sheet metal optimizer Acronym Definition; SMO: Server Management Objects: SMO: Social Media Optimization: SMO: SQL Management Objects: SMO: Santa Monica Municipal Airport: SMO: Sabhal Mòr Ostaig (Scotland Gaelic college): SMO

Utilize filler metals (wires) that are slimmer as compared to reedy sheet metal. Numerous welders utilize 0.023-inch diameter wires and 0.024 inches for slimmer sheet metals. 18-gauge metals such as stainless steel have wire diameters of 0.030 and 0.034 inches. Align your torch angle to stop burnout in the SCT model.

0 · wood cut list optimizer

1 · steel cut list optimizer

2 · sheet metal cutting calculator

3 · sheet material calculator

4 · sheet cutting optimizer excel free

5 · free sheet optimizer

6 · cut list optimizer free online

7 · cut list optimizer free

Color coded terminals in the ABS box provides a fast, easy way to connect the wires from the trailer connector to the wiring for either a 6-way or 7-way connector. Makes replacing your trailer's connector simple. Videos are provided as a guide only. Refer to manufacturer installation instructions and specs for complete information. Hi everyone.

wood cut list optimizer

outdoor security light plus junction box

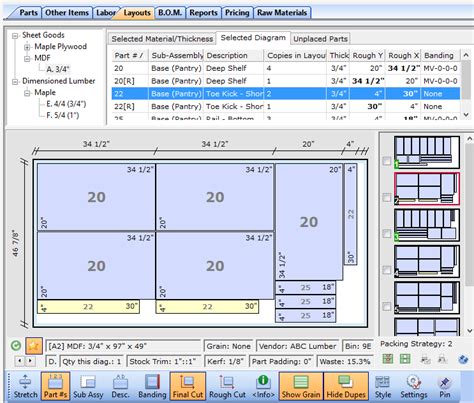

CutList Optimizer is an application targeted for panel cutting optimization. It generates optimized cutting patterns based on the available stock sheets by nesting the required parts.CutList Optimizer is an application targeted for panel cutting optimization. It .Online panel cutting optimization software. Generate optimized cutting patterns .Powerful cutlist optimizer designed to find optimal cut layouts. Type the sheet length and width, cutting kerf and required panel sizes and quantities. Cutlist optimizer will generate optimal .

Units must be consistent for saw, stock & parts. Use a positive number to decrease the part size. Trim is applied to all sides. CutList Optimizer V2: Efficiently calculate sheet, linear & roll material layouts with advanced nesting .

Acronym Definition; SMO: Server Management Objects: SMO: Social Media Optimization: SMO: SQL Management Objects: SMO: Santa Monica Municipal Airport: SMO: Sabhal Mòr Ostaig (Scotland Gaelic college): SMO Sheet Metal Forming Optimization . DOI link for Sheet Metal Forming Optimization. Sheet Metal Forming Optimization. Bioinspired Approaches By Ganesh M. Kakandikar, Vilas M. Nandedkar. Edition 1st Edition. First Published 2017. eBook Published 24 October 2017. Pub. Location Boca Raton. Imprint CRC Press.How is Sheet Metal Optimizer (software) abbreviated? SMO stands for Sheet Metal Optimizer (software). SMO is defined as Sheet Metal Optimizer (software) somewhat frequently.2D Nesting Optimizer - GoNest 2D . Sheet Metal layout and fabrication, Wood working, Building panel, Carpet, PCB, acrylics etc. Whether your stock is in the form of Sheets or Coils (rolls), once you define your cutting job, the layout software requires just one mouse click to arrange the parts on appropriate stocks. It .

Cutlist Optimizer App Cut list optimizer for iOS / iPhone. SmartCut calculates efficient cut list diagrams for your sheet & linear materials. It reduces waste and will save you money. Works with plywood, MDF, glass, plastic, metal, fabric or any other material. Powered by an intelligent algorithm which is faster and more efficient than software .

Automatic line merging. Deepnest packs your parts into a compact area to save material and time. It automatically merges common lines so the laser doesn't cut the same path twice.Multiple Sheet & Panel varieties for a single optimization process. Maximum Yield optimization feature to minimize material wastage. Minimum Layouts optimization feature to minimize the number of cutting patterns generated so as to minimize the number of machine settings. Three Modes viz. Normal, High & Ultra. Support for machine Blade length.This online cut list optimizer is kind of cutting optimization software specialized for cutting rectangular material like wood, glass or sheet metal. Easy to use plywood cut calculator. In industry, 2D cutting stock problem is one of the most important tasks how to cut sheet material with maximal material yield and minimal waste.

