet metal fabrication service. Get custom parts delivered in just a few days—upload STEP or DXF files for instant pricing!

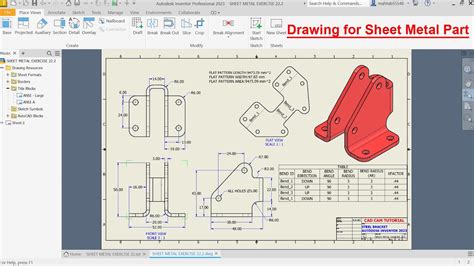

Sheet metal parts can have sketches in the Folded and the Flat Pattern states (Fig. 1) Sketches created in the folded state can have an equivalent “transformed” sketch in the Flat Pattern state. All sheet metal parts have a .Take your sheet metal skills to the next level by designing a sheet metal enclosure with SOLIDWORKS in this project-based course.Learn to design a sheet metal electrical enclosure using SOLIDWORKS, covering base flanges, edge flanges, miter flanges, hole wizard, and vent features for assembly line processing equipment. In SOLIDWORKS, a Sheet Metal Sketched Bend is a method of adding a bend to a sheet metal part relative to a line in a special sketch. This special sketch is created within the Sketched Bend command. Sheet Metal .

Example of a fan scroll sheet metal part that uses a layout sketch, parameter file and design function / equation table.In Onshape, you can initiate a sheet metal design using several methods: you can convert a solid part into sheet metal; design from a flat sketch, then fold; use flange tools to add edges and features; or directly import and adapt existing .To use a rip sketch when converting to sheet metal: Open the part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal . In the .Online sheet metal fabrication service. Get custom parts delivered in just a few days—upload STEP or DXF files for instant pricing! . Customize a part template using our Parts Builder, or send a sketch to our Design Services team. Get .

This sketch is used to make a sheet metal face that will be the base feature for the scroll. This sketch is made symmetrical about Y - axis and all dimensions linked to equations from the "ROTOR_DIA" variable. Step 4: . Another workflow to consider is to create an actual tab tool (positive) as an ipt file. Then simply derive it as a body into a sheet metal part. Then you can populate the tool by using Sketch-Driven Pattern (join as one .

SOLIDWORKS Sheet Metal - Sketch-driven Enclosure Assembly Design: Learn how to design sketch-driven enclosure assemblies in SOLIDWORKS Sheet Metal with our comprehensive online course. . Creating Another Part, Modifying the 3D Sketch Design Envelope Part 30m 56s Exploring the Tab, Jog, and Hem Sheet Metal Tools, Working in an In-context .Starting with Creo Parametric 5.0, when you convert a solid part to a sheet metal part you can include and exclude surfaces to obtain a constant wall thickness, recreate rounds and chamfers, and use additional options. 1. Click Driving Surface. 2. The References tab opens by default. a.Do an open sketch (like you would a thin extrude) of the profile of the sheet metal and do a base flange/tab? Not sure if that's helpful at all haha, but you can define the sketch with the requirements you're asking for, which would then define the sheet metal that way.

Currently, I do a 3d sketch with 3d sketch planes to draw up the shape. From there, I've been tracing each individual face in a separate sketch, then creating planar surfaces off of each one. Other than being time consuming, when I try to convert to sheet metal, it .If the center points have imported with this, you may be able to use those as a sketch driven pattern. You can filter your selection to select the center points, invert the selection and delete the arcs. If you need dimensions, you can just use the Fully Define Sketch tool on the sketch. . Hi everyone, been working on this flat sheet metal . Exit sketch. 3. Place a Workpoint on one of the sketch center points. Create a Sketch Driven Pattern, select the Workpoint. Turn off visibility of the workpoints. 4. In the assembly SWITCH TO MODELING VIEW in the browser (only way to select the pattern of Workpoints). Component pattern, select the Sketch Driven Pattern in the browser. 5. Bam.

SOLIDWORKS Sheet Metal - Enclosure Part Design. SOLIDWORKS Sheet Metal - Sketch-driven Enclosure Assembly Design. SOLIDWORKS Essentials - Sheet Metal 101. Solidworks Sheet Metal. Discovering the Use of Weldments & Sheet Metal Design: SolidWorks. SolidWorks Tutorial for Beginners. 3.3.

