diy aluminum metal electronics project enclosure Build a custom enclosure for your electronic projects. Learn how to build enclosures with Aluminum Extrusion. You MUST NOT enter a box junction unless your exit road is clear. But you can enter the box when you want to turn right and you’re only prevented from doing so by oncoming traffic.

0 · electronics project enclosure design

1 · diy electronics enclosure

2 · diy aluminum enclosures

3 · aluminum enclosure plans

4 · aluminum enclosure for electronic design

5 · aluminum enclosure construction

6 · aluminium enclosures for electronic projects

7 · aluminium enclosure design

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings.

I will show you how I mounted and wired electronics inside an electrical box as well as how I mounted buttons, switches, and connectors on the outside of the . Build a custom enclosure for your electronic projects. Learn how to build enclosures with Aluminum Extrusion.Cheval Multipurpose Aluminum Enclosure Heatsink DIY Project Box (Aluminum and Aluminum extrude Enclosure with Mount bar (2U) 86 x 200 x 200 mm.), Black.99

electronics project enclosure design

diy electronics enclosure

Sunetec provide some high metal boxes for multi-purpose project. You can use this custom enclosures for your DIY project. It's an mild steel cover with aluminum base that stylish look .

Creating the perfect enclosure is an important step in finishing any electronics project. It keeps your circuit safe while improving the function and look of your project! Here are a few different ways to make your own. ALUMINUM ALLOY PROJECTOR BOX - Made of high quality aluminum alloy material, durable and long service life. DIY ENCLOSURE . Using an off-the-shelf electronics enclosure, sometimes referred to as a project box, is the most straightforward option for many makers and projects. Pre-made cases come ..90

4.007.58 What kind of material of electronic enclosure I should choose? Plastic or Aluminum electronic enclosure? How I design and make my own electronic enclosure? This guide would solve all your problems!

diy aluminum enclosures

Want to make electronics project boxes but not sure where to start? This is your guide for electronics enclosure design, materials & custom cases.

After some brainstorming, I found out that I can build enclosures with extrusion used for aluminum fabrication, which is cheap to buy at a Local hardware shop,I will show you how I mounted and wired electronics inside an electrical box as well as how I mounted buttons, switches, and connectors on the outside of the box. All of this can be done with a simple outdoor electrical box from a hardware store.

Build a custom enclosure for your electronic projects. Learn how to build enclosures with Aluminum Extrusion.

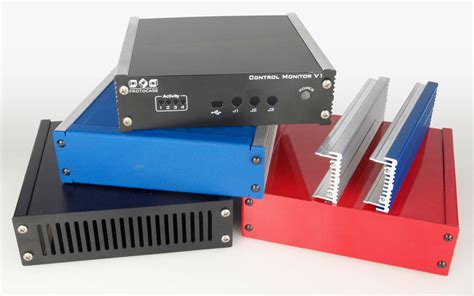

Cheval Multipurpose Aluminum Enclosure Heatsink DIY Project Box (Aluminum and Aluminum extrude Enclosure with Mount bar (2U) 86 x 200 x 200 mm.), BlackSunetec provide some high metal boxes for multi-purpose project. You can use this custom enclosures for your DIY project. It's an mild steel cover with aluminum base that stylish look shape & construction design are professional. Creating the perfect enclosure is an important step in finishing any electronics project. It keeps your circuit safe while improving the function and look of your project! Here are a few different ways to make your own. ALUMINUM ALLOY PROJECTOR BOX - Made of high quality aluminum alloy material, durable and long service life. DIY ENCLOSURE CASE - Adopt split type design, you can assemble and design the box you want by yourself. PREMIUM QUALITY - Surface sandblasting and brushed treatment, wear resistant and beautiful, comfortable hand feeling.

Using an off-the-shelf electronics enclosure, sometimes referred to as a project box, is the most straightforward option for many makers and projects. Pre-made cases come in all shapes and colors, and you can often also choose materials specifically tailored to different project environments. What kind of material of electronic enclosure I should choose? Plastic or Aluminum electronic enclosure? How I design and make my own electronic enclosure? This guide would solve all your problems! Want to make electronics project boxes but not sure where to start? This is your guide for electronics enclosure design, materials & custom cases.After some brainstorming, I found out that I can build enclosures with extrusion used for aluminum fabrication, which is cheap to buy at a Local hardware shop,

I will show you how I mounted and wired electronics inside an electrical box as well as how I mounted buttons, switches, and connectors on the outside of the box. All of this can be done with a simple outdoor electrical box from a hardware store. Build a custom enclosure for your electronic projects. Learn how to build enclosures with Aluminum Extrusion.Cheval Multipurpose Aluminum Enclosure Heatsink DIY Project Box (Aluminum and Aluminum extrude Enclosure with Mount bar (2U) 86 x 200 x 200 mm.), BlackSunetec provide some high metal boxes for multi-purpose project. You can use this custom enclosures for your DIY project. It's an mild steel cover with aluminum base that stylish look shape & construction design are professional.

Creating the perfect enclosure is an important step in finishing any electronics project. It keeps your circuit safe while improving the function and look of your project! Here are a few different ways to make your own. ALUMINUM ALLOY PROJECTOR BOX - Made of high quality aluminum alloy material, durable and long service life. DIY ENCLOSURE CASE - Adopt split type design, you can assemble and design the box you want by yourself. PREMIUM QUALITY - Surface sandblasting and brushed treatment, wear resistant and beautiful, comfortable hand feeling.

Using an off-the-shelf electronics enclosure, sometimes referred to as a project box, is the most straightforward option for many makers and projects. Pre-made cases come in all shapes and colors, and you can often also choose materials specifically tailored to different project environments.

To make this safe, the limited approach boundary is blocked off with caution tape, the doors left open and usually a fan is set up to move some air around. The best I can find is OSHA 1926.403 (i) (2) . But this is focused around construction guidelines so .

diy aluminum metal electronics project enclosure|aluminium enclosures for electronic projects