steel cut list optimizer

CutMaster 2D is a professional rectangular nesting software package. It enables you to maximize the use of material by generating optimized cutting layouts, using advanced algorithms.It is specially adapted for efficient use in sheet metal, furniture, glass and similar industries. See more at: http://www.goengineer.com/products/solidthinking-inspire/Yuhao He shows us how to effectively use solidThinking Inspire's generative design tool.MetalOpt 8.1 has a new auxiliary brake metal - panel optimizer routine to determine the quantity of sheets needed. . MetalOpt 7.1 has an update adding a new fab sheet for the eluCad software used on elumatec saws and programing to create the eluCad DGX native file to be used directly on their software. 1. Added eluCad functions.This online cut list optimizer is kind of cutting optimization software specialized for cutting rectangular material like wood, glass or sheet metal. Easy to use plywood cut calculator. In industry, 2D cutting stock problem is one of the most important tasks how to cut sheet material with maximal material yield and minimal waste.

The machining trajectory of the irregular contour is usually discretized into straight lines and arcs, and process parameters selection affects the quality and efficiency of irregular sheet metal parts machining. To guide parameters selection of irregular sheet metal parts milling, a multi-objective optimization framework for efficiency and side machining quality is .

Optimizer for Anyshape is the most powerful Profile Nesting Software for getting optimal nesting layouts with minimal waste. Optimizer for Anyshape is designed to automatically place rectangular or non-rectangular shapes in an optimal pattern. . FastCUT Metals Optimizer latest update: April 14, 2014. . Key Details of FastCUT Metals Optimizer. Optimize cutting plans for sheet, plate, and length based layouts. . Use for metal, timber .

Analysis and Optimization of Sheet Metal Forming Processes comprehensively covers sheet metal forming, from choosing materials, tools and the forming method to optimising the entire process through finite element .SMO - Sheet Metal Optimizer. The abbreviation SMO stands for Sheet Metal Optimizer.It is commonly used in various contexts. Whether you're looking for detailed explanations or just a quick definition, this page aims to provide comprehensive information on SMO.True shape Nesting Optimizer - Any profiles Nesting Optimizer - GoNest Profile . True shape nesting and optimizing software. . Sheet Metal layout and fabrication, Wood working, Building panel, Carpet, PCB, acrylics etc. Whether your stock is in the form of Sheets or Coils (rolls), once you define your nesting job, the layout software requires .Optimate App

In this paper Topology optimization is applied using Altair inspire to optimize the Sheet metal Angle bracket. Different results are conducted the better and final results are fulfilling the goal of the paper which is minimizing the mass of the sheet metal part by 65.9% part and Maximizing the stiffness with Better Results of Von- Miss Stress .Sheet Lightning is a specialised engineering 2D/3D CAD System for creating and unfolding sheet metal designs for fabrication or manufacture. It handles cylinders, cones, square-to-round adapters, ovals, intersections and mutli-intersections.

He has completed his Ph.D. from Swami Ramanand Teerth Marathwada University, Nanded. He has total 19 years of teaching experience. His area of expertise are Sheet Metal Forming, Optimization Technique and CAD/CAM/CAE. He has 55 National and International publications. He has Authored three International books. Dr. Vilas M. NandedkarAnalysis and Optimization of Sheet Metal Forming Processes comprehensively covers sheet metal forming, from choosing materials, tools and the forming method to optimising the entire process through finite element analysis and computer-aided engineering. Beginning with an introduction to sheet metal forming, the book provides a guide to the various techniques used .Part optimization. Laser welding part design; Fixture design for laser welding; Tube part design; Fixture design for arc welding . cheaper, or more functional: How would you like your parts? When sheet metal parts have a well-thought-out design, this allows your machines for laser cutting, punching, or bending to reach their full potential . PDF | The research presented in this paper is the modelling and validation of sheet metal forming process using the finite element method to investigate. | Find, read and cite all the research .

Often, obtaining the definition of the blank is not the end of the blanking workflow. Depending on the manufacturing process the engineer has in mind, they need to think about how they will cut the blanks out from a roll of sheet metal. They may also elect to use simpler shapes such as rectangles and trapezoids and worry about trimming later. Sheet Metal Optimization with FEA | Fixing Enclosure Failure. Success Story. In recent years, cloud-based computer-aided engineering (CAE) has become an important tool in the product development cycle. Today, CAE is used extensively in many industries, such as Automotive, Aerospace, HVAC, Manufacturing, Electronics, and Energy. It not only .

On this page are several diagrams that can be used to map 4-way and 3-way lighting circuits depending on the location of the source in relation to the switches and lights. Also included are a 4-way dimmer switch diagram and an arrangement to control lights from four different locations.

sheet metal optimizer|sheet cutting optimizer excel free