where to connect ground wire time warner junction box After connecting the wires, secure them neatly inside the junction box. Additionally, if the box is made of metal, ensure proper grounding by connecting a ground wire to the grounding screw provided in the box.

Cable and junction box schedules are documents prepared by instrumentation and control engineers that list cables and junction boxes needed for a project. The cable schedule includes cable numbers, types, sizes, lengths and termination details.

0 · metal junction boxes grounding

1 · metal junction box grounding instructions

2 · how to ground a metal box

3 · ground wire connections in metal box

4 · basement metal junction box wiring

5 · 6 gauge junction box wiring

6 · 6 awg wire junction box

7 · 6 awg junction box grounding

What is Offset in CNC Machining? Offset in CNC machining refers to the adjustment made to the cutting tool's position during the machining process. It compensates for variations that may arise in tool size, workpiece dimensions, and machine accuracy. CNC machines rely on accurate offsets to ensure that the final part matches the intended design .

Currently reworking wires and adding new circuits. Upon opening junction boxes in my basement I found the bare ground wires connected to the metal box itself. Is this proper, or should the be pigtailed inside the box?

The ground wire coming with the supply cable should be securely connected to the box itself with a threaded machine screw. From there this ground should come out of the box and wire nutted to a wire from the screw . It allows you to bond up to 4AWG wire to the junction box without splicing or pigtailing the ground wire. You can fasten it to the JB with the existing grounding bonding screw in the box. From http://www.solar . In a junction box with about 12, and may grow to 20, cables of size #14, #12, #10 what is the best, and alternative connectors to join all the ground wires together? Can I install .

Nothing is more dangerous and aggravating than loose wires in a junction box. In this video you'll learn how to wire junction boxes correctly. You'll also see our favorite tools to. After connecting the wires, secure them neatly inside the junction box. Additionally, if the box is made of metal, ensure proper grounding by connecting a ground wire to the grounding screw provided in the box. Install the ground wire into a metal junction box. Connecting all the wires leaves you with one loose wire. This wire should be either green or copper-colored. Locate the ground screw inside the junction box, which must be . Note: If you’re working with a metal box, you’ll need to add a pigtail (a separate 4- to 6-inch length of ground wire) to the other grounds and connect it to the green ground screw located inside the box. Wrap the pigtail clockwise .

I will connect the black/blue wire from the fan to the black wire from the ceiling, and the white wire from the fan to the 3 twisted white wires from the ceiling. From what I've read, the reason that there are several white . He had me buy a 6/3 that now contains a black, red, white, and ground. Told me to connect the bare wire to the new white wire, black to black, black/red to red, and had me buy ground screws and caps. What do I do with . I have a 6" junction box with one 6 ga. wire for a 50 amp service. I'd like to "pigtail" this wire to two outlets.one for my welder and one for my plasma cutter. These units will not be used at the same time. Short of running another circuit, what's the best way to .

The typical thing to do is to use a pigtail to connect the switch ground terminal to the box and the ground wire. Absent a visible ground wire, you have to assume the ground is properly done and continuous all the way back to the panel. This .The ground wire coming from the metal junction box is very short and is secured by a screw in the back of the box. There is no extra slack to the wire that will allow me to connect it to the ground wire of the light fixture. There is another metal screw at the back of the junction box that is not connected to any wires. Can I wrap the ground .A ground wire is modern code but not necessary as you see in your older home ungrounded two wire system. Probably half the homes in the country and every home built before 1960's have an ungrounded two wire system unless it has been upgraded. Connecting a ground wire to an ungrounded box accomplished nothing.Deep inside the junction box is a bare copper wire (presumably ground). It was not attached to anything with the previous light fixture. My understanding is that all ground wires need to be connected. I am just not sure exactly where/in what order they should connect, or where they connect to the green ground screw on the mounting piece.

The instruction manual suggest connecting the light fixture's ground wire to the ground wire that's coming into the junction box with a wire nut. And if there's no grounding wire coming into the junction box, then connect the fixture's grounding wire to the grounding screw which makes contact to the metal junction boxthat's grounded (2007 build .

That wire was originally two hots plus neutral, presumably for a previous ungrounded oven or range, which was allowed at the time (both "no ground" and "bare neutral" on that type of circuit). Then someone put in gas and put in an illegal (assuming grounding required by that time, which is likely the case) receptacle using one of the hots and using the bare wire as both . The ground wire of the new cable would end at the junction boxes and be connected to nothing until such time as the old wiring sections were upgraded. An old section being re-energized with a new cable must have been completely isolated with its neutral also not connected to any other branch circuit at the far end. If you are using clamps, attach the clamp to the junction box and attach the grounding wire to the clamp. Step 4: Connect the Grounding Wire to the Electrical System Ground. If you are using a pigtail connector, strip away about 3/4 inch of insulation from the end of the grounding wire that is not attached to the junction box. Then, twist the .

