how to calculate developed length of sheet metal The distance from the neutral layer to the inner side of the sheet is denoted by λ, and the material thickness is denoted by T. The basic formula for calculating the unfold length: Unfolding length = inner size of material + inner . Metallic fabrics are the preferred material for glitz and glam occasions. They are perfect for cocktail dresses, costumes, and a wide range of astonishing, show-stopping apparel favored by celebrities.

0 · sheet metal flat length formula

1 · sheet metal development length calculator

2 · sheet metal design length formula

3 · sheet metal bend length calculator

4 · metal sheet development formula

5 · metal sheet development calculation

6 · how to calculate sheet metal

7 · calculate the development of a sheet

Sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other features in sheet metal. The punch is a tool pressed into the sheet metal, while the die supports the sheet metal during the punching process.

Once the material has been folded we have a deformation of it, technically we call it BENDING FIBERS. Therefore there is an external area where the material has been lengthened resulting in TRACTION FIBERS and an internal part where the material has been shortened, COMPRESSION FIBERS. But just between . See moreThere are many methods to calculate the position of the neutral fiber, but we believe that the following table is very practical, since it perfectly defines that its position basically depends on . See moreAs the sheet is a “live” material and the bending action depends on many factors (thickness of the material, quality and type of material, width of the die and a large etc), it is . See more The distance from the neutral layer to the inner side of the sheet is denoted by λ, and the material thickness is denoted by T. The basic formula for calculating the unfold length: Unfolding length = inner size of material + inner .

SolidWorks II Sheet Metal II Total Developed Length (Flat Length) Calculation.In this video, I am going to explain, how to calculate Total Developed length . K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of the .

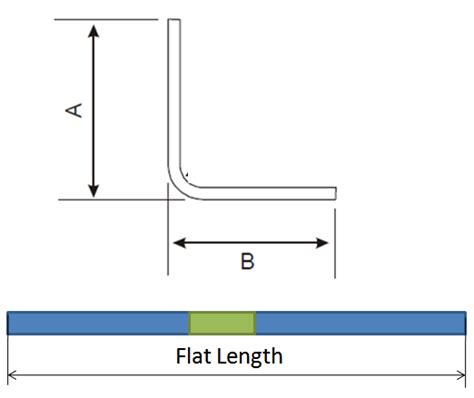

Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = . To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: (Outside Diameter – Thickness) x 3.1416 = Length of Plate Required. (Inside Diameter .

Learn how our tool simplifies complex developed length calculations, ensures precision, and enhances your fabrication tasks. Dive into DIN 6935 guidelines for bending, radii, and . Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [ (0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend .Depending on the type of developable geometry, you can use one of the following methods to calculate the developed length for a sheet metal part or feature: • System-defined equation .

You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length . To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: (Outside Diameter – Thickness) x 3.1416 = Length of Plate Required (Inside Diameter + . I have a sheet with bend wall. Now after unbend the total length of the sheet should be including the radius of the bend. E.g. Sheet is of 100X100 and bend wall attached is of 100X50 with radius = thickness. After unbend .

How to calculate the value of material shrinkage. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet metal blank initial flat length, from the finished part measurements. You only have to insert interior angle, flange lengths, K factor, inside radius, and material thickness.To sum up, This calculator can be used to calculate sheet metal flat length. Sheet metal flat pattern is calculated using the k factor. k factor value can be calculated by the reverse-engineering method. We will keep adding more information on the sheet metal flat pattern calculator. Please share your suggestions, comments, or questions in the .

How to calculate sheet metal flat length by using CAD software (Pro-Engineer or Creo) and Theoretical with physics based formulas.

