blank in sheet metal Specialized tool steel, known as a blanking die, is used to cut metal out. This die is custom-made to punch out the desired shape from the metal sheet and is installed in a metal .

With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders.

0 · metal blanks for laser engraving

1 · blanking operation in sheet metal

2 · blank size calculator sheet metal

3 · blank reflective metal signs

4 · 8x10 metal sign blank

5 · 4x8 metal sign blanks

6 · 36x36 metal sign blank

7 · 10 round metal sign blanks

Working with Zinc Profiling and folding zinc. As zinc is a rolled metal it has a rolling direction, which is also indicated on the protective film. It is recommended that this direction is respected on a roof or wall as light will reflect differently on panels laid in opposite directions.

From the basics of metal blanking to advanced techniques, this guide covers it all. Learn about the equipment used, materials processed, and applications of metal blanking. .The Sheet Metal Blanking Process – Step-by-Step Selection Sheet Metal Material Exam. Each project thoroughly analyzes the sheet metal types, considering strength, elasticity, and corrosion resistance characteristics.

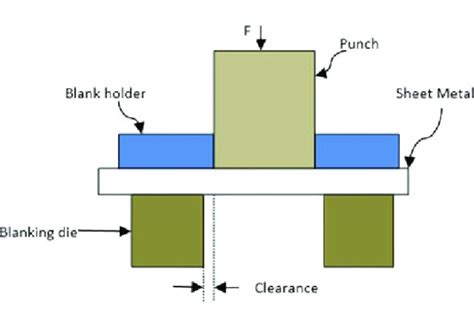

Blanking also utilizes a punch-and-die system. However, the blanking die opening is comparatively larger to accommodate the finished product. The clearance between punch and die blanking tool must be .

Sheet metal blanking is a critical process in metal fabrication that involves the cutting or shearing of a shape from a metal sheet. This method plays a significant role in industries such as automotive, aerospace, and .Blanking is a crucial sheet metal fabrication process that involves cutting a flat sheet to create a flat piece or blank of specific shape and size. This process is essential in the early stages of .

Specialized tool steel, known as a blanking die, is used to cut metal out. This die is custom-made to punch out the desired shape from the metal sheet and is installed in a metal .Minifaber performs metal blanking on iron, aluminum, copper, stainless steel and special alloys sheets with maximum precision and advanced technology. Metal blanking involves shaping sheet metal using punches, which deform and cut, .

metal blanks for laser engraving

Punching blanking and piercing are sheet metal shearing operations to modify existing blank. Similar machines but different punch and die are used to perform these operations. In this article, we will discuss how blanking punching, and piercing operations are different from one another.

Sheet metal blanking results in blanks with imperfections of rough edges called burrs which affect part quality, functionality and are unsafe. Deburring enables you to remove these imperfections to ensure product quality, functionality and safety in use. From the basics of metal blanking to advanced techniques, this guide covers it all. Learn about the equipment used, materials processed, and applications of metal blanking. Read on for the ultimate guide.

The Sheet Metal Blanking Process – Step-by-Step Selection Sheet Metal Material Exam. Each project thoroughly analyzes the sheet metal types, considering strength, elasticity, and corrosion resistance characteristics.

Blanking also utilizes a punch-and-die system. However, the blanking die opening is comparatively larger to accommodate the finished product. The clearance between punch and die blanking tool must be substantial to achieve neat edges on the blank. Custom sheet metal manufacturers guide industries in choosing appropriate die openings and .

blanking operation in sheet metal

Sheet metal blanking is a critical process in metal fabrication that involves the cutting or shearing of a shape from a metal sheet. This method plays a significant role in industries such as automotive, aerospace, and construction, .

Blanking is a crucial sheet metal fabrication process that involves cutting a flat sheet to create a flat piece or blank of specific shape and size. This process is essential in the early stages of manufacturing, providing the foundation for subsequent forming, bending, or other processes. Specialized tool steel, known as a blanking die, is used to cut metal out. This die is custom-made to punch out the desired shape from the metal sheet and is installed in a metal stamping process. The die consists of two main parts: the punch and the die cavity.

Minifaber performs metal blanking on iron, aluminum, copper, stainless steel and special alloys sheets with maximum precision and advanced technology. Metal blanking involves shaping sheet metal using punches, which deform and cut, and dies, which give the shape.Blanking is a metal production process, during which a metal workpiece is removed from the primary metal strip or sheet when it is punched. The material that is removed is the new metal workpiece or blank. A die cut edge normally has four areas.

Punching blanking and piercing are sheet metal shearing operations to modify existing blank. Similar machines but different punch and die are used to perform these operations. In this article, we will discuss how blanking punching, and piercing operations are different from one another. Sheet metal blanking results in blanks with imperfections of rough edges called burrs which affect part quality, functionality and are unsafe. Deburring enables you to remove these imperfections to ensure product quality, functionality and safety in use.

From the basics of metal blanking to advanced techniques, this guide covers it all. Learn about the equipment used, materials processed, and applications of metal blanking. Read on for the ultimate guide.The Sheet Metal Blanking Process – Step-by-Step Selection Sheet Metal Material Exam. Each project thoroughly analyzes the sheet metal types, considering strength, elasticity, and corrosion resistance characteristics. Blanking also utilizes a punch-and-die system. However, the blanking die opening is comparatively larger to accommodate the finished product. The clearance between punch and die blanking tool must be substantial to achieve neat edges on the blank. Custom sheet metal manufacturers guide industries in choosing appropriate die openings and . Sheet metal blanking is a critical process in metal fabrication that involves the cutting or shearing of a shape from a metal sheet. This method plays a significant role in industries such as automotive, aerospace, and construction, .

blank size calculator sheet metal

Blanking is a crucial sheet metal fabrication process that involves cutting a flat sheet to create a flat piece or blank of specific shape and size. This process is essential in the early stages of manufacturing, providing the foundation for subsequent forming, bending, or other processes. Specialized tool steel, known as a blanking die, is used to cut metal out. This die is custom-made to punch out the desired shape from the metal sheet and is installed in a metal stamping process. The die consists of two main parts: the punch and the die cavity.

Minifaber performs metal blanking on iron, aluminum, copper, stainless steel and special alloys sheets with maximum precision and advanced technology. Metal blanking involves shaping sheet metal using punches, which deform and cut, and dies, which give the shape.

electrical boxes for wall sconces

electrical boxes for under table applications

Enhance your bird feeding station with the Woodlink Metal Oriole Jelly and Orange Feeder, designed to attract vibrant orioles with its versatile feeding options and durable construction. Versatile Feeding Options: Holds 2+ orange halves and includes a glass dish for jelly, offering a variety of treats to entice orioles and other fruit-loving birds.

blank in sheet metal|10 round metal sign blanks