sheet metal fabrication bending Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a . Browse photos of porches to get inspiration for your own remodel. Discover porch decor and railing ideas, as well as layout and cover options.

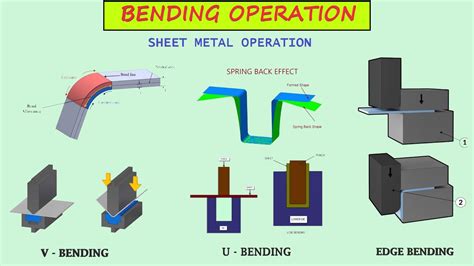

0 · types of sheet metal bending

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending basics

5 · bending sheet metal by hand

6 · bending sheet metal at home

7 · bending galvanized sheet metal

Our list of recommendations covers the various materials used in the most popular bread boxes, including metal, plastic, bamboo, and other types of wood. Depending on .

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a .

Experience unparalleled precision and innovation with TAIWA, your trusted custom sheet metal fabricator. From laser cutting to metal bending and forming, our state-of-the-art Japanese equipment ensures impeccable quality. We offer .

Top 10 Best Sheet Metal Fabrication in San Jose, CA - November 2024 - Yelp - Fusion Welding, A & J Precision Sheetmetal., Odie Sheet Metal, Custom Metal Manufacturing Company, Kc Sheetmetal, Acosta Sheet Metal Mfg, Industrial Metal Service, Nick's Machining, Superior Roof Metals, Vander-Bend Precision Sheetmetal Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost .Sheet metal forming techniques include bending, stamping, stretching, rolling, and deep drawing. . Sheet metal fabrication’s vast construction applications are due to the durability, strength, high weather resistance, manufacturability, versatility, aesthetic qualities, and other beneficial properties of various sheet metals, including .Best Metal Fabricators in Bend, OR - JC Precision Welding, Advanced Northwest Welding, Bend Heating & Sheet Metal, CLS Fabrication, Jon Small Welding, J Bar Metal Fabrication, Simply Fabricated, SC Welds, All Weld, Bend Machine . Bend Heating & Sheet Metal. 4.2 (17 reviews) Heating & Air Conditioning/HVAC Metal Fabricators.

types of sheet metal bending

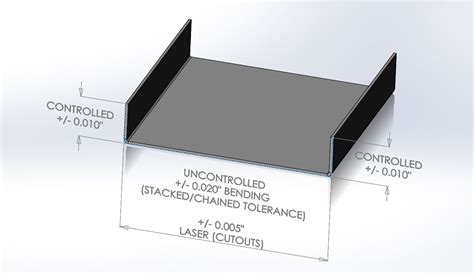

Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000. . When bending sheet metal, it’s impossible to create a completely sharp corner. There will always be a slight curve which is .

Discover key terms and the different techniques for precise sheet metal bending in our comprehensive guide. Learn the tips & tools for bending sheet metal. 919-231-8648 [email protected] Request a Quote. Home; About. . making it crucial to understand the differences for successful sheet metal fabrication. Learn more about each method below.Manufacturer of Sheet Metal Fabrication Service - CNC Bending Services, Sheet Metal Fabrication Services, Sheet Metal Bending and Shearing Service and Sheet Metal Components Job Work offered by Exilon Industries, Greater Noida, Uttar Pradesh.

In sheet metal bending, you work a flat metal piece by applying a force that deforms it along a straight axis. The result is an angular change in shape allowing you to form curved and angled parts. . Changing metal sheet thickness results in inconsistent bend angles. Applications. General fabrication requiring multiple bends with different .Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight

sheet metal bending standards

Sheet metal bending involves applying varying levels and degrees of force to a piece of metal to form/shape/bend it into a desired structure. Of course, the sheet metal may go through several other fabrication processes as well as bending, and you can read more about these processes on our services pages online.. In fabrication, often the bending process .

