basics of cnc machine pdf The first sections of the manual take you through the very basics of what a CNC Mill is and what operations it can do, the basics of how the machine works, what G - Code is, the different . Getting rid of unwanted plants and trees can be as simple as digging into your household cleaners. Borax, WD-40 and bleach all prevent plants from growing and will kill them. Once the chemicals have killed the unwanted plants, dig them up and dispose of them to prevent them from rooting again.

0 · types of cnc machines PDF

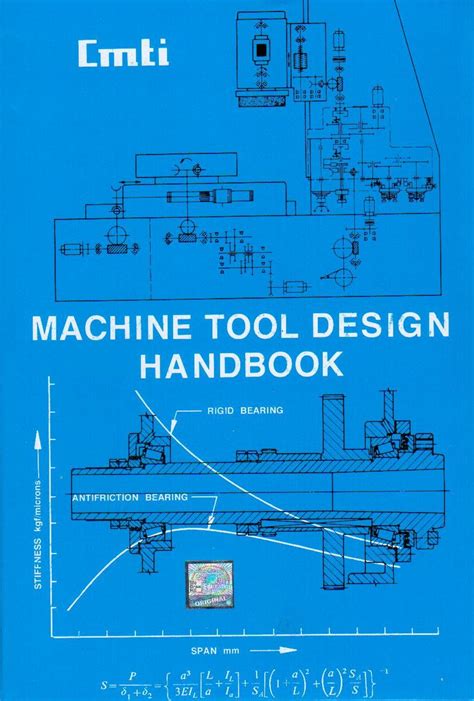

1 · cnc machine tool design PDF

2 · cnc machine manual PDF

3 · cnc machine drawing PDF

4 · cnc machine codes list PDF

5 · cnc machine books free download PDF

6 · cnc machine basic knowledge PDF

7 · cnc machine PDF download

Mig welding sheet metal requires precision and control to prevent warping or burn-through. A thin wire and low heat settings are essential. . Proper technique is crucial to avoid common issues like warping or burn-through. Using the right settings and tools, such as a thin wire and appropriate heat levels, ensures strong, clean welds .

The first sections of the manual take you through the very basics of what a CNC Mill is and what operations it can do, the basics of how the machine works, what G - Code is, the different .CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motorsTypes of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC .To maximize learning, this course focuses on CNC machines made by Haas Automation, Inc. of Oxnard, CA. Chapters 5 (CNC Programming Language) and 6 (CNC Operation) are written .

CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically .

Featuring hundreds of color images and schematic diagrams, CNC Handbook explains machining fundamentals and shows you how to build and safely operate fully automated, technically sophisticated mechatronic equipment.This guide to all things related to CNC machining will walk through how modern CNC machining processes work, including material options, design considerations, cost drivers, and more. .

11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC .iv 2. Implementation of Switching Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61 2.1 Tool .

types of cnc machines PDF

• Knowledge of the proper use of basic hand tools and precision measuring instruments, including calipers and micrometers. • Some manual machining experience is helpful but not required.The first sections of the manual take you through the very basics of what a CNC Mill is and what operations it can do, the basics of how the machine works, what G - Code is, the different types of tools that can be used and other practical things you need to know. This is followed by an overview of the actual TORMACH CNC Mill.CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors

Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC and HMC) • ATC types: carousel-type and swing-arm-type

To maximize learning, this course focuses on CNC machines made by Haas Automation, Inc. of Oxnard, CA. Chapters 5 (CNC Programming Language) and 6 (CNC Operation) are written specifically.

CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. • The development of NC machine tools started from a task supported Featuring hundreds of color images and schematic diagrams, CNC Handbook explains machining fundamentals and shows you how to build and safely operate fully automated, technically sophisticated mechatronic equipment.This guide to all things related to CNC machining will walk through how modern CNC machining processes work, including material options, design considerations, cost drivers, and more. Today, there are several technical processes included underneath the CNC machining umbrella.11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame)

iv 2. Implementation of Switching Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61 2.1 Tool .• Knowledge of the proper use of basic hand tools and precision measuring instruments, including calipers and micrometers. • Some manual machining experience is helpful but not required.The first sections of the manual take you through the very basics of what a CNC Mill is and what operations it can do, the basics of how the machine works, what G - Code is, the different types of tools that can be used and other practical things you need to know. This is followed by an overview of the actual TORMACH CNC Mill.CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors

Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC and HMC) • ATC types: carousel-type and swing-arm-typeTo maximize learning, this course focuses on CNC machines made by Haas Automation, Inc. of Oxnard, CA. Chapters 5 (CNC Programming Language) and 6 (CNC Operation) are written specifically.CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. • The development of NC machine tools started from a task supported Featuring hundreds of color images and schematic diagrams, CNC Handbook explains machining fundamentals and shows you how to build and safely operate fully automated, technically sophisticated mechatronic equipment.

This guide to all things related to CNC machining will walk through how modern CNC machining processes work, including material options, design considerations, cost drivers, and more. Today, there are several technical processes included underneath the CNC machining umbrella.

11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame)

power down junction box 47b

power distribution box ford e350

I use a 4 1/8 hole saw for both cut in plastic and metal octagonal and fan boxes. A 4 inch leaves a little trimming to be done with the plastic boxes where the tabs are, no problem with sheetrock, just push it in, a little tougher with lath and plaster.I need to cut several holes in the ceiling for a 4 inch round Old Work Box (Carlon Blue 18cu). What size hole saw would I need? Yes, I know I can do it with a keyhole saw, but rather just spend the $ and get the hole saw and be done with it.

basics of cnc machine pdf|cnc machine drawing PDF