how to calculate gauge of sheet metal Pure metal / Used as an alloy element for aluminum, lead, zinc, and other . According to the latest North America metal fabrication market analysis, technological advancements have led to a surge in emphasis on accuracy, efficiency, and innovation. These advancements, which include automated machinery and cutting-edge software, have transformed metal manufacturing.

0 · steel sheet gauge size chart

1 · standard sheet metal gauge chart

2 · printable sheet metal gauge chart

3 · most common sheet metal gauge

4 · metal plate gauge thickness chart

5 · metal gauge sizes chart

6 · gauge chart stainless steel sheet

7 · galvanized sheet steel gauge chart

You can just do a jumper wire from the box to the receptacle. You want to ground the box first before the receptacle so that way if you remove the receptacle you don’t break the .

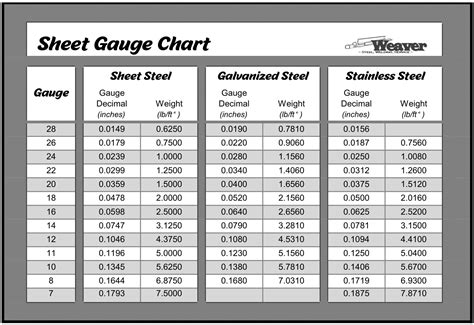

The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.Pure metal / Used as an alloy element for aluminum, lead, zinc, and other . Ga. is different from inches, there is no conversion formula. Even when the non .Sheet metal thickness gages are based on a weight of 41.82 pounds per square foot per inch of thickness. This is known as the Manufacturers' Standard Gage for Sheet Steel, and is primarily .

steel sheet gauge size chart

standard sheet metal gauge chart

A sheet metal gauge chart provides essential information that lets you choose accurate material measurements in construction, manufacturing, and engineering. Using these charts can help you enhance the quality of your . Here’s why: Durability. The gauge of metal significantly influences the durability of your project or design. Thicker metal can withstand more wear and tear, making it essential for .

The numbers of a steel gauge chart typically range between 3-30. Yet those numbers do not indicate a specific dimensional value. Standard gauge sizes were developed based on the weight of the sheet for a given material and the .

Calculating steel gauge in inches requires knowing the type and standard weight of the steel and measuring the weight of a sample. Gauge can be specified in inches or .

A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material thicknesses for various metals. Understanding how to interpret these charts is crucial for . A gauge conversion chart can be used to determine the actual thickness of sheet metal in inches or millimeters. For example, 18 gauge steel, according to a gauge conversion chart, is 0.0478 inch or 1.214 millimeter. Sheet metal gauge (or gage) numbers refer to the thickness of sheet metal. This thickness is measured in either mm or in thousandths of an inch (in). The higher the gauge, the thinner the sheet metal (except for Zinc). The .

I tried your calculator using 12×12 duct 48”long. .0239 as gage thickness for 24 ga galvanized sheet metal. It weighs 1lb per square foot. I thought I could check accuracy with a known value. The answer comes out as .

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This . For example, a 14-gauge metal sheet is thicker and stronger than an 18-gauge sheet. Different standard gauges exist for different metal materials. For example, non-ferrous metal uses the American Wire Gauge (AWG) . The Gauge to mm Calculator is a valuable tool for converting gauge measurements to millimeters, which is commonly used in industries like metalworking, manufacturing, and construction. . This specific formula applies to sheet metal gauges. Wire gauges may use different standards. 6. Can I convert mm back to gauge using this tool?Interact with our Coil & Sheet Calculators for your next project. Contact us for more information or to request a free quote. Interact with our calculators for your next project. Products. . Gauge (inches) Weight = lbs. Reset. Maximum Coil OD. ID (inches) Width (inches) Weight (lbs) OD = in. PIW = lbs/in of width. Reset. Flat Sheet Weight .

For materials such as Aluminum and Brass the thicknesses will be different. Thus a 10 gage steel sheet which has a thickness of 0.1345 inch will weigh 41.82*0.1345 = 5.625 pounds per square foot. In the U.S the most common sheet metal gage specified is the Steel Gage. In the U.K. the most common sheet metal gage is the British Standard Wire Gage.When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the Using a caliper, measure the thickness of the expanded metal sheet or panel. This will help you determine the gauge or wire diameter of the material. Expanded metal is defined by its mesh size, which refers to the distance between two adjacent strands. Measure the mesh size using a ruler or tape measure. Step 3: Calculate Strand Thickness

printable sheet metal gauge chart

The K-Factor in sheet metal working is the ratio of the neutral axis to the material thickness. . The K-Factor is used to calculate flat patterns because it is directly related to how much material is stretched during the bend. . For our example let’s take a piece that is 14 Gauge, .075”, 4” Wide and 12” Long. .

