cnc milling part drawing In the fast-paced world of CNC machining, the distinction between drawing parts, production parts and special parts plays a crucial role in optimizing production efficiency. CNC24 uses advanced technologies and in-depth industry knowledge to ensure that all processes are efficiently designed and state of the art.

If your project needs electrical boxes or enclosures, and you don’t know what are the main types of electrical enclosures, you need to read this guide, I will tell you 76 types of electrical boxes for your business based on material, .

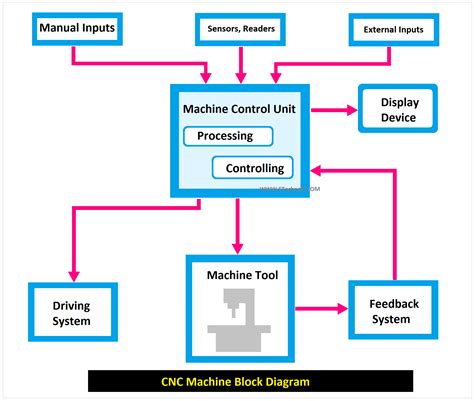

0 · schematic diagram of cnc machine

1 · milling machine parts diagram

2 · homemade cnc parts

3 · cnc milling machine parts names

4 · cnc mill parts diagram

5 · cnc mill diagram

6 · cnc machine parts list pdf

7 · cnc horizontal milling for dummies

Multi-chapter guide to Metal Mesh describing: the types, applications, materials, weave patterns, benefits and applications of metal mesh.

Drawing for CNC machines is an essential skill for anyone involved in computer numerical control (CNC) machining. Whether you are a beginner or an experienced professional, it is important .

It is compulsory to indicate and define threads on the drawing for CNC machining if your parts contain them. You should define these threads by indicating a standard thread size like M4x0.7 instead of a diameter dimension. . The document provides information on profile milling and contains 6 examples of CNC part programs for milling various components. The programs use G-code commands like G00, G01, G02, G03 as well as M-codes to . So, it would help if you had good experience reading engineering drawings to design accurate machining parts. Table of Content Methods of reading engineering designs for CNC turning Machining Parts 1: First, look at .

A very simple cnc milling machine programming tutorial for beginner level cnc machinists. A cnc g code example without the use of any cnc canned cycle. . Although this example drawing looks a bit complex, but it is very easy to program. . For beginners it will be useful if they divide the drawing in some smaller parts and start programming . In the fast-paced world of CNC machining, the distinction between drawing parts, production parts and special parts plays a crucial role in optimizing production efficiency. CNC24 uses advanced technologies and in-depth industry knowledge to ensure that all processes are efficiently designed and state of the art.CNC machining outsourcing is a manufacturing strategy that involves contracting with another company for CNC machining services. Whether for prototyping or production, product designers who outsource their machined parts gain access to advanced technology, leverage custom machining solutions, and avoid expensive investments in equipment and .Find Cnc Milling Part stock images in HD and millions of other royalty-free stock photos, illustrations and vectors in the Shutterstock collection. Thousands of new, high-quality pictures added every day. Images. Images home; . 380 cnc milling part illustrations, drawings, stickers and clip-art are available royalty-free for download. .

In the modern world of CNC machining, manufacturing typically starts with a 3D CAD model created using a CAD 3D modelling software. Using CAM software, the 3D model is then converted to G-code, a machine language that CNC machines understand, and the machine produces the part from a block of material.Free download 42 best quality Cnc Milling Machine Drawing at GetDrawings. Search images from huge database containing over 1,250,000 drawings . 1000x1000 China Al 6061 T6 Anti Rotate Cnc Milling Part For Printer. 500x571 How To Use A Milling Machine. 605x564 Longitudinal Milling Complex Machine Frame Tom Tz25 Cnc Milling. 440x455 Milling .Protolabs CNC machining is a pretty competitive service for this kind of one-off. They have a bit of automated feedback and quoting and basically let you throw your design over the wall and get a machines part in the mail. . Creating a complete set of drawings is part of the learning process. The company I work for demands complete drawings .

