cnc machine operation procedure CNC machining involves the use of computerized controls to operate and manipulate machine tools, resulting in precise cuts, shapes, and finishes on materials like metal, plastic, wood, and composites. Specify number required at time or order. FITTING OPTIONS: Brass, nickel plated PG11 Liquid Tight. INTERNAL CONNECTOR: Teal high temperature thermal plastic housing with stainless steel barrel lugs and 3M dielectric sealing tape; 200 watt maximum load.

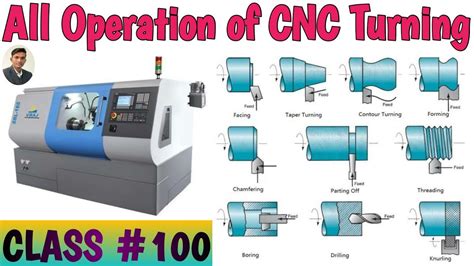

0 · types of cnc operations

1 · different types of cnc machines

2 · cnc machine setup operator

3 · cnc machine operator meaning

4 · cnc machine operations list

5 · cnc machine operation basics

6 · cnc machine operating instructions

7 · cnc machine basic knowledge

Hon'ble Union Minister of Coal & Mines. Name: Shri G. Kishan Reddy. Constituency : Secunderabad , Telangana. Party Name : Bharatiya Janata Party(BJP) Email Address : gkishanreddy[at]yahoo[dot]com kishanreddy[dot]g[at]sansad[dot]nic[dot]in. Father's Name Late Shri G. Swamy Reddy. Mother's Name Late Smt. G. Andalamma. Date of Birth 15-Jun-1960

This standard operating procedure (SOP) provides comprehensive guidelines for operating a CNC machine and outlines the key steps to be followed during machine setup, programming, and maintenance. Step 1: Machine SetupStep-by-step guide on creating customized SOPs tailored to your CNC machines. .CNC machining is a widely used manufacturing technique that involves .• Do not power the machine to tighten or loosen cutting bits or tools. • Work pieces and stock must be rigidly fastened to the mill bed with clamps, a vise, or special fixtures. • Use appropriate .

types of cnc operations

different types of cnc machines

CNC machining involves the use of computerized controls to operate and manipulate machine tools, resulting in precise cuts, shapes, and finishes on materials like metal, plastic, wood, and composites.Understand the CNC Operation. List the steps to set up and operate a CNC mill. Identify the location and purpose of the operating controls on the Haas CNC Mill control.Step-by-step guide on creating customized SOPs tailored to your CNC machines. Identification of key operational processes and tasks. Documentation of machine setup and calibration .

This article breaks down the basics of CNC machine operation, from powering up to navigating the control panels. Discover essential functions like program editing, tool setting, and emergency protocols.

CNC machines work by following programmed instructions and can use multiple tools simultaneously. The most common CNC machine language is G-code. CNC machines can be classified into different types such as CNC .CNC machining is a widely used manufacturing technique that involves the use of computer-controlled machines to shape and fabricate various materials. From metal to plastics, CNC .CNC Machining is often the last step in metal manufacturing, or sometimes the only process involved. Compared to other metalworking techniques, CNC machining is capable of meeting .

boxer steel

cnc machine setup operator

boxer metal

This standard operating procedure (SOP) provides comprehensive guidelines for operating a CNC machine and outlines the key steps to be followed during machine setup, programming, and maintenance. Step 1: Machine Setup• Do not power the machine to tighten or loosen cutting bits or tools. • Work pieces and stock must be rigidly fastened to the mill bed with clamps, a vise, or special fixtures. • Use appropriate speeds and feeds for the type and size of cutter being used and the material being machined. • Make sure the cutting tool is clear of the work .CNC machining involves the use of computerized controls to operate and manipulate machine tools, resulting in precise cuts, shapes, and finishes on materials like metal, plastic, wood, and composites.Understand the CNC Operation. List the steps to set up and operate a CNC mill. Identify the location and purpose of the operating controls on the Haas CNC Mill control.

To operate a CNC machine, you need to first understand the software that controls it. Take the time to get acquainted with the specific software package used by your CNC machine manufacturer. Read the user manual, watch tutorial videos, and explore the different features and functions. CNC programming is a crucial skill for operating a CNC machine.

Step-by-step guide on creating customized SOPs tailored to your CNC machines. Identification of key operational processes and tasks. Documentation of machine setup and calibration procedures. Documentation of material loading and tooling setup. Definition of machining parameters (speeds, feeds, depths of cut, etc.). This article breaks down the basics of CNC machine operation, from powering up to navigating the control panels. Discover essential functions like program editing, tool setting, and emergency protocols. CNC machines work by following programmed instructions and can use multiple tools simultaneously. The most common CNC machine language is G-code. CNC machines can be classified into different types such as CNC mills, CNC turning centers, plasma cutters, and water jet cutters.

CNC machining is a widely used manufacturing technique that involves the use of computer-controlled machines to shape and fabricate various materials. From metal to plastics, CNC machining offers precise and efficient results.CNC Machining is often the last step in metal manufacturing, or sometimes the only process involved. Compared to other metalworking techniques, CNC machining is capable of meeting the tightest tolerances, and producing the most accurate, precise products with a .This standard operating procedure (SOP) provides comprehensive guidelines for operating a CNC machine and outlines the key steps to be followed during machine setup, programming, and maintenance. Step 1: Machine Setup

cnc machine operator meaning

• Do not power the machine to tighten or loosen cutting bits or tools. • Work pieces and stock must be rigidly fastened to the mill bed with clamps, a vise, or special fixtures. • Use appropriate speeds and feeds for the type and size of cutter being used and the material being machined. • Make sure the cutting tool is clear of the work .

CNC machining involves the use of computerized controls to operate and manipulate machine tools, resulting in precise cuts, shapes, and finishes on materials like metal, plastic, wood, and composites.

Understand the CNC Operation. List the steps to set up and operate a CNC mill. Identify the location and purpose of the operating controls on the Haas CNC Mill control.

To operate a CNC machine, you need to first understand the software that controls it. Take the time to get acquainted with the specific software package used by your CNC machine manufacturer. Read the user manual, watch tutorial videos, and explore the different features and functions. CNC programming is a crucial skill for operating a CNC machine.Step-by-step guide on creating customized SOPs tailored to your CNC machines. Identification of key operational processes and tasks. Documentation of machine setup and calibration procedures. Documentation of material loading and tooling setup. Definition of machining parameters (speeds, feeds, depths of cut, etc.). This article breaks down the basics of CNC machine operation, from powering up to navigating the control panels. Discover essential functions like program editing, tool setting, and emergency protocols.

CNC machines work by following programmed instructions and can use multiple tools simultaneously. The most common CNC machine language is G-code. CNC machines can be classified into different types such as CNC mills, CNC turning centers, plasma cutters, and water jet cutters.CNC machining is a widely used manufacturing technique that involves the use of computer-controlled machines to shape and fabricate various materials. From metal to plastics, CNC machining offers precise and efficient results.

boxer metal twin turbo

Hook wire to the supplied junction box on the bottom of the dishwasher through an approved connector. Make your joints to the dishwasher wires. Push dishwasher back into place and secure.

cnc machine operation procedure|cnc machine operations list