butt welding sheet metal stud welder Butt welding sheet metal is a fundamental welding technique that involves joining two metal sheets end-to-end. This process creates a strong and durable weld, making it an essential skill for fabricators and welders across . Size: 1.25"w x 13"h x 9.75"d. Waddell’s versatile wood shelf brackets add just the right look for any shelving or countertop design you have in mind. Additional customization is available because you can install our wood brackets horizontally or vertically. Made of pine, our shelf brackets are sanded smooth, ready for your custom finish.

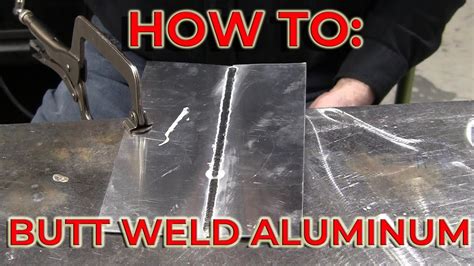

0 · how to butt weld sheet metal

1 · butt welding structure

2 · butt welding steel

3 · butt welding design

4 · butt weld material

5 · butt weld example

6 · butt joint preparation

7 · butt joint in welding

So far, the one product I've found that works on already rusted sheet metal is a Rustoleum product called (geez, can't remember, but will update when I get home and look at the bottle again). Using a small brush, I painted it on any rusty metal that I see and it turns into a shiny hard black thing. Almost looks like lacquer.

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt.

Butt welding sheet metal is a fundamental welding technique that involves joining two metal sheets end-to-end. This process creates a strong and durable weld, making it an essential skill for fabricators and welders across . A butt weld is a welding technique where two metal pieces are joined together along their edges in a single plane. This creates a strong and seamless bond, commonly used in the construction, manufacturing, and . Butt welds are a popular welding technique used in metal fabrication. They join two pieces of metal by heating and pressing the edges together, creating a strong bond. Different types of butt welds include gas .

Butt welds can be used when welding both thin sheet metal and thick metal, but there are specific steps in weld preparation. The thickness of the metal pieces will indicate whether the butt joints are square or beveled.Butt welding sheet metal is a very important skill to develop for replacing sheet metal in your restoration. Joint preparation and welder setup are the keys to a successful job. In the above .Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt. Butt welding sheet metal is a fundamental welding technique that involves joining two metal sheets end-to-end. This process creates a strong and durable weld, making it an essential skill for fabricators and welders across various industries.

The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW; Gas Tungsten Arc Welding (GTAW or TIG) A butt weld is a welding technique where two metal pieces are joined together along their edges in a single plane. This creates a strong and seamless bond, commonly used in the construction, manufacturing, and automotive industries for its reliability and structural strength. Butt welds are a popular welding technique used in metal fabrication. They join two pieces of metal by heating and pressing the edges together, creating a strong bond. Different types of butt welds include gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW).

Butt welds can be used when welding both thin sheet metal and thick metal, but there are specific steps in weld preparation. The thickness of the metal pieces will indicate whether the butt joints are square or beveled.Butt welding sheet metal is a very important skill to develop for replacing sheet metal in your restoration. Joint preparation and welder setup are the keys to a successful job. In the above video tips are given for the actual welding process as well as some setup information.Butt welding is a fusion welding technique used to join two pieces of metal along a single plane. It involves bringing the edges of the two workpieces together and then melting and fusing them to create a strong and continuous joint. Discover the art of butt welding with our detailed guide. Learn various methods, techniques, and tips to perfect your welding skills. Ideal for beginners and pros alike.

A butt weld consists of two pieces of metal placed next to each other “end-to-end” in the same plane. Applying a continuous weld down the centerline welds the pieces together. There is no stock overlap, and the joint can have a root opening.

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt. Butt welding sheet metal is a fundamental welding technique that involves joining two metal sheets end-to-end. This process creates a strong and durable weld, making it an essential skill for fabricators and welders across various industries. The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW; Gas Tungsten Arc Welding (GTAW or TIG)

how to butt weld sheet metal

A butt weld is a welding technique where two metal pieces are joined together along their edges in a single plane. This creates a strong and seamless bond, commonly used in the construction, manufacturing, and automotive industries for its reliability and structural strength. Butt welds are a popular welding technique used in metal fabrication. They join two pieces of metal by heating and pressing the edges together, creating a strong bond. Different types of butt welds include gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW).

Butt welds can be used when welding both thin sheet metal and thick metal, but there are specific steps in weld preparation. The thickness of the metal pieces will indicate whether the butt joints are square or beveled.

Butt welding sheet metal is a very important skill to develop for replacing sheet metal in your restoration. Joint preparation and welder setup are the keys to a successful job. In the above video tips are given for the actual welding process as well as some setup information.Butt welding is a fusion welding technique used to join two pieces of metal along a single plane. It involves bringing the edges of the two workpieces together and then melting and fusing them to create a strong and continuous joint. Discover the art of butt welding with our detailed guide. Learn various methods, techniques, and tips to perfect your welding skills. Ideal for beginners and pros alike.

butt welding structure

convert 24 gauge sheet metal to mm

control box schematics franklin electric 2823008110

butt welding steel

For sale is a great collectible for any Voltron fan. This is a lunchbox and thermos from 1984. Displays ok but has obvious flaws to it. Far from perfect! Thermos is included though. Please check out a.from

butt welding sheet metal stud welder|butt welding structure