Technical CNC drawings for CNC machining is a detailed, precise, and scaled representations of a part or component that will be manufactured using CNC machines. It includes information such as dimensions, tolerances, material specifications, and any other relevant details needed to accurately produce the part. These rigid and powerful machines consist of various parts that work in synchronization to perform the desired milling operation. Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of . Advanced CNC machining systems can read the geometry of a part directly from CAD, eliminating the need for additional documentation, such as technical drawings. However, while technical drawings aren't mandatory for requesting a CNC machining quote, they are still highly significant and commonly used in the manufacturing sector. In the modern world of CNC machining, manufacturing typically starts with a 3D CAD model created using a CAD 3D modelling software. Using CAM software, the 3D model is then converted to G-code, a machine language that CNC machines understand, and the machine produces the part from a block of material.

3. How to Prepare Technical Drawings for CNC Machining. When you are preparing technical drawings for CNC machining, it is important to follow these steps. Take a look at the following: First, you need to define the views .

You may want to know what makes technical drawing an integral part of CNC machining. This post aims to answer this question and more. Importance of a Technical Drawing Analyzed. Technical drawing or part design as a segment is very old and was done manually for centuries. Now, the process can be automated through design software.Common File Formats for CNC Turning Drawings . III. Understanding CNC Turning Drawing Standards . Introduction to Geometric Dimensioning and Tolerancing (GD\&T) ANSI and ISO Standards for CNC Turning Drawings . Interpretation of Symbols and Callouts in CNC Turning Drawings . IV. Steps to Create a CNC Turning Drawing . 1. Identifying the Part . A machining drawing is a type of engineering drawing that contains machining. Specific information that is required to manufacture a part distinct characteristics of a machining drawing that differentiate it from other types of engineering drawings include the material, size, weight information.

schematic diagram of cnc machine

By following these expert tips, you can master the art of preparing flawless technical drawings for CNC machining. These drawings act as the backbone of the manufacturing process, facilitating smooth communication between design and production teams and ultimately leading to high-quality, accurately manufactured parts.RALLY provides quality CNC milled parts services. Our custom design support ensures that each customer's unique vision is transformed into a tangible reality that maintains precision and conforms to specifications. In addition to initial production, RALLY offers specialized post-processing services ranging from anodizing for enhanced corrosion resistance to aesthetically .

Aluminum alloy parts cnc machining process. One-stop cnc milling and cnc turning service. Drawing or sample based metal customization service.

Apply basic machining skills per industry standards • • Demonstrate the basic math skills essential to CNC machining • Identify and utilize measuring tools that are basic to CNC machining • Interpret and apply information from prints and drawings • Measure part to nearest +/- .001" Demonstrate safe working practices on machinesIn the world of engineering, a 2D drawing or engineering drawing is a type of technical drawing that conveys information about a part, such as its geometry, dimensions, and acceptable tolerance. Unlike a digital CAD file, which represents an unmade part in three dimensions, an engineering drawing represents the part in two dimensions.− Set up, program, and operate a CNC mill or machining center and manufacture a part within tolerance − Work from a process sheet and part print. − Understand the x, y, z Cartesian coordinate system. − Create a tool set up sheet. − Understand fundamental machine processing, feeds and speed, and select simple part. Performance Standard

6 Packaging Methods for Metals CNC Milling Parts . We draw the drawings to better understand the names, tolerances, dimensions, part numbers and surface treatment process requirements of CNC parts drawings. Production is . 6. Part programming 1. Part programming consists of a sequence of instructions to be performed on the NC/CNC machine. 2. This are two types 1.Manual part programming. 2.Computer – aided part programming. CNC 3. In order to prepare part programming the programmer decides the order of the machining operations required to produce a component. . CAD is the initial step in the design process, creating a blueprint for the part. CNC follows by using this blueprint to manufacture the part. Technical Drawings for CNC Machining . Technical drawings are essential for translating design concepts into manufactured products. Key components of CNC technical drawings include: Title Block

milling machine parts diagram

ammo box sheet metal thickness

amerock 2 in diameter mushroom cabinet knob stainless steel

homemade cnc parts

Find the proper measurement for your gauge size. This chart compares gage numbers to their steel and aluminum sizing standards.

cnc milling part drawing|cnc mill parts diagram