Sheet metal parts can have sketches in the Folded and the Flat Pattern states (Fig. 1) Sketches created in the folded state can have an equivalent “transformed” sketch in the Flat Pattern state. All sheet metal parts have a fixed face. The fixed face is the one that remains in the same position when unsuppressing the Flat Pattern. (Fig. 2)Sheet Metal: Simulation: SimulationXpress: Sketching: Sustainability Products: SolidWorks Utilities: Tolerancing: Toolbox: Weldments: Workgroup PDM: Troubleshooting: Glossary: Example of Multibody Part with Sketch Driven Patterns. Multibody part with Body to Pattern and sketch points. Sketch driven pattern applied.

The fold tool in sheet metal seems to want a new sketch for each fold line. Is there a way to fold this part using the existing construction lines in the sketch? Thank you. Autodesk Inventor Professional 2024 64-Bit Edition Build 343, 2024.3 Update - Date: Mon 3/18/2024 ; Autodesk Vault Professional 2024 Build 29.3.71.0 2024.3 Update

Sheet metal design is really difficult, but it still needs continuous exploration and discovery It is uncertain which day a capable man will solve the problem Sheet metal design is mainly about unfolding, blanking, unfolding .It is a rolled sheet metal part. I tried using your FS in the flat view, but that does not work. You are not able to select sketches or features in the flat view. I could do it in the rolled 3D view, but the feature needs to be kept tangent to the . Hi! Here is another approach. Basically, I create a double-circular pattern of workpoints. Place the part and a cylinder tool in an assembly. Use feature-based component pattern to pattern the cylinder tool. Lastly, derive the assembly (set the cylinder to cut) as the final part. Please let me know if you have any question. Thanks!

house made of metal cladding

As far as I know the only way to make a sheet metal part bent along a spline is with lofted bend. You would sketch the profile you want, use convert entities to copy it to a parallel plane, then you can use those two sketches as your profiles for a lofted bend using the formed manufacturing method. Then you can just use an extruded cut to match . Sketch driven patterns was a game changer when it came out a few years ago. I wanted to share a little video on how you can push that functionality to assemblies as well. The main benefit being you can pattern components with varying spacing. Also being able to specify direction is very nice too. I've used it in assemblies for all kinds of things like placing brackets, .A feature created from a sketch. Bend Allowance Options. Use a bend table, k-factor, bend allowance, bend deduction, or bend calculation. . Flat Pattern feature. Bend Tables. Specifies the bend allowance or bend deduction values for a sheet metal part in a bend table. Corner-Trim tool. Cuts or adds material to flattened sheet metal parts on .

Sheet metal information: Transfers the sheet metal and flat pattern information from the original part to the mirrored part, such as fixed face, grain direction, bend lines, and bounding box. Unlocked properties: This option allows you to edit the sheet metal definition in the mirrored part, which will update the cut list properties. I did a cut on the pipe. Then derived it into a sheet metal part, made the sheet metal .010 thick, thiner is better, cuts down on errors. Derive the planes and sketchs you used on the pipe and cut the sheet metal part. Look thru both parts and see if it helps youClick in Components to Pattern, then select the seed components.; To restore instances, select the instance in Instances to Skip and press Delete.; Optional: To block changes to the configuration of patterned instances for all configurations, select Synchronize configuration of patterned components to seed. Click . Next, we’ll create a cut-extrude with that sketch. And then we’ll create a sketch-driven pattern that references the cut-extrude AND its sketch! So basically, one sketch to rule them all (that’s yet another book/movie reference)! With the sketch-driven pattern, every sketch point will result in another patterned instance of the feature.

Throughout these lessons, we will be creating a sheet metal part for an electrical enclosure confined and driven by a design envelope along with various tools including the edge and miter flanges, bolt holes, a vent, and various other features. Software required: SOLIDWORKS 2012 and up. Design a sheet metal enclosure for a previously-built part, and place the part into the enclosure using SOLIDWORKS. You’ll learn about design, in-context relations, interference detection and more. . Sketch Driven Sheet Metal Assembly Design is the perfect course for you. The course will cover the creation of a portion of an electrical .

transformed sheet metal sketches

solidworks transformed sheet metal

For example, we needed to glue a piece of wood to metal that was going to hold over 100 pounds. We needed to find out the absolute best type of glue or adhesive to use to hold these 2 different materials together.

sketch driven sheet metal part|sheet metal sketches