metal junction boxes grounding

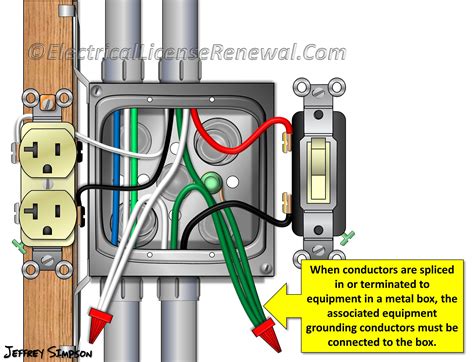

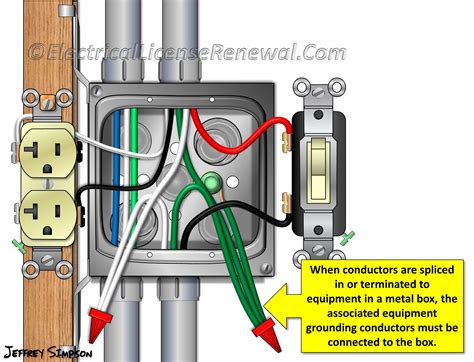

82K subscribers in the askanelectrician community. After a period of inactivity, this subreddit is under construction and will be available to the.250.148 Continuity and Attachment of Equipment Grounding Conductors to Boxes. Where circuit conductors are spliced within a box, or terminated on equipment within or supported by a box, any equipment grounding conductor(s) associated with those circuit conductors shall be connected within the box or to the box with devices suitable for the use in accordance with 250.148(A) .

What is the "right" way to join 7 different wires in a single electrical box? Here's the situation. I opened up a four-gang light switch. There were four switches controlling five lights. As expected, the four switches were interrupting the hot (black) wires. The neutral (white) wires also went through this box.

Should I take the time to fix it by adding a pigtail to connect the ground to the ground screw on the new outlets? electrical; . connector for 12 to 20 ground wires in a junction box? 5. Does every single ground wire in a box have to connect to every other ground wire within the confines of that same box on one branch circuit? You connect all the grounds together with a ground crimp connector. A wire nut is not sufficient to meet code. And then if the box is metal, you connect the crimped bundle to the box. Leave one of the ground wires longer than the others, sticking through the crimp connector, and attach that one to the box.My existing junction box has an old copper ground wire attached to an old rusted ground screw. I am supposed to take the new copper ground wire from the Ring light, secure it to a new green ground screw that is on the Ring light's .

A "smart" switch/etc. may also be particular about hot vs. switched hot, in which case you would need to figure out which black wire is which. As far as ground, the ground wire needs to connect to a screw in the box, and it .Most of the time fiber is used since it's a pain to properly ground UTP cable. If you couldn't do fiber, I'd have converted to coax for an outdoor run since that's easy to ground. Also if you note that box does NOT have a grounding screw like the actual metal box next to it used for high voltage. It's really just a weatherproof outdoor cover.You shouldn’t do this. It is dangerous to wire a junction box without a grounding wire. But people do so all the time. If that sounds like you, your options will include: 1). No Connection Point. Some people don’t have a choice. They don’t have anything in the .

I have a few large metal junction boxes 4"x4" by 2" deep. I am connecting 6 different 12 gauge romex cables in each box so I have a total of 6 12 gauge ground wires and a ground wire extending from the green grounding screw. Looking for a way to connect 3 sets of #6 in a junction box. Swim Spa calls for the wire to come from the disconnect into a junction box and then into the 2 pumps. I was thinking these Polaris multitap connectors would be the best solution but open to all suggestions! Also I originally thought a 6x6 box would be ok but maybe 8x8? The green ground goes to the junction box and the free end of the braided ground should go to the fixture. Normally one wire per screw. The green wire can loop around the junction box grounding screw and then the end of it can be wire nutted to the free end of the braided wire. Drilling holes in brackets is a no no. As NoSparksPlease suggests, loosen the cable clamp and give a gentle tug to see if you can gain any length. If you hit the jackpot, trim the long wires to a suitable length (no shorter than 6") and reattach them. Otherwise, detach whichever ground remains the longest and use a wire nut or better connector to add a new jumper for the screw and your switch ground.

All the romex leading into the breaker box has a neutral leading to the bus bar and a hot leading to a breaker. All the ground wires are snipped. Advertisement

metal junction box grounding instructions

steel hand carry tool boxes

Hi, sorry I am not good at this. I would like to know if my last image for the ground connection is ok? I am using Kasa smart switches which is UL listed as indicated on the back on the switches. They all have integral ground wires. Box 2,3 and 4 have ground wires coming out of the j boxes, to which I can easily attach the smart switch grounds.

Consolidation of many circuits from breaker panel using nearby junction box. 5. Does every single ground wire in a box have to connect to every other ground wire within the confines of that same box on one branch circuit? 5. . Examples of discrete-space continuous-time dynamical systems The installation manual that came with the Bosch 24 inch 500 series shows how to connect to a cable with 3 wires (copper, white and black), but I only have 2 wires white and black and the grounding is the metal around the cable. The junction box is plastic that I am suppose to connect the white and black wire.

steel index card box

how to ground a metal box

Notching is a metal-cutting process used on sheet-metal or thin bar-stock, sometimes on angle sections or tube. A shearing or punching process is used in a press, so as to cut vertically down and perpendicular to the surface, working from the edge of a work-piece.

where to connect ground wire time warner junction box|basement metal junction box wiring