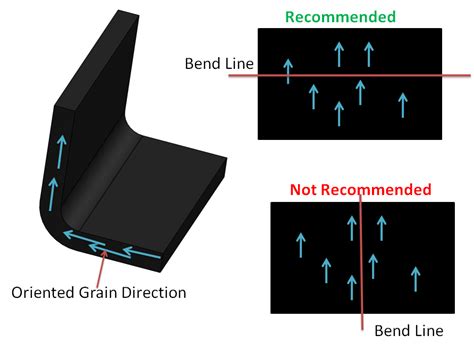

grain direction in sheet metal bending Materials with a grain direction that affect the bend angle are considered anisotropic. Materials that don’t have this property are considered isotropic. FIGURE 1. Bends made with the grain (that is, the bend line runs parallel to the grain direction) have a greater . If you look inside the box where the switch is, you'll see that it is connected between the black and red wires. When the switch is off, the red wire is not connected to anything at all, so it shows .

0 · grain direction on sheet metal

1 · grain direction metal bending

2 · grain bending techniques

3 · grain bending sheet metal

4 · bending parallel to sheet metal

5 · bending metal with grain

6 · bending across sheet metal

7 · bending across a grain

Since emerging as a symbol of Remembrance after the First World War, poppies worn during the Poppy Appeal have come in a range of shapes and sizes. From handmade silk and cotton poppies to the new plastic-free poppy made entirely from paper, discover how the poppy has evolved over the last century.

Materials with a grain direction that affect the bend angle are considered anisotropic. Materials that don’t have this property are considered isotropic. FIGURE 1. Bends made with the grain (that is, the bend line runs parallel to the grain direction) have a greater .Like the grain in wood, a metal’s grain affects how the piece behaves. Varying .Grain Direction in Metal Bending. When working with plate, pay close attention to . Grain Direction in Metal Bending. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see Figure 1). A plate’s grain direction comes .

Learn about grain orientation and its impact on forming sheet metal. Find out the implications of bending with or against the grain for crack manifestation.

The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. This is because grain direction makes sheet . In general the structure of the normalised plate is finer. Plate bending can be split into two main categories, plate rolling and press braking. The latter consists of much tighter radii, therefore the risk of fracture is much .

Grain Direction: align the bend line with the metal grain to reduce the risk of cracking. Bend Angle Accuracy: consider the material's springback characteristics to achieve .Pre-Bend Considerations: Grain Direction and Bend Radius. Before bending, consider the grain direction, as bending along the grain can result in cracks. Similarly, ensure the bend radius is appropriate for the thickness and type of . When polycrystalline materials are being bent through methods like those using a press brake, the direction of the grain running through the material becomes critical. A common way to prevent material failure or . Grain Direction. During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers. 8. Grain Size. Grain within the material influences .

grain direction on sheet metal

The Effect Of Grain Direction In Sheet Metal Bending.For Press tool Design and Other course visit : https://industrylearning.co.in/courses/press-tool-design-nx/ Hi Friends,In this video you will learn Introduction to sheet metal process | Grain direction | Bend allowance & K-factor | Spring backCheck out other videos.If you use the sheet metal tools in Solidworks (or most other CAD software), some of the cuts and notches are generated kind of automatically when you bend a side, etc. . We give flat pattern extents with taps or csinks because theyre .

Sheet metal with an average yield strength of 41,000 PSI can be sold as A36 steel, even though it is 13 percent harder than 36,000-PSI steel. . the results of bending will change in relation to the grain. Bending with, against, or diagonal to the grain direction will produce different bend angles and inside bend radii, all requiring different . Mistakes Which Should be Avoided. Minimum Bend Radius: Neglecting the recommended minimum bend radius may result in metal cracking and structural weakening. Material Grain Direction: Tripods Sustain submitted the reason that it can fracture if it is bent against the grain. Corner Relief: The absence of appropriate corner relief means the metal .The grain structure of sheet metal gets aligned in the rolling direction during the cold rolling operation. When bending soft materials in the rolling direction cracks may appear. Therefore bending in the direction perpendicular to the rolling direction is always preferred. Don't let sheet metal bending problems slow you down. Our guide offers 12 practical solutions to common issues, so you can achieve precise bends and quality results every time. . Crystal Structure and Rolling Grain Direction: Sheet metal has a specific crystal structure and rolling grain direction. Bending parallel to the grain direction .

This paper reviews the various parameters affecting spring back such as punch angle, grain direction of sheet metal material, die opening, ratio of die radius to sheet thickness, sheet thickness .

However, more precision requires greater consistency in the tooling setup for blanking and bending the sheet metal parts. As raw material, sheet metal has behavioral weirdness. Some of that weirdness, stress in particular, is relieved during manufacturing. . When specifying a grain direction, perpendicular to the bend is structurally the best .

