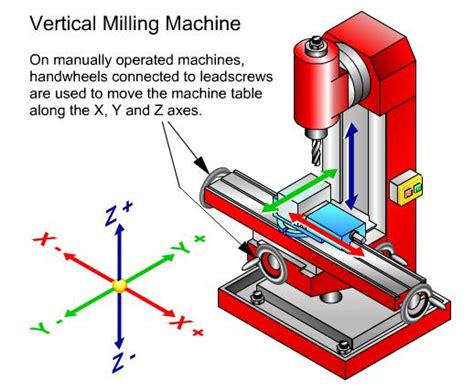

an axis of travel on a cnc machine is 3-Axis CNC Machining. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes. What is the metal thing boxers use on their face? The Enswell Eye Iron – The ‘must have’ item for any established boxing cutman. The Enswell is kept on ice before and throughout the fight. It’s then used to treat facial cuts and bruises throughout a fight, by reducing swelling and decreasing blood flow to the affected area.

0 · milling machine axis diagram

1 · machining lathe axis diagram

2 · cnc mill axis diagram

3 · cnc machine axis locations diagram

4 · cnc lathe axis diagram

5 · cnc axis chart

6 · axis on cnc lathe

7 · axis identification in cnc machine

A gauge conversion chart can be used to determine the actual thickness of sheet metal in inches or millimeters. For example, 18 gauge steel, according to a gauge conversion chart, is 0.0478 inch or 1.214 millimeter.

milling machine axis diagram

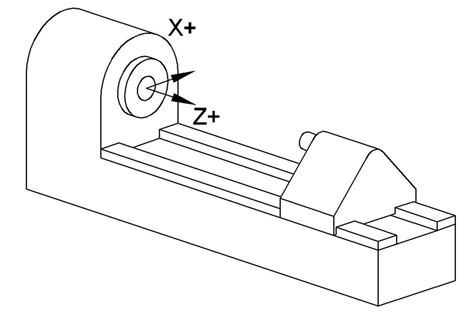

The most common configuration for a CNC lathe is two-axis, known as X-axis and Z-axis. The X-axis is the horizontal axis, which runs parallel to the lathe spindle. This axis controls the longitudinal movement of the cutting . Using an X, Y or Z code in a CNC program tells the machine to go to a specific location along those axes. Location changes can be in one or more axes. If only a Z axis .

machining lathe axis diagram

If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping.

Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even .

3-Axis CNC Machining. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.

A 5-axis CNC milling machine also includes an axis of rotation around the X-axis – the A-axis, and a rotation axis around the Z-axis – the C-axis. The rotation axis is realized by a servo motor through a precision reducer, and .

Four axes on a CNC machine add an extra cutting direction, which increases precision. The fifth axis further improves the accuracy of the machine, but the cost of the five-axis CNC machine makes it too expensive for . 3 Axis CNC Machine. A 3-axis machine is capable of moving independently in three directions, not including the rotation of the spindle itself. Every axis of travel means an additional degree of freedom for the machine’s .

So here is the CNC axes directions convention: The spindle is ALWAYS the Z axis. The right hand rule is used to determine the linear axes and their direction. The middle finger is the Z axis, the thumb the X axis, and index .

cnc mill axis diagram

2-Axis CNC Machines. As the name suggests, the 2-axis CNC machine has moving components that travel along two axes. Depending on the type of machine and the work envelope’s orientation (i.e., horizontal or vertical), these two axes can be a combination of the x-axis and y-axis, the x-axis and z-axis, or the y-axis and the z-axis. The most common configuration for a CNC lathe is two-axis, known as X-axis and Z-axis. The X-axis is the horizontal axis, which runs parallel to the lathe spindle. This axis controls the longitudinal movement of the cutting tool, allowing it . Using an X, Y or Z code in a CNC program tells the machine to go to a specific location along those axes. Location changes can be in one or more axes. If only a Z axis coordinate is given then the machine will only move in the Z axis. This is .If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping.

Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even controlling more than 10 axes.3-Axis CNC Machining. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes. A 5-axis CNC milling machine also includes an axis of rotation around the X-axis – the A-axis, and a rotation axis around the Z-axis – the C-axis. The rotation axis is realized by a servo motor through a precision reducer, and the accuracy can reach one ten-thousandth to one hundred thousandths of a degree.

Four axes on a CNC machine add an extra cutting direction, which increases precision. The fifth axis further improves the accuracy of the machine, but the cost of the five-axis CNC machine makes it too expensive for most businesses.

3 Axis CNC Machine. A 3-axis machine is capable of moving independently in three directions, not including the rotation of the spindle itself. Every axis of travel means an additional degree of freedom for the machine’s movement, and that translates into the ability to make more complex shapes.

lowes sheet metal flashing

cnc machine axis locations diagram

cnc lathe axis diagram

cnc axis chart

A boxplot, also known as a box plot, box plots, or box-and-whisker plot, is a standardized way of displaying the distribution of a data set based on its five-number summary .

an axis of travel on a cnc machine is|cnc axis chart