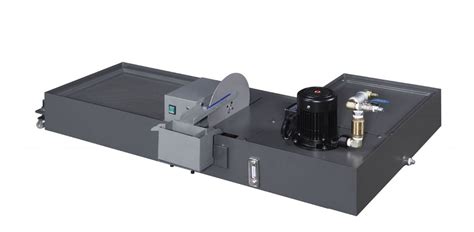

cnc coolant cleaning machine C.R.O.S.S. filters coolants and separates oils for CNC machining tools with individual coolant reservoirs. Designed for high-performance environments, the system ensures thorough particulate and tramp oil removal through a three-step process .

What makes LunchEAZE different? How does this smart electric lunch box work? What is our return policy? Check out our FAQs here.

0 · coolant tank for cnc machine

1 · coolant pumps for cnc machines

2 · coolant mixers for cnc equipment

3 · coolant gun for cnc machine

4 · coolant filters for cnc machines

5 · coolant cleaning for cnc machines

6 · cnc machine coolant health problems

7 · best coolant for cnc machine

You're going to need to either pull new cable from the nearest outlet/junction box on that circuit, which will not be easy since this is obviously NM cable, presumably stapled (as it should be) to studs along the way, or you're going to .

In this comprehensive guide, we will dive deep into the world of CNC machine coolant cleaners, exploring their benefits, types, how to choose the right one, best practices for cleaning coolant, .Explore our comprehensive guide on CNC coolant maintenance to boost your machine's performance and longevity. Learn about the latest strategies, tips, and best practices for effective coolant care and optimisation.In this comprehensive guide, we will dive deep into the world of CNC machine coolant cleaners, exploring their benefits, types, how to choose the right one, best practices for cleaning coolant, and more.

Explore our comprehensive guide on CNC coolant maintenance to boost your machine's performance and longevity. Learn about the latest strategies, tips, and best practices for effective coolant care and optimisation.

These powerful vacuum systems are engineered to maintain the cleanliness and integrity of coolant and cutting fluids, crucial for the optimal performance of CNC machines, lathes, mills, and grinders. The operation of a sump sucker is straightforward yet highly effective.C.R.O.S.S. filters coolants and separates oils for CNC machining tools with individual coolant reservoirs. Designed for high-performance environments, the system ensures thorough particulate and tramp oil removal through a three-step process .

The COOLCUT™ System Cleaner is the ideal product to add to your CNC machine tank before completing fluid changeovers and flushes. Biocidal agents help kill bacteria and fungus that might be growing in the machine or fluid reservoirs.

By following this guide, you will gain the knowledge and skills to properly clean and maintain your CNC machine coolant tank, ensuring optimal performance, extended machine lifespan, and significant cost savings in the long run.Cleaning the Inside Of The CNC Machine Use your degreaser and clean all surfaces, including the coolant nozzles if you’re not replacing them. If you’re replacing the coolant nozzles, pop them off and spray a little bit of WD-40 chrome and metal, and wipe with Scotch Brite pad. Midaco's automated CNC chip cleaning fan frees your operator or robot from time spent on chip cleaning tasks and reduces idle time in the machining process. Keep the chips and coolant INSIDE the machine tool.

Still cleaning the coolant tank in the traditional way? The chip / sludge removal machines solves your problems quickly and easily. There is no need to shut down for quick processing and you can easily solve the problems of dusty sludge deposition.Eliminating contaminants in oil based machine coolant has been proven to cut down wear in pumps, bearings, cylinders, motors, gears, servo valves and any metal surfaces used in or affected by the machining operation. A clean system will always run at higher pressures and maintain higher levels of accuracy and repeatability.In this comprehensive guide, we will dive deep into the world of CNC machine coolant cleaners, exploring their benefits, types, how to choose the right one, best practices for cleaning coolant, and more.

Explore our comprehensive guide on CNC coolant maintenance to boost your machine's performance and longevity. Learn about the latest strategies, tips, and best practices for effective coolant care and optimisation.These powerful vacuum systems are engineered to maintain the cleanliness and integrity of coolant and cutting fluids, crucial for the optimal performance of CNC machines, lathes, mills, and grinders. The operation of a sump sucker is straightforward yet highly effective.C.R.O.S.S. filters coolants and separates oils for CNC machining tools with individual coolant reservoirs. Designed for high-performance environments, the system ensures thorough particulate and tramp oil removal through a three-step process .

The COOLCUT™ System Cleaner is the ideal product to add to your CNC machine tank before completing fluid changeovers and flushes. Biocidal agents help kill bacteria and fungus that might be growing in the machine or fluid reservoirs.By following this guide, you will gain the knowledge and skills to properly clean and maintain your CNC machine coolant tank, ensuring optimal performance, extended machine lifespan, and significant cost savings in the long run.

Cleaning the Inside Of The CNC Machine Use your degreaser and clean all surfaces, including the coolant nozzles if you’re not replacing them. If you’re replacing the coolant nozzles, pop them off and spray a little bit of WD-40 chrome and metal, and wipe with Scotch Brite pad. Midaco's automated CNC chip cleaning fan frees your operator or robot from time spent on chip cleaning tasks and reduces idle time in the machining process. Keep the chips and coolant INSIDE the machine tool.Still cleaning the coolant tank in the traditional way? The chip / sludge removal machines solves your problems quickly and easily. There is no need to shut down for quick processing and you can easily solve the problems of dusty sludge deposition.

coolant tank for cnc machine

coolant pumps for cnc machines

coolant mixers for cnc equipment

$19.99

cnc coolant cleaning machine|coolant filters for cnc machines