Explore top sheet metal design tips for optimal bending. Dive into techniques, common mistakes, and best practices to master the art of metal shaping. . resulting from their manufacturing process. When bending, always take this grain into account. Bending parallel to the grain direction reduces the risk of cracking while bending against it . Tools Used in Sheet Metal Bending. Bending of sheet metal requires a lot of tools that are very specific in the design, and also, the bending can be done very well. . While deciding on the appropriate bend orientation, the grain direction of the material, bend allowance, and tooling restrictions must be considered. If bends are made with the .

fabrica de globos metalicos mayoreo

In the field of metalworking, where precision and durability reign supreme, metal bending is a complex but essential technique. Forging steel plates into complex, sturdy shapes requires a harmonious blend of artistry and mechanical finesse. . Pay attention to the grain direction: The grain direction of the steel affects its bending .2024-10-23. The effects of austenite grain size on the deformed microstructure and mechanical properties of an Fe–20Mn–6Al–0.In terms of expected results, obviously it is harder to produce impact toughness longitudinally because the grain direction of the steel provides a natural resistance to fracture.Schlagwörter:Metal Grain StructureAluminum Grain .Since sheet metal is rolled out and cut down into smaller sections, it is possible that the long dimension of a large blank will be the grain direction. Looking at the surface of a piece of metal, any subtle irregularities or lines should indicate the direction of the grain, though a magnifying glass or even a microscope may be needed.

fabric with silver metal

For example, if the grain flow is in the same direction as the bending force, the part will be much stronger than if the grain flow is in the opposite direction. Grain size and direction can also affect the surface finish and formability of sheet . Sheet metal bending is an Art: kearn everything on material selection, bend radius, grain direction, how to avoid springback, warping, inaccurate angles. Press Brakes Hydraulic Press BrakesDuring sheet metal processing ( rolling operation), material grain arranges in the direction of rolling. The material grain rearranges when Sheetmetal is bent perpendicular to the rolling direction. That has a negligible impact on part .

The common bending methods on the press brake are air forming (or air bending), bottoming (or bottom bending), and coining. 6. Bend Length. The length of the bend is proportional to the tonnage required to make the bend. 7. Grain Direction. During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set . Always consider the grain direction when laying out parts on a sheet, as it impacts the metal’s bending and forming characteristics. Identify the grain direction on the provided material stock, which is often indicated by the rolling direction or by markings from the supplier. In the case of C385 brass sheet, the mechanical and physical properties such as strength and ductility depend on the bend’s orientation with respect to the grain direction. The grain boundaries can affect the material’s response to applied forces.Display sheet metal bend notes: Displays bend notes in the drawing. In Style, select the location for the bend notes. You can also right-click a . Show grain direction: Displays the grain direction that is defined in the flat pattern feature of the sheet metal part. To view the grain direction, the flat pattern view must include a bend table. .

Master the art of bending sheet metal with Shengen, a B2B sheet metal parts manufacturer. Learn basics, advanced techniques, and safety tips. Capabilities. . Bending against the grain direction. Using the wrong bend radius. These mistakes can lead to defects like cracks, inaccurate bends, and deformations in the metal. . Direction of metal grain; Material chemical and mechanical properties; Section 2 Material Thickness. Variations in material thickness are one of the most common challenges when achieving bending tolerances. Sheet metal can have variations in thickness throughout a single sheet or between sheets. The nature of the rolling process often means .

grain direction metal bending

Analyzing the k-factor in sheet metal bending A deep dive into the k-factor, what it is, and why it matters. By Steve Benson; Updated October 20, 2023; September 12, 2018; . This is made worse when the bend line is parallel to the grain or rolling direction of the sheet metal. If the bend in a given piece of metal is bent with a sharp punch . I am assuming the grain would run the long 8' direction of a sheet 4' x 8' I need to bend the parts across the grain and the material has not shown up yet but I want to nest the parts in the sheet. Sorry for the dumb question I have had these parts cut in the past by someone else with a waterjet. Grain Direction and the Bend Line. The sheet or plate material is the weak link in forming. We should always consider as many material variables as possible before we commit a project for production. . Steve Benson is a member and former chair of the Precision Sheet Metal Technology Council of the Fabricators & Manufacturers Association . Roll bending is a type of sheet metal bending that uses three rollers to bend sheet metal into a cylindrical shape. The rollers are arranged in a pyramid configuration, and the sheet metal is passed through them. The rollers rotate in the same direction and at different speeds, which causes the sheet metal to bend into a cylindrical shape.

grain bending techniques

As far as I can tell plastic boxes are an inferior box once installed, but plastic are easier/faster to install than metal. For example plastic boxes often have built in nails and romex clamps, while metal boxes lack both.

grain direction in sheet metal bending|bending across sheet metal