This K-factor calculator will assist you in finding the K-factor for sheet metal. Sheet metal is the building block of structures, from forming the body of automobiles to the skin of aircraft wings. The roofs on the house (cf. roofing calculator) or the geyser that supplies water for your warm showers and baths all use sheet metal for the fabrication process. Learn about the different options available in SOLIDWORKS for calculating a sheet metal flat pattern and what these different options mean. This video also d.

From a fabricator perspective that’s cool to know about the 1/4-20 versus 1/4-14 screws — makes sense. With a self drilling screw, the 1/4-14 screw makes a hole the same size as minor diameter of the screw b/c the sheet metal deforms to fit between the threads.

Sheet metal thickness is often specified using the gauge system, which assigns a numerical value to represent the thickness. The gauge number is inversely proportional to the thickness, meaning a higher gauge number indicates a . Recently we dialed in our K factors, which on 7-gauge and thicker materials has been lower than I had ever seen (K ≈ 0.22 in.), which I’m attributing to the aforementioned punch radius. I’ve been trying to come up with a way to tell our brake operators where to set the backstops when they need to place a previous bend against them.The sheet metal gauge calculator is a valuable tool in the HVAC industry as it helps engineers, technicians, and contractors to accurately determine the thickness of sheet metal, which is critical for designing and installing HVAC . How thick is 6 gauge plate? 6-gauge plate is about 0.1875 inches (4.76 mm) thick. How thick is 9 gauge sheet metal? 9-gauge sheet metal is about 0.1495 inches (3.80 mm) thick. What does the number mean on expanded metal? The number in expanded metal notation typically refers to the gauge or thickness of the material.

For sheet metal less than 4mm thick, a die opening of 6 to 8 times the material thickness; For sheet metal over 4mm thick, a die opening of 8 to 12 times the material thickness. Therefore, the desired internal R-angle for a bent workpiece can be achieved by considering the material properties in conjunction with the choice of die opening. Calibration ensures accurate bend calculations across various material gauges. Tooling Effects: The type and condition of bending tools (e.g., die width, punch radius) affect the material’s deformation characteristics. . Sheet Metal Bending Calculator (Free to Use) Y Factor Calculator; Bend Allowance Calculator; Bend Deduction Calculator .But if you need access to a steel weight calculator in order to get your steel plate weight (or aluminum or stainless steel for that matter) check out our metal weight calculator here. Ryerson: The Metal Supplier of Choice. Ryerson is a leading North American metal supplier that provides more than just metal. We respond to the ever-changing . Bend deduction (BD) is a critical factor in sheet metal fabrication, used to calculate the flat pattern length of a sheet metal part. It accounts for the material that is displaced during the bending process. . The dimensional accuracy of bent workpieces is related to the positional precision of the press brake’s back gauge and the .

To measure the thickness of an expanded metal sheet using a gauge, place the sheet onto a flat surface with one edge resting against a flat edge, ensuring that the sheet is perpendicular to the edge. . Simply input the dimensions of the expanded metal sheet into the calculator, and it will calculate the surface area for you.This calculator is designed to give the approximate weight of sheet metal, based on length, width and thickness. Select the thickness. Enter the length, width and number of pieces.When the sheet metal is bent the inside radius pulls the edge of the material away from the apex of the bend. Because this is a geometrical function it does not change with a metal’s K-Factor the way Bend Allowance and Bend Deduction do. The Inside Setback is closely related to, but should not be confused with, the Outside Setback. The below . Through my website, someone from a manufacturing company asked how to calculate thinning in a sheet metal part made from 2mm thick high strength steel. My response: . The steel mill is allowed to ship product that has some deviation from this gauge – maybe 1.85mm to 2.15mm as an example. So you must get an accurate measurement of the actual .

Nearly all building codes restrict the use of cavity spaces as supply ducts. However, it has been common practice to use cavity spaces as return-air pathways. Building cavities used as return-air plenums is one of the leading causes of duct leakage in homes today.

how to calculate gauge of sheet metal|printable sheet metal gauge chart