The second flat-blank-development example adds the two dimensions (from edge to the apex), and subtracts a bend deduction. In this case, the calculations use a complementary angle for the OSSB, and the dimensions are called from the edge to the apex—again, as specified in Figure 4.. Outside Setback (OSSB) Developed length refers to the length of the unstretched fiber measured over both bent and straight sections of a bent sheet. Bend allowance is a term coined by Sachs as a measure of the length of the unstretched fiber in the bent section. Sachs’ empirical equation for calculating bend allowance is not physically based and is independent of material and forming .Bend allowance calculations are used to determine the developed length of flat sheet metal required to make a bend with a specific radius and angle. These calculations are important to create an accurate flattened model for manufacture. . You can use the following system-defined equation to calculate developed length for a part or wall .

sheet metal flat length formula

(For a deep dive into the k-factor, check out “Analyzing the k-factor in sheet metal bending.”) You’ll need the k-factor to calculate the bend allowance (BA), or the distance around the bend at the neutral axis. You can calculate it using this empirical formula, which incorporates the common k-factor of 0.4468:

You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length of the part.The calculated tension and compression in any bar at any section shall be developed on each side of the section by an appropriate development length or end anchorage or by a combination thereof. . Calculate the development length of the steel having M-25 grade of concrete, Fe415 grade of steel rod, and the diameter of the steel rod is 12mm. Development length or Blank size calculation is a typical problem in sheet metal fabrication, and other metal forming industries, many people are struggling to find the length of the exact sheet .

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

How to calculating Blank size of a sheet matel for rolled | Mechanical EngineeringIn this interactive object student read how to calculate the blank size for.Sheet Metal and Plastic Bending Calculator. . Enter your base length. This represents the overall outside desired dimension of the base, center, or largest section of the part. . The K-factor in sheet metal bending represents the ratio . Can anyone help me to calculate the developed length in Creo/ProE Sheetmetal. Thanks in Advance. Amit. This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new . Hi Friends,In this video you will learn how to calculate sheet metal flat length, bend allowance and outside setbackCheck out Playlist videos from mechanical.

Metal weight calculator online - free steel weight calculator. Has pre-entered densities for dozens of commonly-used metals and metal alloys like steel, aluminum, nickel, iron, copper, cadmium, gold, silver, etc. Calculate the weight of a steel beam, bar, tube, profiles, channels, or a .The "Metal Roof Sheet Length Calculator" is a web-based tool designed to assist individuals with calculating the necessary length of metal roof sheets for their projects. This calculator is significant as it saves time and helps to avoid the mistakes commonly associated with manual calculations.

The sheet metal blank size is determined by considering factors like part dimensions, material thickness, bend allowance, stretch allowance, bend radius, minimum bend distance, material properties, K-factor, drawing ratio, setback, tooling, tolerances, part complexity, and material utilization efficiency. Accurate calculations ensure efficient use of material and .

Kansas City Plant 2193 Manchester Trfy. Kansas City, Missouri 64126 Phone: 816-483-7575 Fax: 816-483-1826 Issue: In sheet metal => the sheet metal unfold rule is based on a defined bend table => when a flat pattern is generated => you would like to know how the flat pattern length is calculated.

sheet metal development length calculator

Creo Sheet Metal Tutorial : This video to describe setting of K factor in CREO and how to change Developed length of Sheet metal parts.K-Factor is an importa.

In This Tutorials We'll Discuss blank size calculation or how to develop Blank length.Our Other Sheet Metal tutorials1) https://www.youtube.com/watch?v=7xT4W.Roll Diameter Calculator. Conclusion. Plate rolling is a versatile metal fabrication technique that allows for the bending and shaping of metal plates to create various components and structures. By understanding the plate rolling formula and employing appropriate calculation methods, fabricators can determine the required bend radius, length, and thickness for a successful .Student will able to understand the concept of Developed length due to bending

Causes: More material is stretch when is compresses, which lead in part being longer after bending. The K-Factor depends on: Bend angle; Material of sheet metal part

It is a bridge in which the main beams comprise girders in the shape of a hollow box (rectangular or trapezoidal shape). The box girder normally comprises either prestressed concrete, structural steel, or a composite of steel and reinforced concrete.

how to calculate developed length of sheet metal|calculate the development of a sheet