axis identification of cnc machine In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the . U Brackets for 1" Panels, 10 Pcs U Bracket for Mounting Stamped Alloy Steel, Thickness 0.1 inch Installation U Shaped Fasteners Brackets, 1⅛ x 1⅛ x 1¾ Inch (30x30x45mm)

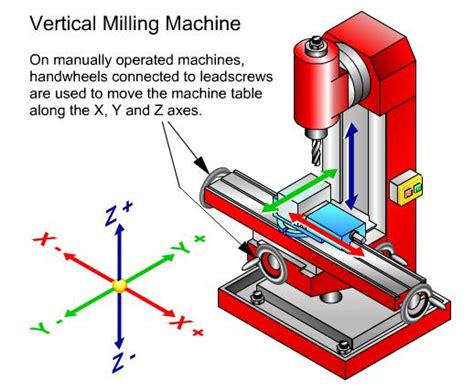

0 · milling machine axis diagram

1 · cnc turning machine axis

2 · cnc mill axis diagram

3 · cnc machine axis locations diagram

4 · cnc machine axis direction

5 · cnc lathe axis explained

6 · cnc axis chart

7 · 5 axis cnc machine diagram

Spacers should be placed between the TV and its mounting bracket, not against the bolt-like washers. To use spacers, first measure the necessary length using a skewer and marks from the bottom of the TV bracket to the surface of the TV. Then, select the right bolts for the spacers, ensuring they fit without piercing the TV’s back.

milling machine axis diagram

There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool .In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the .

painting sheet metal

One crucial aspect of CNC machines is the Axis Identification, which determines the direction and movement of the cutting tool or workpiece. In this blog post, we will delve into the details of . Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even . Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3-axis CNC machine lays the foundation for most CNC machining. As the name suggests, .

CONSIDERED AN AXIS ONLY WHEN CONTROLLED FROM TAPE / CD INSTRUCTIONS AND HAVING OPEN LOOP OR CLOSED LOOP DRIVE. MOTIONS OF NC M/T IN X,Y AND Z .Overview of the primary axes: X, Y, and Z. Importance and applications of each axis in CNC machining. Working with multiple axes (4-axis, 5-axis) and their benefits. 4. Absolute vs. .

At its core, an axis in a CNC machine refers to a direction along which the cutting tool or workpiece moves. Most CNC machines operate in a 3-axis system, but some advanced .CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth). In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool along the length of the workpiece.In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the role and significance of the X, Y, Z, and additional axes, as well as the potential of multi-axis and specialized machines, you now possess the knowledge necessary .One crucial aspect of CNC machines is the Axis Identification, which determines the direction and movement of the cutting tool or workpiece. In this blog post, we will delve into the details of Axis Identification, exploring each axis and its significance in CNC machining. Body: I. Introduction to Axis Identification\ A. Definition and Importance\ Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even controlling more than 10 axes.

Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3-axis CNC machine lays the foundation for most CNC machining. As the name suggests, it can .CONSIDERED AN AXIS ONLY WHEN CONTROLLED FROM TAPE / CD INSTRUCTIONS AND HAVING OPEN LOOP OR CLOSED LOOP DRIVE. MOTIONS OF NC M/T IN X,Y AND Z DIRECTIONS HAVE BEEN STANDARDIZED AND ARE FOLLOWED BY MANUFACTURERS. IT IS THE RELATIVE MOTION OF THE CUTTING TOOL W.R.T. THE W/P THAT DETERMINES .Overview of the primary axes: X, Y, and Z. Importance and applications of each axis in CNC machining. Working with multiple axes (4-axis, 5-axis) and their benefits. 4. Absolute vs. Relative Coordinate Systems: Difference between absolute and relative coordinate systems. Pros and cons of each system. Practical examples of when to use each system. At its core, an axis in a CNC machine refers to a direction along which the cutting tool or workpiece moves. Most CNC machines operate in a 3-axis system, but some advanced machines use 5 or more .

CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth). In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better. There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool along the length of the workpiece.

In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the role and significance of the X, Y, Z, and additional axes, as well as the potential of multi-axis and specialized machines, you now possess the knowledge necessary .One crucial aspect of CNC machines is the Axis Identification, which determines the direction and movement of the cutting tool or workpiece. In this blog post, we will delve into the details of Axis Identification, exploring each axis and its significance in CNC machining. Body: I. Introduction to Axis Identification\ A. Definition and Importance\ Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even controlling more than 10 axes. Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3-axis CNC machine lays the foundation for most CNC machining. As the name suggests, it can .

CONSIDERED AN AXIS ONLY WHEN CONTROLLED FROM TAPE / CD INSTRUCTIONS AND HAVING OPEN LOOP OR CLOSED LOOP DRIVE. MOTIONS OF NC M/T IN X,Y AND Z DIRECTIONS HAVE BEEN STANDARDIZED AND ARE FOLLOWED BY MANUFACTURERS. IT IS THE RELATIVE MOTION OF THE CUTTING TOOL W.R.T. THE W/P THAT DETERMINES .Overview of the primary axes: X, Y, and Z. Importance and applications of each axis in CNC machining. Working with multiple axes (4-axis, 5-axis) and their benefits. 4. Absolute vs. Relative Coordinate Systems: Difference between absolute and relative coordinate systems. Pros and cons of each system. Practical examples of when to use each system. At its core, an axis in a CNC machine refers to a direction along which the cutting tool or workpiece moves. Most CNC machines operate in a 3-axis system, but some advanced machines use 5 or more .

cnc turning machine axis

cnc mill axis diagram

pancake junction box

cnc machine axis locations diagram

David Jones Elizabeth Street and Market St Sydney stores will open at 5am on Boxing Day, with the official bell ringing at Elizabeth St. Westfield Bondi Junction. Boxing Day 7am — 9pm

axis identification of cnc machine|cnc lathe axis explained