We’re your single-source supplier for sheet metal cutting, bending, fabricating, and welding services. Request A Quote CAMM Metals is a single-source supplier of metal fabricated parts, components, and assemblies. Founded in 1996, we have a long-standing record of producing high-quality parts with excellent customer service. Our capabilities . Bump forming also known as bump bending, step bending, or repetitive v-bending, is a popular sheet metal fabrication art of bending sheet metal materials into desirable cylindrical or conical shapes for different industry applications using a press brake.. In this article, we provide a comprehensive guide on sheet metal bump bending with details on the suitable metals you .Bending is one of the popular and essential sheet metal bending services fabrication operations in the metal manufacturing industry. For instance, metal bending plays an important role in the automotive business because they use various shapes to have an accurate automobile part that goes perfectly with their design. The process of bending .Your go-to welding Bend Oregon company! For inquiries call (541) 325-8543.

sheet metal bending near me

Mistakes Which Should be Avoided. Minimum Bend Radius: Neglecting the recommended minimum bend radius may result in metal cracking and structural weakening. Material Grain Direction: Tripods Sustain submitted the reason that it can fracture if it is bent against the grain. Corner Relief: The absence of appropriate corner relief means the metal .Twin City Sheet Metal, located in Brewer, Maine, offers customers throughout Maine design, fabrication and installation of sheet metal products including ductwork. 26 Coffin Avenue. Brewer, Maine (207) 990-5605. Tel: 207-990 .

Sheet metal fabrication takes thin, flat, and bendable sheets of different types of metal and cuts, bends, and assembles them into a variety of products. 9/2/2021. PDF File. Sheet Metal Fabrication. . Bending sheet metal makes it possible to create a wide variety of part geometries. The angle and location of the bend can be precisely .With two expansive sheet metal fabrication factories and a dedicated team of over 90 specialists, we at Shengen stand at the forefront of the industry. Our in-house expertise allows us to handle any project, no matter the size or complexity.

In sheet metal bending calculations, the impact of different material types on the bending factor is significant and multifaceted, influencing the accuracy, quality, and efficiency of the bending process. . This article demystifies the crucial role of fabrication holes in sheet metal bending. You'll learn how these holes.

V-bending is a form of sheet metal fabrication that uses a V-shaped die to bend the material into a curved shape. This tool can be used to create many different kinds of bends, including 90-degree angles, curves, and more.KDM offers sheet metal fabrication for producing different products, structures, and parts. We can provide different fabrication processes including stamping, welding, bending, assembly, laser cutting, and more.Our engineers can bend, fold, or cut different sheet metal materials to .Curved sheet metals. Image credit: https://kdmfab.com Curved sheet metal is another method of sheet metal bending used to create more complex curved shapes and designs. It involves creating a curved bend in a sheet metal using a press brake or rollers. The press brake uses a die and punch to create the desired bend, while the rollers use a series of rollers to shape the metal. Bending Techniques in Sheet Metal Fabrication. Bending is a fundamental and the most important process in sheet metal fabrication, enabling the creation of three-dimensional shapes from flat sheets. This process involves applying force to .

Twin City Sheet Metal, located in Brewer, Maine, offers customers throughout Maine design, fabrication and installation of sheet metal products including ductwork. 26 Coffin Avenue. Brewer, Maine (207) 990-5605. Tel: 207-990-5605 . Our Cincinnati CNC 5-axis press brake makes metal bending a consistent and accurate process across all sheet . Sheet metal fabrication machines can be categorized into four main types: cutting machines, forming and bending machines, machining and drilling machines, and specialized machines. Cutting Machines. . Press Brakes: Press brakes are used to bend and shape sheet metal. They utilize a punch and die system to apply force and create bends or folds .

sheet metal bending guidelines

sheet metal bending basics

bending sheet metal by hand

Check out our wooden electric box cover selection for the very best in unique or custom, handmade pieces from our wall hangings shops.

sheet metal fabrication bending|sheet metal bending near me